MODULAR BUS SEPARATES PEOPLE FROM POWER PACK

Page 51

Page 52

Page 53

Page 54

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

by Martin Hayes A Duple development for an American contract — described exclusively here the first time — shows outstanding originality for a future bus design

A REVOLUTIONARY bus design using a modular principle which puts passengers and power plant in separate compartments has been developed by the Duple Group. Intended originally for an American Government contract for a new transit bus design, the concept is now being offered to users and manufacturers worldwide.

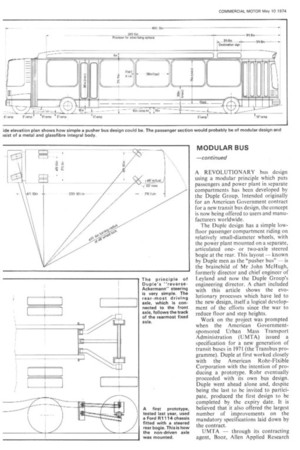

The Duple design has a simple lowfloor passenger compartment riding on relatively small-diameter wheels, with the power plant mounted on a separate, articulated oneor two-axle steered bogie at the rear. This layout — known by Duple men as the "pusher bus" — is the brainchild of Mr John McHugh, formerly director and chief engineer of Leyland and now the Duple Group's engineering director. A chart included with this article shows the evolutionary processes which have led to the new design, itself a logical development of the efforts since the war to reduce floor and step heights.

Work on the project was prompted when the American Governmentsponsored Urban Mass Transport Administration (UMTA) issued a specification for a new generation of transit buses in 1971 (the Transbus programme). Duple at first worked closely with the American Rohr-Flxible Corporation with the intention of producing a prototype. Rohr eventually proceeded with its own bus design. Duple went ahead alone and, despite being the last to be invited to participate, produced the first design to be completed by the expiry date. It is believed that it also offered the largest number of improvements on the mandatory specifications laid down by the contract.

UMTA — through its contracting agent, Booz, Allen Applied Research in discussions on the offer nalysis considered that the Duple esign was very technologically dvanced and professional in its resentation. It had been produced by a 0-man team working round the clock t the premises of Bifort Engineering Id, a Duple subsidiary of which Mr IcHugh is managing director. Some of le most eminent automotive engineers the country were — and still are -ivolved (see Who's Who guide, page 5) At this stage it was discovered that anerican government contract laws ffectively prohibited any foreign 3mpany from benefiting from royalties n a design. Duple had never intended manufacture the vehicle, but to sell its ncept to American builders under ensing agreements. UMTA officials scussed with Duple the possibility of e design being offered voluntarily ithout payment, which was clearly possible for the British company to ept. UMTA eventually awarded art m development contract for three ototypes to Flxible, General Motors d American Motors.

Following this setback, Duple's airman, Frank B. Ford, decided to go ead — at a slower pace with velopment work on the project with • pes of worldwide sales interest. As • IL as the top team of consultants who are still active, the project is now being co-ordinated by a small group at Bifort led by Mr Steve Oxley, the former chief engineer at Atkinson, whose move to Duple Group was exclusively reported in CM in March.

The pusher bus is only one of a number of projects on which Mr Oxley's team is working. Others include: a highfloor single-deck coach very similar to American and European long-distance designs in appearance but using many Dominant components; a 11A-deck: coach with a toilet and cloakroom on the lower level; several low-floor, twinsteer buses of various sizes for precinct and urban work; several double-decker designs; and, for announcement shortly, a self-contained small two-wheeled trailer unit carrying air-conditioning equipment which could simply be plugged in to conventional coach ventilation systems.

But it is the pusher bus which is of most interest to bus operators. Whatever the immediate future holds for the design, its whole concept represents such a major breakthrough in bus technology that it seems certain that many of the ideas it pioneers will play a vital part in public transport developments of the future.

