Overseas Demand Influeno

Page 42

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

Home Design PART TWO

By THE TECHNICAL EDITORS

APREVIOUS issue of " The Commercial Motor" contained a detailed review of developments and design tendencies of power units and some of the transmission systems, as revealed by an examination of the vehicles exhibited at the Commercial Motor Show. This technical review is concluded by a continuation of the analysis of gearboies fitted to the heavier vehicles and overseas models, and details of the latest in axles, suspension arrangements, braking systems, steering gear arid frames.

To take the high torque of the Gardner 8LW engine, which powers the Atkinson overseas tractor, the chassis maker has developed its own gearbox. It is a five-speed unit, the massive cast-iron case being bolted direct to the engine. In this case top gear is direct drive. A similar box is used in the Atkinson passenger chassis, the high gear in this case being an overdrive of 0.745 to 1 ratio. A feature of the box is that it has one fewer gear trains than is normal, the third and fourth constant-mesh gears rotating on the layshaft and being engaged by a dog clutch. The "ball" change speed lever has been replaced by one having two hardened pins tii)ort which the lever rocks. The lever is secured direct to the single tubular change-speed shaft, so that as it is moved from side to side, it rotates the shaft and so picks up a new selector fork at the gearbox end.

In the new five-speed gearbox, used in the Dennis Falcon and Centaur chassis, the design is such that the splines for the constant-mesh gears can be replaced.

No fewer than 16 forward speeds are made available on the. Foden overseasrtractor chassis. The main gearbox is a four-speed, close-ratio, constant-mesh type, used in conjunction with a preselective-epicyclic unit, which gives a high and a low range on the four ratios. The vehicle has doubledrive third and fourth axles, which can be employed as direct drive or double-reduction units as required. To engage the reduction gear in the hubs, all that is necessary is to turn a trunnion through an angle of 90 degrees.

The new five-speed constant-mesh gearbox in the A.E.C. Mammoth Major incorporates a gear-type oil pump, delivering lubricant to the bushes on which run the second. third and fourth speeds main gear shafts. The six-speed constant-mesh gearbox in the Scammell six-wheeland fourwheel-drive chassis also incorporates a pump. On the Crossley underfloor-erigined chassis, the clutch is hydraulically operated through the medium of a conventional clutch pedal. Interconnected with the clutch release, is a small band brake, which bears on the drum on the clutch B8

shaft when the clutch is disengaged. This arrests the momentum of the spinning clutch plate and shaft, and thus assists in gear changing.

Hypoid and double-reduction axles haveloeen selected by many manufacturers, in their new models, to replace the conventional spiral-bevel or worm-driven units. In some cases, where the hypoid axle has displaced the spiral-bevel gear, this change has been made to provide a heavier-duty unit, whilst the double-reduction gear is reserved maiinly for overseas vehicles, where additional ground clearance may be required.

The A.E.C. overseas .ix-wheeler offers a typical example of the latest in double-bevel-reduction drive, which is provided for both axles of the bogie. Drive from the propeller

shaft is taken to an overhead bevel gear in the forward axle of the bogie, which is in turn connected to the bevel gear of the rearmost axle. In keeping with requirements of operation over rough terrain, the vehicle is equipped with a fully articulated bogie, which is available in place of the balance-beam suspension unit. With this new bogie, the wheels on each side are connected to the ends of a single reversed-camber semi-elliptic spring, which is pivoted about its centre on a tubular beam. There is no third differential.

HyPoid-drive axles have been introduced into many makes of goods and single-deck passenger chassis with gross loads of up to 12 tons. The new Bedford 7-ton range and its accompanying passenger version, the Vulcan 7-tonner and Dodge goods and passenger vehicles incorporate hypoid axles, and these are used in the larger Atkinson underfloor

engined passenger chassis, the Tilling-Stevens Express Mark II and the Dodge overseas coach. In the Atkinson, the drive is offset towards the near side, which makes for an improved transmission line between the gearbox and axle. The new Leyland Royal Tiger has a spiral:bevel drive to the rear axle.

