A specialist fork-lift truck haulage business

Page 59

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

THE number and variety of fork-lift trucks used in British industry has mushroomed in recent years. Some of the largest machines such as those specially designed for container handling travel under their own power from the manufacturers to the ports or inland terminals where they will be employed. But a wide range of small and medium capacity trucks are delivered by road from factory to purchaser, either by the manufacturer's own vehicles or by hired transport.

The carriage of fork-lift trucks requires a high degree of expertise at any time but this is particularly true of new machines. Their delivery in immaculate showroom condition is called for.

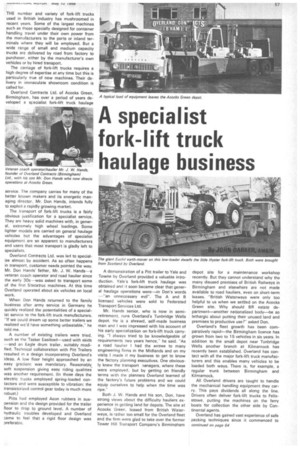

Overland Contracts Ltd. of Acocks Green, Birmingham, has over a period of years developed a specialist fork-lift truck haulage service. The company carries for many of the better known makers and its energetic managing director, Mr. Don Hands, intends fully to exploit a rapidly growing market.

The transport of fork-lift trucks is a fairly obvious justification for a specialist service. They are heavy solid machines with, in general, extremely high wheel loadings. Some lighter models are carried on general haulage vehicles but the advantages of specialist equipment are so apparent to manufacturers and users that most transport is gladly left to specialists.

Overland Contracts Ltd. was led to specialize almost by accident. As so often happens in transport, customer needs pointed the way. Mr. Don Hands' father, Mr. J. W. Hands—a veteran coach operator and road haulier since the early 30s .—was asked to transport some of the first Stacatruc machines. At this time Overland operated about six vehicles on local work.

When Don Hands returned to the family business after army service in Germany he quickly realized the potentialities of a specialist service to the fork-lift truck manufacturers. "If we could dream up some better trailers we realized we'd have something unbeatable," he told me.

A number of existing trailers were tried, such as the Tasker Easiload—used with skids ----and an Eagle drum trailer, suitably modified. Technical collaboration with Pitt Trailers resulted in a design incorporating Overland's ideas. A low floor height approached by an easy gradient was mandatory. Reasonably. soft suspension giving easy riding qualities was another requirement. (In those days the electric trucks employed spring loaded contactors and were susceptible to vibration; the transistorized control gear today is much more robust.)

Pitts had employed Aeon rubbers in suspension and the design provided for the trailer floor to drop to ground level. A number of hydraulic troubles developed and Overland came to feel that a rigid floor design was preferable.

A demonstration of a Pitt trailer to Yale and Towne by Overland provided a valuable introduction. Yale's fork-lift truck haulage was obtained and it soon became -clear that general haulage operations were—in Don's words —"an unnecessary evil". The A and B licensed vehicles were sold to Federated Transport Services Ltd.

Mr. Hands senior, who is now in semiretirement, runs Overland's Tunbridge Wells depot. He is a shrewd, self-made business man and I was impressed with his account of his early specialization on fork-lift truck carrying. "I always tried to be knowledgeable of requirements two years hence," he said. ''As a road haulier I had the entree to many engineering firms in the Midlands and on my visits I made it my business to get to know the factory planning executives. One obviously knew the transport managers, where these were employed, but by getting on friendly terms with the planners Overland learned of the factory's future problems and we could equip ourselves to help when the time was ripe."

Both J. W. Hands and his son, Don, have strong views about the difficulty hauliers experience in getting land for depots. The site at Acocks Green, leased from British Waterways, is rather too small for the Overland fleet and the firm were glad to take over the former Tower Hill Transport Company's Birmingham

.depot site for a maintenance workshop recently. But they cannot understand why the many disused premises of British Railways in Birmingham and elsewhere are not made available to road hauliers, even on short-term leases. "British Waterways were only too helpful to us when we settled on the Acocks Green site. Why should BR estate department—another nationalized body—be so lethargic about putting their unused land and premises to productive use?" asked Don.

