2,150 Tons a Week—

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

in one vehicle

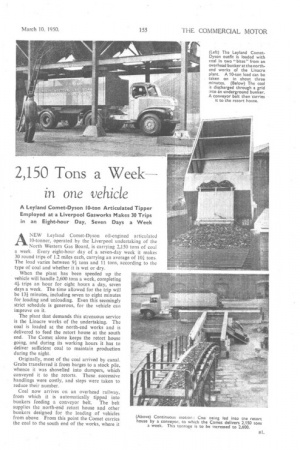

A Leyland Comet-Dyson 10-ton Articulated Tipper Employed at a Liverpool Gasworks Makes 30 Trips in an Eight-hour Day, Seven Days a Week

ANEW Leyland Cornet-Dyson oil-engined articulated 10-tonner, operated by the Liverpool undertaking of the North Western Gas Board, is carrying 2,150 tons of coal a week Every eight-hour day of a seven-day week it makes 30 round trips of 1.2 miles each, carrying an average of 10.1 tons The load varies between 9} tons and 11 tons, according to the type of coal and whether it is wet or dry.

When the plant has been speeded up the vehicle will handle 2,600 tons a week, completing C-. trips an hour for eight hours a day, seven days a week. The time allowed for the trip will be 13iminutes, including seven to eight minutes for loading and unloading. Even this seemingly strict schedule is generous, for the vehicle can improve on it.

The plant that demands this strenuous service is the Linacre works of the undertaking. The coal is loaded at the north-end works and is delivered to feed the retort house at the south end. The Comet alone keeps the retort house going, and during its working hours it has to deliver sufficient coal to maintain production during the night.

Originally, most of the coal arrived by canal. Grabs transferred it from barges to a stack pile, whence it was shovelled into dumpers, which conveyed it to the retorts. These, successive handlings were costly, and steps were taken to reduce their number.

Coal now arrives on an overhead railway, from which it is automatically tipped into bunkers feeding a conveyor belt. The belt supplies the north-end retort house and other bunkers designed for the loading of vehicles from above From this point the Cornet carries the coal to the south end of the works, where it runs on to a grid and tips its load into a bunker, from which a conveyor belt feeds the retort house.

Formerly, 6-7-ton vehicles were hired to carry the coal at a cost of 6d.-6d. a ton. The Comet does the work at 4id. a ton. At this rate, its capital cost will be recovered in about two years, although the vehicle is being depreciated over 12 years. When the modernization programme has been completed and the capacity of the conveyor belts has been increased to equal the Leyland's appetite for work, it is hoped to reduce the cost to 31-d. a ton.

"Artic,. " for Economy

Transport by means of overhead buckets was considered, but was rejected as too costly. The choice of a mechanical-handling system narrowed down to a vehicle or vehicles, and an articulated unit was selected because of the need for a high degree of manceuvrability at the unloading point.

Mr. H. R. Hextall, the transport manager, is well satisfied with the experiment. Despite the great amount of tipping and the short lead, the fuel-consumption rate of the Comet is 8.3 m.p.g.

The chassis and body of the semitrailer, built by R. A. Dyson and Co.,

Ltd., 76-80, Grafton Street, Liverpool, 8, are of all-steel welded construction. The body, which has a capacity of 425 cubic ft., has an overall length of 16 ft. 8 ins., a width of 7 ft. and a height of 4 ft. It can be tipped to an angle of 50 degrees by Edbro gear. Clayton Dewandre vacuum servo brakes are fitted. The complete outfit weighs 7 tons 2 cwt. unladen.

Although the Comet is the only oil-engined unit in a fleet of 56 light commercial vehicles and 35 cars, it is by no means a cuckoo in the maintenance department's nest. The department is well accustomed to maintaining oil engines in compresgors and other mobile units, and will do most of the work on the Leyland engine.

Mileages at which maintenance work is carried out vary according to the type of vehicle and the work upon which it is engaged, but, as a rule, a vehicle receives five major

docks during its lifetime. Intermediate attention is based on a weekly report by drivers and a monthly inspection made, without notice to the driver, by a chargehand.

Light vehicles deliver coke and gas appliances in the area of 110 sq. miles in which gas is distributed. As part of the transport control system, frequent checks are made on the cost of delivery of the various items.

The records are amplified by charts showing the amounts delivered and the cost of delivery, separately, of coke in bags, coke in, bulk, coke in bulk-bags (to schools and other consumers who require bulk deliveries in bags), and appliances.

A Servis recorder is fitted to each vehicle. The recorder card is checked every morning, and an explanation of every delay is written on it. The card on the Comet shows an almost continuous line.

Bonus on Mileage

A safe-driving bonus scheme, based on mileage has been found to reduce accidents. At one time a bonus of £5 was paid for five years' freedom from blameworthy accident. This system favoured the drivers of low-mileage vehicles, it was thought, whereas a bonus based on accidentfree mileage would take into account the greater number of risks safely avoided by drivers covering long distances during the period.

A bonus of £2 15s. is now paid for the completion, without accident, of every 10,000 miles.. During 1944 44 payments were made and one driver gained the award four times.