TM and TM again --

Page 64

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

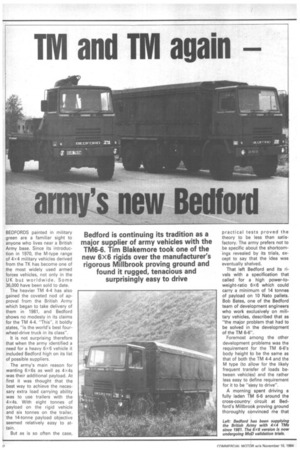

Bedford is continuing its tradition as a major supplier of army vehicles with the TM6-6. Tim Blakemore took one of the new 6x6 rigids over the manufacturer's rigorous Mil!brook proving ground and found it rugged, tenacious and surprisingly easy to drive

BEDFORDS painted in military green are a familiar sight to anyone who lives near a British Army base. Since its introduction in 1970, the M-type range of 4x4 military vehicles derived from the TK has become one of the most widely used armed forces vehicles, not only in the UK but worldwide. Some 36,000 have been sold to date.

The heavier TM 4-4 has also gained the coveted nod of approval from the British Army which began to take delivery of them in 1981, and Bedford shows no modesty in its claims for the TM 4-4. "This", it boldly states, "is the world's best fourwheel-drive truck in its class".

It is not surprising therefore that when the army identified a need for a heavy 6x6 vehicle it included Bedford high on its list of possible suppliers.

The army's main reason for wanting 6x6s as well as 4x4s was their additional payload. At first it was thought that the best way to achieve the necessary extra load carrying ability was to use trailers with the 4x4s. With eight tonnes of payload on the rigid vehicle and six tonnes on the trailer, the 14-tonne payload objective seemed relatively easy to attain.

But as is so often the case, practical tests proved the theory to be less than satisfactory. The army prefers not to be specific about the shortcomings revealed by its trials, except to say that the idea was eventually shelved.

That left Bedford and its rivals with a specification that called for a high power-toweight-ratio 6x6 which could carry a minimum of 14 tonnes of payload on 10 Nato pallets. Bob Bates, one of the Bedford team of development engineers who work exclusively on military vehicles, described that as "the major problem that had to be solved in the development of the TM 6-6".

Foremost among the other development problems was the requirement for the TM 6-6's body height lo be the same as that of both the TM 4-4 and the M type (to allow for the likely frequent transfer of loads between vehicles) and the rather less easy to define requirement for it to be "easy to drive".

A morning spent driving a fully laden TM 6-6 around the cross-country circuit at Bedford's Mil[brook proving ground thoroughly convinced the that

the latter requirement certainly has been met. After only minutes behind the wheel I felt confident enough to tackle Mil!brook's three-mile metalled road hill circuit. This includes a range of gradients from seven per cent to a suddenly steepening 27 per cent.

In a still unfamiliar vehicle I would not have been surprised to miss a gear on my first lap, and even with up to 206hp and 500Ibft of torque on tap from the Blue Series 8.2-litre Bedford engine that would have led, inevitably, to a stall. The fact that the TM 6-6 kept rolling over even the severest of Mil[brook's gradients is a tribute to how easy its ZF S6-80 synchromesh, six-speed gearbox is to use.

Clearly it is in the interests of Bedford and the army for as many TM 6-6 parts as possible to be shared with the TM4-4. But the gearbox is one component that could not be common on both models. In its 4x4 TM, Bedford used a Turner sixspeed synchromesh M6-47026. The reason for turning to ZF for the heavier vehicle was that its deeper first gear ratio (9:1 instead of the Turner's 7.35:1) was needed to give the 24-tonner the required maximum gradeability. This gearbox is already in service with the West

German Army and so would have been familiar to our own Ministry of Defence.

