Two Stroke or Four Stroke?

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

An Acknowledged Authority Analyses the Facts and Gives theTechnicalReasons Why the Apparent Advantage of the Two-stroke Cycle for Vehicle Engines is Unreal

By C. W. Chapman, M.Eng.

IN this country, the four-stroke engine is almost unchallenged for road-vehicle propulsion. In America, the two-stroke engine is now putting up a challenge in this field. It might appear that the twostroke engine should completely oust the four-stroke, because with a firing stroke every revolution it should theoretically develop, from a given cylinder size, twice the power output of a four-stroke engine.

It is proposed to examine briefly this theoretical advantage from a practical aspect, taking one of the most popular types of four-stroke oil engine and comparing it with the latest development in the two-stroke field, relative to the employment of the compression-ignition system.

Two-stroke Valve Systems.

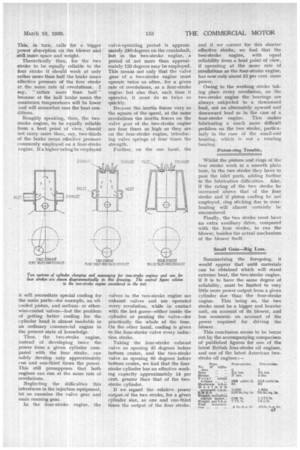

In the two-stroke oil engine, air may be introduced and the exhaust discharged through corresponding ports on opposite sides near the bottom of the working cylinder, but this does not lead to very effective scavenge. The latest two-stroke engine is provided with inlet ports at the bottom of the working cylinder and exhaust valves in the cylinder head, and this is the type which it is proposed to compare with the fourstroke engine. Supercharging in each case will be excluded.

The orthodox four-stroke engine has one inlet valve and one exhaust

valve per cylinder. On the first down stroke air is drawn in through the inlet valve ; on the up stroke the BO air is compressed ; then on the second revolution burning and expansion take place on the down stroke whilst on the up stroke the exhaust gases are pushed out through the exhaust valve.

In the two-stroke engine there are no suction or exhaust strokes to draw in or force out the gases, there being merely the compression and the burning and expansion strokes. Accordingly this engine must have some external means to blow the air into the cylinder. In modern engines this takes the form of a mechanical displacement-type blower driven by the engine. This blower must displace rather more than the swept volume of the cylinder to give effective scavenge.

We thus see that, for the twostroke engine to give theoretically twice the output of a four-stroke engine, the former must be heavier than the latter by the weight of the blower. It should be noted, however, that the blower can be more compact, for a given swept volume, and appreciably lighter, than working cylinders of the same effective volume. So far, therefore, there is a distinct advantage to the two-stroke engine.

Being able to produce a certain amount of power from a given cylinder size is not the whole story, for the well-designed compressionignition four-stroke engine can develop brake mean effective pressures with good combustion up to and even in excess of 120 lb. per sq. in., but corresponding powers cannot be used commercially because of the heat conditions on the cylinder head, piston, and exhaust valves. The brake mean effective pressure of the four-stroke engine for commercialroad-vehicle use is usually limited to approximately 100 lb. per sq. in., purely on account of the difficulty of dissipating the heat in a simple commercial engine.

For the two-stroke engine to develop twice the power from a given cylinder size compared with the fourstroke engine it must work at the same rate of revolutions, and with the same brake mean effective pressures and must therefore dissipate twice the amount of heat of the four-stroke engine.

Heat-dissipation Difficulty.

As experience with the four-stroke engine has shown that it is not commercially practicable to dissipate even the full heat which can be developedfrom a four-stroke engine, it is clear that if an attempt be made to dissipate from a two-stroke unit twice the amount of heat, it must definitely be working under commercially dangerous conditions. Moreover, in the four-stroke engine, there is a definite cooling stroke every other revolution when cold air is drawn into the cylinder • and maintained therein for an appreciable period, whilst no such cooling stroke takes place in the two-stroke engine unless a bigger blower passing through excess scavenge air be used.

This, in turn, calls for a bigger power absorption on the blower and still more space and weight.

