A Micrometer-adjusted Floating Reamer

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

the ordinary way a reamer finish cannot be relied upon

to produce a bore' that is completely free ,from chatter marks, although a casual inspection might be deceiving in this respect. Reaming troubles, however, would appear to have been satisfactorily solved by a new floating-type tool, recently introduced by David Brown and Sons (Huddersfield), Ltd., Huddersfield,

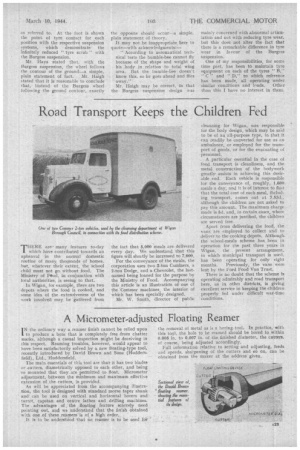

The main essentials of this tool are that it has two blades or cutters, diametrically opposed to each other, and being so mounted that they are permitted to float. Micrometer adjustment, between the minimum and maximum effective extension of the cutters, is provided.

As will be appreciated from the accompanying illustrafion, the tool is designed with standard morse taper shank and can be used on vertical and horizontal borers and turret, capstan and centre lathes and drilling machines. The advantages .of the floating feature scarcely need pointing out, and we understand that the finish obtained with one of these.reamers is of a high order.

It is to be understood that no reamer is to be used Icir

the removal of metal as is.a haring. tool. In practice,with this tool, the hole to be reamed should be bored tO within 0.005 in. to 0.007 iii. of the finished diaineter, the cutters, of course, being adjusted 'accordingly.

Full information relative to setting and adjusting, feeds and speeds, sharpening of the cutters and so on, can be obtained from the maker at the address given.