The Dennis Dominant single-decker has a new form of double-reduction axle, in which the drive is taken through a spiral-bevel unit at the centre of the axle case, and the double reduction, through epicyclic gearing, is obtained in the wheel hubs. This hub reduction is, in other cases, used in conjunction with a worm-driven axle, the object here being to minimize lubricant temperatures in the worm pot.

Two-speed axles, few of which were seen at the 1948 Show, are now available on most goods vehicles of the 5-6-ton class, and on comparable chassis for tractors and passenger vehicles. Normally, the standard two-speed axle and operating equipment can be used without modification, but in the Seddon tractor, with Scammell attachments, the operating diaphragmhas been removed from the axle case and attached to the frame to provide sufficient clearance under the coupling gear.

Air-pressure braking systems, judged by the Earls Court exhibits, are gaining popularity, especially in overseas models; in fact, it is almost a rule that overseas operators of heavy goods vehicles and coaches and buses specify, this

i 0 form of braking. As an example of the trend, Sentinel and Atkinson models and the Daimler CD 650 chassis are now being offered with compressed-air equipment. Mostly, the compressors are belt-driven from the transmission or engine, but two notable exceptions are the E.R.F., which has a jackshaft drive between the gearbox and compressor, and the A.E.C. Mammoth Major Mark III, which has a small crank mounted on a rear extension to the gearbox layshaft for compressor operation.

Heavy goods vehicles are generally equipped with the• multi-pull ratchet-type hand brake, which is released by a single forward stroke of the lever. The E.R.F. overseas model has this form of equipment, but the lever has two triggers, operating independent pawls at its base, so that the release can be controlled. During release, the load on the ratchet is transferred from one pawl to the other, in turn.

The Foden eight-wheeled tractor, built for operation in Australia, retains the beam-type suspension for the rear bogie, but the hand-brakc linkage is compensated for axle articulation. The final relay lever is pivoted from the frame, but is linked to the balance beam of the bogie, in addition to the cam-operating levers, and radial movement of the beam causes the operating lever to be moved and compensates the linkage accordingly.

A modification has been made in the transfer box of the Scammell four-wheel-drive chassis, so that the drive to the front axle can be engaged when the occasion demands. Formerly, the front-wheel drive was permanently engaged. The new six-wheel-drive chassis has a rear bogie, which is similar to that of the pre-war Pioneer model. Drive to the bogie is taken to a central unit and transmitted to the wheels through a train of gears, thus permitting an unusually large angle of articulation. The gear cases, one on each side of the vehicle, containing the drive to the centre and rear axles, are designed to rock on the main axle arm up to 30 degrees from horizontal. This permits each rear wheel to rise up to 2 ft. higher than the accompanying wheel on the same side of the chassis.

A new type of interchangeable spring bracket has been developed by Guy Motors, Ltd.. for the Arab under-floorengined passenger chassis. This bracket is made in two parts, which are joined diametrically across the spring-pin hole. In addition to interchangeability, all eight brackets of the front and rear springs being similar, this split bracket eases the task when changing a spring and saves considerable . time.

Although rower-assisted controls were first used in Britain on the Daimler CVD 650 double-decker bus, this was an optional fitting intended as an aid for congested town driving. Power-assisted controls have now been extended to heavy specialized vehicles, such as the Thorny-. croft Might Antar tractor and the Scammell fourand six-wheel-drive chassis, in which all wheels are driven. The 1 hornycroft employs Clayton Dewandrc equipment, the steering effort being assisted hydraulically, whilst the brake and clutch controls have air-pressure gear.

Scammell fourand six-wheel-drive cross.country models incorporate air-pressure braking equipment and, in addition to the normal can and double-roller steering, the drop arm is linked to an external air-pressure arrangement of Clayton

Dewandre pattern. The steering column is divided by a differential, the cage of which operates a reaction valve and admits air to one ot the other side of the servo system attached to the drop arm. The working pressure of the air equipment on these two models is 85-90 lb. per sq. in.