The really significant feature of the pusher bus is the total separation it allows of passengers and power plant. Having accepted this revolutionary idea the advantages it offers seem almost endless. First, and most important, is the removal of the major weight units of the passenger module; the source of noise and pollutants is entirely removed from the passenger environment which itself can be of simple, strong, light

weight construction and, of course, have an ultra-low floor because there is no need to accommodate a driven axle. In the designs submitted to UMTA lightweight passenger compartments riding on two and four air-suspended axles were outlined and double-deck versions of these would be perfectly feasible. The two-axle model has a floor height of 17 in, the four-axle version an incredible 10in. On both models the only intrusion into the flat floor are wheel boxes, which are small enough to fit under normal seats. New low-profile tyres developed by Firestone were used on the UMTA programme to reduce wheel-height still further and oil-cooled multi-disc brakes are specified for installation within the small wheels.

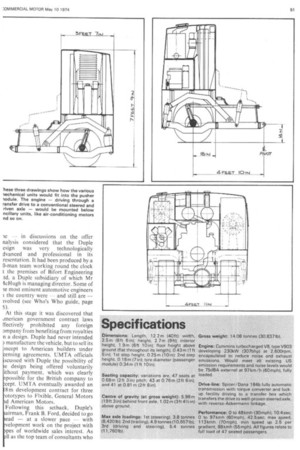

It is the design of the power plant module — essentially a plug-in trailer — that will interest most engineers. It is the connection between it and the passenger compartment which decides the whole viability of the project. Once again the layout of this unit is flexible and oneand two-axle with full-sized wheels and tyres designs have been drawn up. On the single-axle model the axle is both driven and steered, while on the twin-axled bogie version, the rear axle alone performs each function. The ingenious steering system developed by Mr McHugh is described as working on a "reverse-Ackermann principle". As can be seen from the drawing this means that the rear-axle wheels are designed to track with the wheels on the passenger module about a common design centre point.

Power-assisted rack and pinion units on the front passenger axle and rear driven axle are geared together via below-floor linkage which joins both modules.

Not surprisingly it is the design details of the all-important connection between modules which is the most heavily patented area _of the whole vehicle. We have been asked not to reveal for the moment how this particular area is laid out. Suffice it to say that all connections — for steering linkages, electrical components, air-conditioning and, of course, driving force — are rubberbushed to minimize still further noise and vibration in the passenger compartment. Vertical articulation of up to 10 per cent grades is possible with the driving axle. The connections are also quickly detachable, allowing speedy changes of the whole mechanical units package, a process estimated to take only 15 minutes.

This demountable aspect of the power plant means that it could be designed I and built quite separately from the passenger module, but that the two could be depreciated -at different rates, giving potential savings in fleet size and vehicle replacement costs. More efficient maintenance schedules should be possible too. This concept also means that it is easy to develop different types of running units and already there are power-pack designs using battery electrics, hybrid electrics, gas turbines, liquefied natural gas (cryogenically stored), liquefied petroleum gas and even steam engines, in existence.

The American design was fitted with a conventional diesel engine of high output to provide the performance levels essential in US operating conditions. This drives through a fully automatic gearbox and a transfer drive unit to a conventional steered and driven axle. The transmission incorporates a retarder capable of producing 0.1 g deceleration. It is stressed by the designers that most of the mechanical units are of well-proven type but used in a sequence untried before. They have a design life in excess of 500,000 miles.

The power plant module — which is completely encapsulated for high noise absorption — also contains all other ancillary mechanical equipment. As well as a separate engine for airconditioning, this includes fuel tanks, and all pneumatic and electrical systems. Emission control devices are also incorporated. All these units, together with the power plant itself, are readily accessible for maintenance.

The Duple pusher bus project — of which this article can only draw the briefest outline — is a fascinating one. Despite the contractual difficulties in the American situation, work is still going on. Last year a standard Ford RI 114 chassis was fitted with an articulated rear bogie using the reverseAckermann principle for a series of trials, all of which proved successful (see drawing).

This year the building of a full-scale prototype will be started. It is planned that British components will be employed in production though the

prototype steering-engine-transmission package is likely to be European.

Duple Group's intention is — as it has always been — to sell a "technology package" of its concept and not necessarily to produce a complete vehicle. It would be tragic from a technical viewpoint if such an advanced — yet so practical — a British design were allowed to remain undeveloped.