An Analysis of Coi ler Braking Systems

Page 70

Page 71

Page 72

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

THE growth of cross-Channel and transcontinental haulage in recent years has not been without its

problems. Developments in the use of containers and demountable bodies have been of great assistance to operatars in this field, but the ready interchangeability of tractors and trailers has been hampered by the number of different braking systems fitted to these vehicles.

There are standards for dimensions of semi-trailer couplings and for dimensions of towing hooks, but, because there is more than one standard in each case, it is not always certain that a particular trailer or semi-trailer can be coupled to a particular prime mover. It is even less certain—in fact, extremely unlikely—that the braking system of the trailer will match with that of the prime mover.

Hydraulic braking does not really have any part in the problem because, in this case, either trailer braking is by direct mechanical linkage or an air-pressure or vacuum system is added to the tractor layout to supply the requirements of the particular trailer. The coupling of trailers to prime movers which have air-pressure or vacuum-operated brakes, or such systems added to them for trailer operation, is therefore the field.for standardization.

Current Systems

What is the present position? The manufacture of airpressure or vacuum braking equipment in this country is confined in the main to three concerns: Clayton Dewandre Co.. Ltd., Lincoln; Westinghouse Brake and Signal Co., Ltd., Kingswood, Bristol, who make only air-pressure equipment; and Feeny and Johnson, Ltd., Wembley, who specialize in the manufacture of vacuum equipment and the fitting of complete systems to vehicles, either to increase the effort at the trailer brakes or as a modification to a vehicle not originally built as a tractor or tractive unit. Clayton Dewandre or Westinghouse supply the original equipment for the majority of power-braked commercial vehicles of British manufacture.

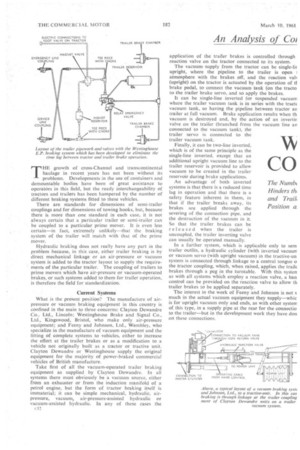

Take first of all the vacuum-operated trailer braking equipment as supplied by Clayton Dewandre. In all systems there must obviously be a vacuum source, either from an exhauster or from the induction manifold of a petrol engine, but the form of tractor braking itself is immaterial; it can be simple mechanical, hydraulic, airpressure, vacuum, air-pressure-assisted hydraulic or vacuum-assisted hydraulic. In any of these cases the cr application of the trailer brakes is controlled through reaction valve on the tractor connected to its system.

The vacuumsupply from the tractor can be single-lit upright, where the pipeline to the trailer is open I atmosphere with the brakes off, and the reaction vall (upright) on the tractor is actuated by the operation of tl brake pedal, to connect the vacuum tank (on the tract° to the trailer brake servo, and so apply the brakes.

It can be single-line inverted (or suspended vacuum where the trailer vacuum tank is in series with the tract( vacuum tank, so having the pipeline between tractor an trailer at full vacuum. Brake application results when th vacuum is destroyed and, by the action of an invertin valve on the trailer (branched from the vacuum line an connected to the vacuum tank), the trailer servo is connected to the trailer vacuum tank.

Finally, it can be two-line inverted, which is of the same principle as the single-line inverted, except that an additional upright vacuum line to the trailer reservoir is provided to allow vacuum to be created in the trailer reservoir during brake applications.

An advantage of both inverted systems is that there is a reduced time lag in operation and that there is a safety feature inherent in them, in that if the trailer breaks away, its brakes are applied through the severing of the connection pipe. and the destruction of the vacuum in it.

So that the trailer brakes can be released when the trailer is uncoupled, the trailer inverting valve can usually be operated manually.

In a further system, which is applicable only to sem trailer outfits, a hydraulic cylinder (with inverted vacuurr or vacuum servo (with upright vacuum) in the tractive-un system is connected through linkage to a central tongue o the tractor coupling, which, when raised, applies the traile brakes through a peg in the turntable. With this systen as with all systems which employ a reaction valve, a ban control can be provided on the reaction valve to allow th trailer brakes to be applied separately.

The interest in the work of Feeny and Johnson is not s much in the actual vacuum equipment they supply—whic is for upright vacuum only and ends, as with other system of this type, in a supply pipe at the rear for the connectio to the trailer—but in the development work they have don on these connections.

