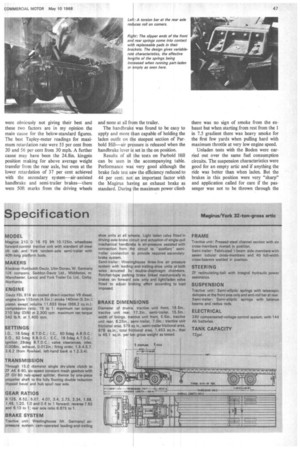

Magirus/York 32-ton gross artic

Page 47

Page 48

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

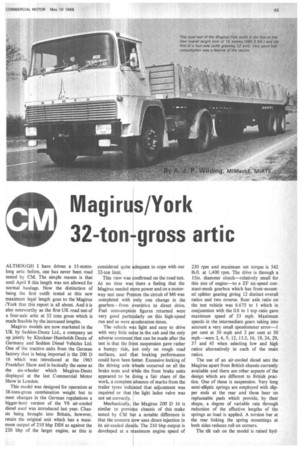

ALTHOUGH I have driven a 15-metrelong artic before, one has never been road tested by CM. The simple reason is that until April 8 this length was not allowed for normal haulage. Now the distinction of being the first outfit tested at this new maximum legal length goes to the Magirus /York that this report is all about. And it is also noteworthy as the first UK road test of a four-axle artic at 32 tons gross which is made feasible by the increased lengths.

Magirus models are now marketed in the UK by Seddon-Deutz Ltd., a company set up jointly by Klockner-Humboldt-Deutz of Germany and Seddon Diesel Vehicles Ltd. One of the tractive units from the German factory that is being imported is the 200 D 16 which was introduced at the 1965 Frankfurt Show and is basically the same as the six-wheeler which Magirus-Deutz displayed at the last Commercial Motor Show in London.

This model was designed for operation at 38-tons-gross combination weight but to meet changes in the German regulations a bigger-bore version of the V8 air-cooled diesel used was introduced last year. Chassis being brought into Britain, however, retain the original unit which has a maximum output of 210 bhp DIN as against the 230 bhp of the larger engine, as this is considered quite adequate to cope with our 32-ton limit.

This view was Confirmed on the road test. At no time was there a feeling that the Magirus needed More power and on a motorway test near PreSton the circuit of M6 was completed with only one change in the gearbox—from overdrive to direct drive. Fuel consumption figures returned were very good particularly on this high-speed run and so were aceleration times.

The vehicle was light and easy to drive with very little noise in the cab and the only adverse comment that can be made after the test is that the front suspension gave rather a bumpy ride, not only on rough road surfaces, and t at braking performance could have been letter. Excessive locking of the driving axle wheels occurred on all the brake tests and While the front brake units appeared to be doing a fair share of the work, a complete absence of marks from the trailer tyres indicated that adjustment was required or that the light laden valve was not set correctly.

Mechanically, the Magirus 200 D 16 is similar to previous chassis of this make tested by CM bin a notable difference is that the concern now uses direct-injection in its air-cooled diesels. The 210 bhp output is developed at a maximum engine speed of

230 rpm and maximum net torque is 542 lb.ft. at 1,400 rpm. The drive is through a 15in. diameter clutch—relatively small for this size of engine—to a ZF six-speed constant-mesh gearbox which has front-mounted splitter gearing giving 12 distinct overall ratios and two reverse. Rear axle ratio on the test vehicle was 6.675 to 1 which in conjunction with the 0.8 to 1 top ratio. gave maximum speed of 53 mph. Maximum speeds in the intermediate gears taking into account a very small speedometer error-1 per cent at 30 mph and 2 per cent at 50 mph—were 2, 6, 9, 12, 13.5, 16, 19, 24, 29, 37 and 45 when selecting low and high ratios alternatively in each of the main ratios.

The use of an air-cooled diesel sets the Magirus apart from British chassis currently available and there are other aspects of the design which are different to British practice. One of these is suspension. Very long semi-elliptic springs are employed with slipper ends at the rear and these bear on replaceable pads which provide, by their shape, a degree of variable rate through reduction of the effective lengths of the springs as load is applied. A torsion bar at the rear linking the spring mountings at both sides reduces roll on corners.

The tilt cab on the model is raised hyd raulically, not to as great an angle as most others available but sufficient for any normal access to the power unit. An access panel in the base pressing of the cab provides for routine oil cheeks.

The semi-trailer used for the test was a York tandem-axle model with 40ft-long platform which at 4 tons 7cwt unladen was relatively light. Coupled to the Magirus which had a kerb weight of 5 tons 6.75ewt allowed a payload of almost 22 tons with the outfit just below the 32-tons limit and two men in the cab brought the weight as tested to a little over the maximum. For unladen tests a Baden 33ft trailer replaced the York and this weighed 3 tons 19.25cwt making the total weight in this condition 9.7 tons.