Theoretically then, for the two stroke to be equally reliable to the four stroke it should work at only rather more than half the brake mean effective pressure of the four stroke at the same rate of revolutions. I say, "rather more than halt" because at the half brake mean the maximum temperatures will be lower and will somewhat ease the heat conditions.

Roughly speaking, then, the twostroke engine, to be equally reliable from a heat point of view, should not carry more than, say, two-thirds of the brake mean effective pressure commonly employed on a four-stroke engine. If a higher rating be employed it will necessitate special cooling for the main parts—for example, an oilcooled piston, and sodiumor otherwise-cooled valves—but the problem of getting better cooling for the cylinder head is almost insoluble in an ordinary commercial engine in the present state of knowledge.

Thus, the two-stroke engine, instead of developing twice the power from a given cylinder compared with the four stroke, can safely develop only approximately one and one-third times the power. This still presupposes that both engines can run at the same rate of revolutions.

Neglecting the difficulties this introduces in the injection equipment, let us examine the valve gear and main running gear.

In the four-stroke engine, the valve-operating period is approximately 240 degrees on the crankshaft, but in the two-stroke engine, a period of not more than approximately 120 degrees may be employed. This means not only that the valve gear of a two-stroke engine must operate twice as often, for a given rate of revolutions, as a four-stroke engine but also that, each time it operates, it must do so twice as quickly.

Because the, inertia forces vary as the square of the speed, at the same revolutions the inertia forces on the valve gear of the two-stroke engine are four times as high •as they are on the four-stroke engine, introducing valve springs of four times the strength.

Further, on the one hand, the valves in the two-stroke engine are exhaust valves and are operated every revolution, while in contact with the hot gases—either inside the cylinder or passing the valve—for practically the whole of the time. On the other hand, cooling is given to the four-stroke valve every induction stroke.

Taking the four-stroke exhaust valve as opening 45 degrees before bottom centre, and the two-stroke valve as opening 430 degrees before bottom centre, we find that the fourstroke cylinder has an effective working capacity approximately 14 per cent, greater than that of the twostroke cylinder.

If we regard the relative• power output of the two stroke, for a given cylinder size, as one and one-third times the output of the four stroke. and if we correct for this shorter effective stroke, we find that the two-stroke engine, with equal reliability from a heat point of view, if operating at the same rate of revolutions as the four-stroke engine, has now only about 15 per cent. more power.

Owing to the working stroke taking place every revolution, on the two-stroke engine the bearings are always subjected to a downward load, not an alternately upward and downward load as in the case of a four-stroke engine. This makes lubricating a much more difficult problem on the two stroke, particularly in the case of the small-end bearing, which is not a rotating bearing.

Piston-ring Trouble.

Whilst the pistons and rings of the four stroke work in a smooth plain bore, in the two stroke they have to pass the inlet ports, adding further to the lubrication difficulties. Also, if the rating of the two stroke be increased above that of the four stroke and if piston cooling be not employed, ring sticking due to overheating will almost • certainly be encountered.

Finally, the two stroke must have an extra auxiliary drive, compared with the four stroke, to run the blower, besides the actual mechanism of the blower itself.

Small Gain—Big Loss.

Summarizing the foregoing, it would appear that until materials can be obtained which will stand extreme heat, the two-stroke engine, if it is to have the same degree of reliability, must be limited to very. little more power output from a given cylinder size than the four-stroke engine. This being so, the two stroke must be a bigger and heavier unit, on account of its blower, and less economic on account of the power required for driving the blower.

This conclusion seems to be borne out by the accompanying comparison of published figure.s for one of the latest British four-stroke oil engines, and one of the latest American twostroke oil engines:— Type. Four-stroke, Two-slroke.

No. of cs,iin ders 6 3

Bore VA int. 4,4 ins.

Stroke 5 ins. 5 ms.

To tal swept

volume 288 cubic [U. 21.3 cubic in_ Maximum 85 80 Maximum govereed r.p,m 2.600 1.800

1001.b. (sq. in. 70 lb.fsg. n.

Weight, including starter motor... 658 lb. 1,175 lb.

Weight por h.h.p. 7.75 lb. 14.616.

Fuel consump .4 lb./ .45 lb. b.p.-br.