CO

The Numb( Hinders th and Trail( Position a,

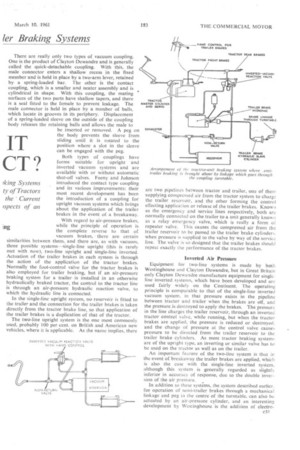

There are really only two types of vacuum coupling. One is the product of Clayton Dewandre and is generally called the quick-detachable coupling. With this, the male connector enters a shallow recess in the fixed member and is held in place by a two-arm lever, retained by a spring-loaded bar. The other is the contact coupling, which is a smaller and neater assembly and is cylindrical in shape. With this coupling, the mating

surfaces of the two parts have shallow tapers, and there TRACTOR- is a seal fitted to the female to prevent leakage. The mAsATNT

IT

male connector is held in place by a number of balls, which locate in grooves in its periphery. Displacement of a spring-loaded sleeve on the outside of the coupling body releases the retaining balls and allows the male to be inserted or removed. A peg on the body prevents the sleeve from sliding until it is rotated to the position where a slot in the sleeve can be engaged with the peg.

Both types of couplings have forms suitable for upright and inverted vacuum systems and are available with or without automatic shut-off valves. Feeny and Johnson introduced the contact type coupling and its various improvements: their most recent development has been the introduction of a coupling for upright vacuum systems which brings about the application of the trailer brakes in the event of a breakaway.

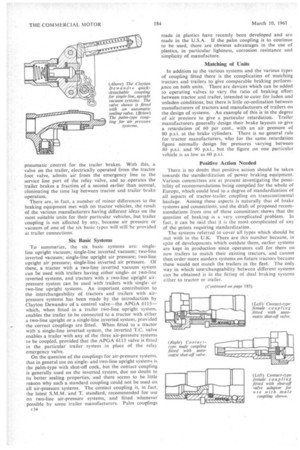

With regard to air-pressure brakes, while the principle of operation is the complete reverse to that of vacuum brakes, there are certain similarities between them, and there are, as with vacuum, three possible systems—single-line upright (this is rarely met with now), two-line upright and single-line inverted. Actuation of the trailer brakes in each system is through the action of the application of the tractor brakes. Normally the foot-control valve for the tractor brakes is also employed for trailer braking, but if an air-pressure braking system for a trailer is installed in an otherwise hydraulically braked tractor, the control to the tractor line is through an air-pressure hydraulic reaction valve, to which the hydraulic line is connected.

In the single-line upright system, no reservoir is fitted to the trailer and the connection for the trailer brakes is taken directly from the tractor brake line, so that application of the trailer brakes is a duplication of that of the tractor.

The two-line upright system is the one most commonly used, probably 100 per cent. on British and American new vehicles, where it is applicable. As the name implies. there are two pipelines between tractor and trailer, one of them supplying compressed air from the tractor system to charge the trailer reservoir, and the other forming the control effecting application or release of the trailer brakes. Known as the emergency and service lines respectively, both are normally connected on the trailer to a unit generally known as a relay emergency valve, which is really a form of repeater valve. This causes the compressed air from the trailer reservoir to be passed to the trailer brake cylinders. when pressure is supplied to the valve by way of the serviec line. The valve is so designed that the trailer brakes should repeat exactly the performance of the tractor brakes.

Inverted Air Pressure

Equipment for two-line systems is made by both Westinghouse and Clayton Dewandre, but in Great Britain only Clayton Dewandre manufacture equipment for singleline inverted systems, which have been developed and are used fairly widely on the Continent. The operating principle is comparable to that of the single-line inverted vacuum system. in that pressure exists in the pipeline between tractor and trailer when the brakes are off, and the pressure is destroyed to apply the brakes. The pressure in the line charges the trailer reservoir, through an inverted tractor control valve, while running, but when the tractor brakes are applied, the pressure is reduced or destroyed. and the change of pressure at the control valve causes pressure to be directed from the trailer reservoir to the trailer brake cylinders. As most tractor braking systems are of the upright type, an inverting or similar valve has to be used on the tractor as well as on the trailer.

An important feature of the two-line system is that in the event of breakaway the trailer brakes are applied, which is also the case with the single-line inverted system. although this system is generally regarded as slightly inferior in accuracy of response, due to the double inversion of the air pressure.

In addition to these systems, the system described earlier. for operation of semi-trailer brakes through a mechanical linkage and peg in the centre of the turntable, can also be actuated by an air-pressure cylinder, and an interesting development by Westinghouse is the addition of electro pneumatic .control for the trailer brakes. With this, a valve on the trailer, electrically operated from the tractor foot valve, admits air from the emergency line to the service line port of the relay valve, and so operates the trailer brakes a fraction of a second earlier than normal, eliminating the time lag between tractor and trailer brake operation.