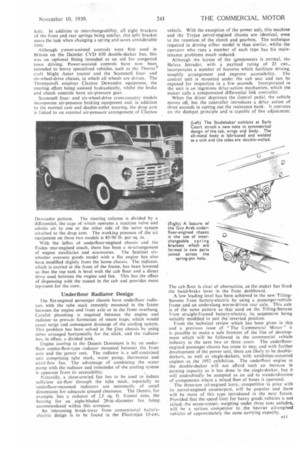

With the influx ot underfloor-engined chassis and the Foden rear-engined coach, there has been a re-arrangement of engine auxiliaries and accessories. The Sentinel siswheeler overseas goods model with a flat engine has also been modified slightly from the home chassis. The radiator, which is carried at the front of the frame, has been lowered so that the top tank is level with the cab floor and a direct drive used between the engine and fan. This has the effect of dispensing with the tunnel in the cab and provides more leg-room for the crew.

Underfloor Radiator Design The flat-engined passenger chassis have underfloor radiators with the tube stack remotely mounted in the frame between the engine and front axle or in the front overhang. Careful plumbing is required between the engine and radiator to prevent formation of steam traps, which would cause surge and consequent drainage of the cooling system. This problem has been solved in the pity chassis by using tubes arranged horizontally for the. stack, and the radiator has, in effect, a divided-tank.

Engine cooling in the Dennis Dominant is by an underfloor contra-flow-type radiator mounted between the front axle and the power unit. The radiator is a self-contained unit comprising tube stack, water pump, thermostat and axial-flow fan. The advantage of combining the water pump with the radiator and remainder of the cooling system is apparent from its accessibility.

Naturally, a close-cowled fan has to be used to induce sufficient air-flow through the tube stack, especially as underfloor-mounted radiators are necessarily of small dimensions for adequate ground clearance. The Dennis, for example, has a radiator of 2t sq. ft frontal arca, the bearing for an eight-bladed 20-in.-diameter fan being accommodated within this compass.

An interesting break-away from conventional batteryelectric design is to be found in the Electrojan 15-cwt.

vehicle, With the exception of the power unit, this machine and the Trojan petrol-engined chassis are identical, even to the retention of the clutch and gearbox. The technique required in driving either model is thus similar, whilst the operator who runs a number of each type has his maintenance problems much reduced.

Although the layout of the Rpmponents is normal. the Helecs intruder, with a payload rating of 25 cwt., incorporates a number of features which facilitate driving, simplify arrangement and improve accessibility. The control unit is mounted under the cab seat and can be exposed for inspection in a few seconds. Incorporated in the unit is an ingenious delay-action mechanism, which the maker calls a compensated differential link controller.

When the driver depresses the control pedal, the vehicle moves off, but the controller introduces a delay action of three seconds in cutting out the resistance bank. It operates on the dashpot principle and is capable of fine adjustment.

The cab floor is clear of obstruction, as the.maker has fitted the hand-brake lever in the front dashboard. • A low loading level has been achieved in the new TillingStevens 5-ton battery-electric by using a passenger-vehicle frame and an underslung worm-driven rear axle. This axle is of the same pattern as that used on the Tilling-Stevens 5-ton straight-framed battery-electric, its suspension being suitably modified to suit the inverted position.

From the technical review which has been given in this and a previous issue of "The Commercial Motor" it• is possible to make a safe forecast of the line of development •which will be followed in the commercial vehicle .industry in the next two or three .years. The underfloorengined passenger chassis has come to stay, and with further development of the power unit, there are likely to be doubledeckers, as well as single-deckers, with amidships-mounted engines at the 1952 exhibition. The underfloor engine in the double-decker will not afford such an increase in earning capacity as it has done in the single-decker, but it will undoubtedly be accepted as an aid to standardization of components where a Mixed fleet of buses is operated. • The three-ton oil-engined lorry, competitive in price with its petrol-engined counterpart, will be popular and there wilr he more of this type introduced in the near future. Provided that the speed. limit for heavy goods .vehicles is not

• raked. the seven-tonner, weighing under three tons unladen, will be a serious competitor to the heavier oil-engined vehicles of approximately the same carrying capacity. al 1