Overhauling 18 Buses at a Time

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

SPACIOUSNESS and comprehensive equipment are the keynotes of the new central workshops at New Writtle Street, Chelmsford, of the Eastern National Omnibus Co., Ltd. As announced in The Commercial Motor, they were opened last Friday by Mr. W. P. S. Ormond, chairman of the Eastern Traffic Commissioners.

Eastern National's fleet is made up of son-le 700 buses and coaches, and all major repairs and overhauls will be carried out at the new premises. The vehicles operate on a wide variety of stage services, covering a territory extending from the I.ondon area through Essex and parts of Hertford

n8 shire to Ipswich. Places as far north as Lowestoft and Yarmouth arc served by express services, which arc also run between East Anglia and certain southcoast resorts.

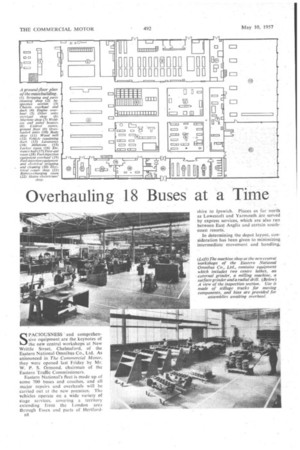

In determining the depot layout, consideration has been given to minimizing intermediate movement and handling, (Left)The machine shop at the new central workshops of the Eastern National Omnibus Co., Ltd., contains equipment which includes Iwo centre lathes, an external grinder, a milling machine, a surface grinder and a radial drill. (Below) A view of the inspection section. Use is made of stillage trucks for moving components, and bins are provided for assemblies awaiting overhaul. whilst there is room for 18 vehicles under heavy repair at any time, either singleor double-deckers. The staff will number 150, and special attention has been paid to the provision of adequate amenities.

Covering an area of 46,000 sq. ft., the new building is of steel-frame construction clad with brick and asbestos. Also of asbestos, the roof is lined with overpurlin insulation board.

Annexed to the main building is the stripping, cleaning and inspection department. Here a unit for overhaul is steam cleaned externally, stripped, degreased and passed to the inspection section where the parts are examined, passed as fit, sent to the machine shop for reconditioning, or scrapped. Where necessary, replacement parts are drawn from the new or reconditioned stores on a combined requisition, the assembly then being placed in a bin ready for transfer to the appropriate overhaul shop when required.

Dismantled parts of vehicles undergoing dock overhaul are also catered for by this department, which handles all material rejected from docking shops and depots as well. An electric hoist on a wheeled overhead gantry facilitates the lifting of units and materials.

At prescribed mileages and after Steam cleaning, vehicles are brought in for a complete mechanical overhaul or docking in accordance with a prearranged programme. This is based on routine inspection, and adjustment every 5,000 miles at depots, docking at 50,000-mile intervals, and unit change or major overhaul after 150,000 miles or more.

A noteworthy feature of the part of the building where this work is carried out is the method of pit construction.

The whole area is sunken, the suspended floor between the pits being supported on reinforced concrete pillars. Individual pits, or the whole area, may be guarded by means of sunken tubular posts with chains attached and contained in them. Space below the floor is used for stowing gear.

An exhaust duct is provided with a branch for each pit, ensuring that exhaust fumes are taken direct to the outside atmosphere.

Engine overhaul is in two parts. Crankcase overhaul, comprising line boring, fitting the crankshaft and connecting rods, pistons and cylinder blocks, is followed by general assembly and timing of the engine. Geared pulley blocks on an overhead runway are used to move engines within the shop.

Engine sub-assemblies, which include water pumps, cylinder heads and blocks, are also dealt with in this section. They are supplied through the stores to meet the needs of docking shops and depots. Machine tools peculiar to engine overhaul have been installed in the section for convenience.

As its name suggests, the "other units overhaul shop" deals with all mechanical assemblies apart from engines. Stands are provided for the units, and equipment includes a servo test rig, manual press, honing machine and tackle for lifting and moving heavy components.

Apart from the usual, the tools in the machine shop include two centre lathes of different capacities, an external grinder, a milling machine, a surface grinder and a radial drill.

Seven vehicles can be accommodated in the body shop, which has the paint shop adjacent to it, but separated by a wall and glazed screen to roof level. Vehicles are repainted by brushing, there being space for five.

A room is set aside for the overhaul of fuel-injection equipment, and a small cleaning shop which is shared interconnects with the vehicle electrical equipment section of the electrical overhaul department.

Offices Above

Although most of the main building is at ground-floor level, an upper floor houses the offices, canteen, part of the stores and the trimmers' shop. The central stores supplies the workshops as well as docking shops and depots. On the ground floor it is laid out with bins for vehicle and body parts, whilst the top floor is subdivided for the storage of uniforms and stationery, and separately for the more bulky general vehicle stores.

This material is lifted to _the upper floor by., means of an outside electric hoist, and is passed through a door on that floor. Units requiring overhaul, reconditioned road springs, empty drums, cases and so on, timber and scrap material arc kept in an outbuilding.

The engine test house forms part of a separate building. It provides for the brake-testing of overhauled engines and .any experimental engine work that may be undertaken.