There are, in fact, a number of minor differences to the braking equipment met with on tractor vehicles, the result of the various manufacturers having different ideas on the most suitable units for their particular vehicles, but trailer coupling is not affected by any, because air pressure or vacuum of one of the six basic types will still be provided at trailer connections.

Six Basic Systems To summarize, the six basic systems are: singleline upright vacuum; single-line inverted vacuum; two-line inverted vacuum; single-line upright air pressure; two-line upright air pressure; single-line inverted air pressure. Of these, a tractor with a two-line inverted vacuum system can be used with trailers having either singleor two-line inverted systems, and tractors with a two-line upright airpressure system can be used with trailers with singleor two-line upright systems. An important contribution to the interchangeability of tractors and trailers with airpressure systems has been made by the introduction by Clayton Dewandre of a control valve—the APGA 6113— which, when fitted in a trailer two-line upright system, enables the trailer to be connected to a tractor with either a two-line upright or a single-line inverted system, provided the correct couplings are fitted. When fitted to a tractor with a single-line inverted system, the inverted T.C..valve enables a trailer with any of the three air-pressure systems to be coupled, provided that the APGA 6113 valve is fitted in the particular trailer system in place of the relay emergency valve.

On the question of the couplings for air-pressure systems, that in general use on singleand two-line upright systems is the palm-type with shut-off cock, but the contact coupling is generally used on the inverted system, due no doubt to its better sealing properties, and there seems to be little reason why such a standard coupling could not be used on all air-pressure systems. The contact coupling is, in fact, the latest S.M.M. and T. standard, recommended for use on two-line air-pressure systems, and fitted whenever possible by some trailer manufacturers. Palm couplings c34 made in plastics have recently been developed and are made in the U.S.A. If the palm coupling is to continue to be used, there are obvious advantages in the use of plastics, in particular lightness, corrosion resistance and simplicity of manufacture.

Matching of Units

In addition to the various systems and the various types of coupling fitted there is the complication of matching tractors and trailers to give comparable braking perform„ance on both units. There are devices which can be added to operating valves to vary the ratio of braking effort between tractor and trailer, intended to cater for laden and unladen conditions, but there is little co-ordination between manufacturers of tractors and manufacturers of trailers on the design of systems. An example of this is in the degree of air pressure to give a particular retardation. Trailer manufacturers generally design their brake layouts to give a retardation of 60 per cent., with an air pressure of 80 p.s.i. at the brake cylinders. There is no general rule for tractor manufacturers, who for the same retardation figure normally design for pressures varying between 80 p.s.i. and 90 p.s.i., but the figure on one particular vehicle is as low as 60 p.s.i.

Positive Action Needed

There is no doubt that positive action should be taken towards the standardization of power braking equipment. Various committees are at present investigating the possibility of recommendations being compiled for the whole of Europe, which could lead to a degree of standardization of all aspects of tractor-trailer coupling on transcontinental haulage. Among these aspects is naturally that of brake systems and connections, and the draft of proposed recommendations from one of these committees shows that the question of braking is a very complicated problem. In fact, it can be said that it is the most complicated of any of the points requiring standardization.

The systems referred to cover all types which should be met with in the U.K. There are this number because, in spite of developments which outdate them, earlier systems are kept in production since operators call for them on new trailers to match their existing tractors, and cannot then order more modern systems on future tractors because these would not match the trailers in the fleet. The only way in which interchangeability between different systems can be obtained is in the fitting of dual braking systems either to tractor or trailer. It would be easier and more economical to make the trailer the unit with the dual System. It would also be a sensible move towards standardization because if, for example, all new trailers built with vacuum or single-line upright or inverted air-pressure systems were fitted also with a two-line air-pressure system, eventually all trailers on the road could be coupled with a tractor with a two-line air-pressure system. It could be 20 years or more before this ideal would be arrived at, but at ,least there would be the prospect of eventual standardization.

At the moment there is no such prospect and all the discussions on such problems take so long, admittedly not . . without reason, that it could be many years before even a start is made to improve the poSition. Agreement on a standardized system is made difficult by the general attitude of members of all international committees formed to investigate such problems. Usually, all agree that standardization is necessary, but all want their own particular national system to be the one adopted as the standard.

Unless there is a change in this attitude and all aspects of.. tractor/trailer coupling are considered purely on their technical merits, without national bias, there is little chance of an improvement in the position in the foreseeable future.