Overland's fleet growth has been comparatively rapid—the Birmingham licence has grown from two to 15 vehicles in six years. In addition to the small depot near Tunbridge Wells another branch at Kilmarnock has recently been established. Overland has contact with all the major fork-lift truck manufacturers and this enables many vehicles to be loaded both ways. There is, for example, a regular trunk between Birmingham and Kilmarnock.

All Overland drivers are taught to handle the mechanical handling equipment they carry. This pays dividends all along the line. Drivers often deliver fork-lift trucks to Felixstowe, putting the machines on the ferry boats for collection the other side by Continental agents.

Overland has gained vast experience of safe packing techniques since it commenced to continued on page 64 specialize on the carriage of fork-lift trucks. It is naturally influenced by manufacturers' wishes. Very few manufacturers, it appears, apply a hard-paint finish. Too often, the pressure to deliver a completed truck means that Overland is instructed to make a .delivery before the final finishing coat has had time to harden. Consequently, paint is liable to rub off when a machine is sheeted.

Many types of packing are used to prevent frictional damage with multiple loads. Old Mini tyres are very useful. Straw bags are fine—when they are new. Corrugated paper, too, is satisfactory until it gets rain damaged. Hessian coverings tend to leave an impregnation mark on the paintwork.

Some manufacturers provide heavy polythene or plastics sheet coverings for equipment for which a small additional charge may be made. "One of our customers wanted to fit polythene covers to his equipment at our expense—in the form of a lower haulage rate," Don said. I was not surprised to learn that Overland did not take up this proposal. It might be thought that customers spending £2,000 or more on a fork-lift truck would be tolerant about paying for a protective covering but this is certainly not the position with all customers.

The manufacturers' promotional claims are yet another factor. Some makers of electric trucks stress that their products work in any weather; hence there is no point in covering the machines for transit. Others tell Overland, "keep it dry at all costs". Some makers compromise and supply protective covering for vulnerable parts of the machine.

Fork-lifts come in a great variety of shapes and sizes. Some types are much more easily protected than others. Bridge height limitations sometimes affect routings when trucks with masts as high as 18ft 6in. are carried (the low bridges on the M1 are regretted). Don Hands thinks the best solution may be to fit tilt covers to trailers, with the facility of removing the rear set of hoops and rolling the canvas forward.

It hardly needs to be stressed that the prominent position won by Overland as specialist carriers owes much to the business shrewdness of its management. Fork truck movements are running at about 6,900 a year and the increasing home and export sales of equipment almost certainly will involve considerable expansion.

There is a well-equipped workshop for routine maintenance and minor overhauls. No engine overhauls are done--the great stress is on minimizing down-time and the company prefers to fit replacement units to this end.

The aim is to convert the mixed fleet Dodge, Bedford and AEC vehicles are operated—to 1972 standards.

I was surprised to learn from Don Hands that commercial vehicle maintenance and repairs service in Birmingham is not all it should be. One would have imagined that in a vehicle manufacturing centre a 24-hour service would be the rule and not the exception. Alas, I gather that some garages will not tow in on a 24-hour basis; scarcely tiny firms operate night shifts and vehicles are off the road for much longer than need be. This is particularly unhelpful to firms such as Overland whose "load marrying" is done at Acocks Green; the aim being to use every square inch of the vehicle platform area.

Don Hands is currently Birmingham centre chairman of the Institute of Traffic Administration and he is proud of the centre's 150 membership—the second largest in the country. He feels that road hauliers, in the main, are much too insular. The industry is likely to develop into larger units' in the future, he believes, and this will free more senior executives in road transport to take a wider interest in the problems of transport as a whole.

Although Overland's turnover has increased by 15 per cent in the last two years Don Hands does not pretend that the business has escaped all the rigours of the squeeze. Prior to 1965 all cost increases could be absorbed by increased productivity. Spiralling costs since then have dictated an increasingly more professional attitude to cost accountancy.

Overland expects its costs to increase by 10 per cent if the shorter hours proposal is effected. Double crewing, Don Hands points out, is only possible with fixed points of travel so that it would not solve many of the firm's problems. He does not think there is much scope for additional driver productivity in their type of business.

I was glad to learn that there is a third generation of male Hands—perhaps to provide for continuity of management one day. Don has a six-year-old son. "I am a bit worried" he exclaimed. "The boy cannot tell one type of vehicle from another!"