A French Fuel Pump

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

with Original Features

Radially Disposed Cylinders and Plungers Operated by a Face Cam

THE BeHem is a new fuel pump with

certain original features. It has been brought out in France after more than four years of study and experiment and is made by Messrs. Bellem and Foss, 5, Rue du Lieut. Boncour, Neuilly.

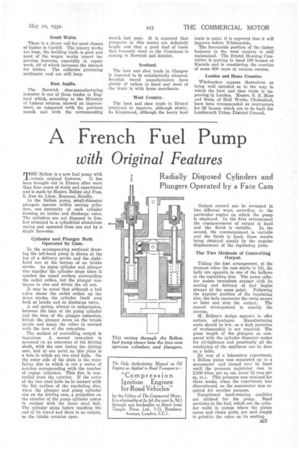

In the Bellem pump, small-diameter plungers operate within moving cylinders, one extremity of each cylinder forming an intake and discharge valve. The cylinders are not disposed in line, but arranged in a cylindrical aluminium casing and operated from one end by a single face-cam.

Cylinder and Plunger Both Operated by Cam.

In the accompanying sectional drawing the left-hand pump is shown at the top of a delivery stroke and the righthand one at the bottom of an intake stroke. As pump cylinder and plunger rise together the cylinder stops when it reaches the coned surface surrounding the outlet orifice, but the plunger continues to rise and drives the oil out.

It may be noted that although a ball valve closes the outlet orifice on the down stroke, the cylinder itself acts both as intake and as discharge valve.

A coil spring, always in compression, between the base of the pump cylinder and the base of the plunger extension, brings the plunger down on the intake stroke and keeps the roller in contact with the face of the cam-plate.

The method of controlling output is ingenious. A second cam-plate is mounted on an extension of the driving shaft, with the cam facing the driving cam, and at one point on this plate is a hole in which are two steel balls. On the outer side of the plate is the regulating disc in which is cut a series of notches corresponding with the number of engine cylinders. This disc is controlled from the exterior. If the outer of the two steel balls be in contact with the fiat surface of the regulating disc, when the plunger and pump cylinder rise on the driving cam, a projection on the exterior of the pump cylinder comes in contact with the inner steel ball. The cylinder stops before reaching the end of its travel and there is no output, as the intake remains open. Output control • can be arranged in two different ways, according to the particular engine on which the pump is employed. In the first arrangement the commencement of output is fixed and the finish is variable. In the second, the commencement is variable and the finish is fixed, these results being obtained simply by the angular displacement of the regulating plate.

The Two Methods of Controlling

Taking the fist arrangement, at the moment when the cam starts to lift, the balls are opposite to one of the hollows in the regulating disc. The pump cylinder makes immediate contact with its seating and delivery of fuel begins always at the same point. Following the angular position of the regulating disc, the halls encounter the ramp sooner or later and stop the output. The second arrangement is exactly the reverse.

M. Bellein's design appears to offer certain advantages. Manufacturing costs should be low, as a high precision of workmanship is not required. The great length of the plungers as compared with the cylinder diameter makes for oil-tightness and practically all the machining of the appliance can be done on a lathe.

By way of a laboratory experiment, a Bellem pump was connected up to a manometer and turned over by hand until the pressure registered rose to 2,000 kilos. per sq. cm. (over 12 tons per sq. in.). This pressure was retained for three weeks' when the experiment was discontinued, as the manometer was required for another purpose.

Exceptional hard-wearing qualities are claimed for the pump. Sand particles in the fuel, which cut the cylin.der walls in pumps where the piston opens and closes ports, are said simply to grind-in the valve on its seating. B27