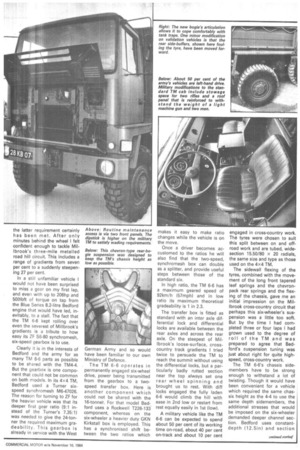

The TM 6-6 operates in permanently engaged six-wheel drive, power being transmitted from the gearbox to a twospeed transfer box. Here is another component which could not be shared with the 16-tonne'r. For that model Bed-, ford uses a Rockwell T226-133 component, whereas on the six-wheeler a heavier duty GKN Kirkstall box is employed. This has a synchronised shift between the two ratios which makes it easy to make ratio changes while the vehicle is on the move.

Once a driver becomes accustomed to the ratios he will also find that the two-speed, synchromesh box can double as a splitter, and provide useful steps between those of the standard six.

In high ratio, the TM 6-6 has a maximum geared speed of 92km/h (57mph) and in low ratio its maximum theoretical gradeability is 1 in 2.3.

The transfer box is fitted as standard with an inter axle differential lock and differential locks are available between the rear axles and across the rear axle. On the steepest of Milbrook's loose-surface, crosscountry track gradients I tried twice to persuade the TM to reach the summit without using the differential locks, but a particularly badly rutted section near the top always set one rear wheel spinning and brought us to rest. With diff locks engaged the fully laden 6-6 would climb the hill with ease in 2nd low or restart from rest equally easily in 1st (low).

A military vehicle like the TM 6-6 can be expected to spend about 50 per cent of its working time on-road, about 40 per cent on-track and about 10 per cent

engaged in cross-country work The tyres were chosen to suit this split between on and offroad work and are tubed, widesection 15.50/80 x 20 radials, the same size and type as those used on the 4x4 TM.

The sidewall flexing of the tyres, combined with the movement of the long front tapered leaf springs and the chevronpack rear springs and the flexing of the chassis, gave me an initial impression on the Mil!brook cross-country circuit that perhaps this six-wheeler's suspension was a little too soft. But by the time I had completed three or four laps I had grown used to the degree of roll of the TM and was prepared to agree that Bedford's suspension tuning was just about right for quite highspeed, cross-country work.

The TM 6-6's chassis sidemembers have to be strong enough to withstand a lot of twisting. Though it would have been convenient for a vehicle which required the same chassis height as the 4-4 to use the same depth sidemembers, the additional stresses that would be imposed on the six-wheeler demanded deeper channel section. Bedford uses constantdepth (12.5in) and section

29ton/sqin-yield stress steel sidemembers on the TM 6-6 — the same as on standard civilian TIV14400 models.

The 4-4 has a 10in-deep frame. The three-leaf chevronpack rear suspension of the sixwheeler was designed to compensate for this difference and bring its chassis height into line with that of the four-wheeler.

Ministry of Defence contracts for the supply of vehicles and bodies have been awarded separately in the past. Now that has changed, and the supplier of the six-wheelers will be expected to be responsible for providing all the bodywork and associated equipment. Bodywork options for the TM 6-6 include a Hudson Wharton hydraulically powered winch and an Atlas hydraulic crane capable of lifting 1,400 kg at 6.55m.

The body itself will be available as a platform and as a dropside with tailboard or with a canvas tilt cover. It was developed, and will be manufactured, by Edbro of Bolton, a company best known for its tip

ping gear.

The computer-aided drafting equipment which was recently installed at Bolton must have helped Edbro's engineers a good deal in solving the tricky problem of keeping the bodyweight within the required limits, yet making it strong and flexible enough to withstand the kind of regular pounding which I sampled very briefly at Millbrook.

Bedford hopes to begin large volume production of its military TM 6-6 in the summer of 1986. Though clearly the number of civilian applications for a vehicle of this kind is limited, a civilian version will be on offer.