With the fifth wheel coupling centre line 24.8in. ahead of the rear axle centreline, axle loading worked out to be nearly perfect with slightly extra concentration of weight over the semi-trailer bogie. There were one or two extra concrete blocks over the bogie but to all intents and purposes the load was evenly balanced about the centre of the platform. In the test condition the front and driving axles could each have taken half a ton extra and the semi-trailer bogie nearly a ton extra without exceeding the plated figures. A kingpin position of over 24in. is greater than normal but necessary on the outfit to keep within the 15 metre length limit with a 40ft platform. With a trailer front overhang of 36in. the outfit was only 0.4in. on the safe side of the limit. But the outer-axle spread was 3.4in. short of the 3811 that is the minimum for 32 tons on four axles. This is very little and needed the semi-trailer bogie to be that much nearer the rear end.

Testing took place in the Preston area over routes normally used now on vehicles manufactured in that part of England. Fuel consumption tests over a 16.4 mile out-andreturn circuit north of Broughton gave very good results, the 7.4 mpg returned when cruising at up to 40 mph comparing favourably with results for 30-ton outfits on previous tests even though there was a short stop on the run at traffic lights.

A 19.2 mile high-speed test on M6—outand-return between Bomber Bridge and the 135329—was expected to return about 6.5 mpg in meeting the normal pattern of road tests. But I was surprised to find that there had been only a 0.2 mpg drop from the trunk-road test. On the motorway the outfit was at or near its maximum speed for most of the way and as recorded earlier a change down from overdrive to direct drive was the only gear change called for on the round trip. This was needed on the long gradient approaching the Charnock Richard service area from the north and the speed went down to 30 mph. On the northern leg the minimum speed was 46 mph.

Acceleration tests produced times which have been common on 30 ton outfits and although 10 mph in direct drive represented an engine speed of only 600 rpm—just over idling acceleration times in this ratio were well up to standard. There was slight roughness from the engine at 13 mph (800 rpm) but apart from this the unit pulled away smoothly.

Very long marks were made by the driving axle tyres on the brake tests—between 15 and 20ft from 20 mph and about 50ft from 30 mph on the maximum-pressure service-brake stops. The semi-trailer brakes

were obviously not giving their best and these two factors are in my opinion the main cause for the below-standard figures. The best Tapley-meter readings for maximum retardation rate were 55 per cent fluiii 20 and .56 per cent from 30 mph. A further cause may have been the 24.8in. kingpin position making for above average weight transfer from the rear axle, but even at the lower retardation of 37 per cent achieved with the secondary system—air-assisted handbrake and semi-trailer brakes—there were 50ft marks from the driving wheels

and none at all from the trailer.

The handbrake was found to be easy to apply and more than capable of holding the laden outfit on the steepest section of Parbold Hill—air pressure is released when the handbrake lever is set in the on position.

Results of all the tests on Parbold Hill can be seen in the accompanying table. Performance was very good although the brake fade test SAW the efficiency reduced to 44 per cent; not an important factor with the Magirus having an exhaust brake as standard. During the maximum power climb

there was no sign of smoke from the exhaust but when starting from rest from the 1 in 7.5 gradient there was heavy smoke for the first few yards when pulling hard with maximum throttle at very low engine speed.

Unladen tests with the Boden were carried out over the same fuel consumption circuits. The suspension characteristics were good for an empty artic and if anything the ride was better than when laden. But the brakes in this position were very "sharp" and application called for care if the passenger was not to be thrown through the windscreen—perhaps the light/laden valve was not working properly.

Taken all round the Magirus proved itself an economical vehicle and the driver had his share of benefits also. The steering was very light yet there was no tendency to wander or over-correct even when first taking over the wheel. The brakes had a good "feel", there being good response to movement of the pedal and the clutch was light with adequate hydraulic assistance.

I was not altogether happy with the gear change action in the ZF constant-mesh box. I found it almost impossible to make clean changes on the first day but this turned out to be due largely to incorrect clutch adjustment. When this had been put right it was better but there were still the odd noises when making a change—I am referring to upward changes—from maximum engine speed in the lower gears. Some of this may have been due to varied spacing between the ratios in the main box and an unusually quick dying down of the engine. Gear changing may also have become more easy with more experience of the box as I only had a couple of hours with the clutch at the correct setting.

Controls well placed

Most controls were well placed but the gear change knob was farther than normal from the driver. This, added to the fact that the gear positions are reversed with the low gears on the driver's side of the "gate", meant that the most frequent changes between top and fifth called for the most stretching—and it was a good stretch, too.

Visibility from the driver's seat was very good and the standard mirrors gave an excellent view to the rear. Access to the cab is through two forward-mounted steps up to the floor and there are well-placed grab handles for both the driver and passenger. Interior of the cab is well finished and seats are comfortable.

The hydraulic-pump mechanism to tilt the cab takes all the effort out of this job and eliminates torsion bar linkages. Although a relatively small degree of tilt is given, there is full access to the engine and its accessories.

As tested, the Magirus 210 D 16 FS has a list price of £4,795, inclusive of a number of items such as power steering, 12-speed gearbox, twin fuel tanks and heater which are often extra-cost options on this class of vehicle. The York 40ft SL 32 platform semi-trailer for the test as fitted out with light/laden valve, 10.00-20 tyres etc., had a price tag of 11,634.