Modern Methods of Engine Overhauling

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

The Latest Equipment Used by the Birmingham Works of the Harold Andrews Grinding Co. to Ensure First-class Work

REAT as has been the improve ment in design and in manufac turing methods, it is possible that the overhauling of engines has made even greater strides during the past few years. That, at any rate, is the impression left by a visit to the works of the Harold Andrews Grinding Co., in Cheapside, Birmingham.

This concern, it may be mentioned, is responsible for much of the repair work required for a number of large fleets, including that of Shell-Mex and B.P., Ltd. In such cases definite limits are laid down, both as to accuracy and as to quality of material, so that the work can he carried out satisfactorily only with the aid of the most modern equipment.

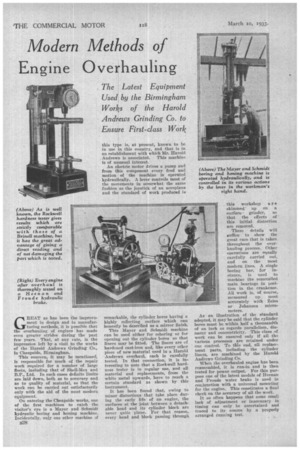

On entering the Cheapside works, one of the first machines to catch the visitor's eye is a Mayer and Schmidt hydraulic boring and honing machine. Incidentally, only one other machine Df B28 this type is, at present, known to be in use in this country, and that is in an establishment with which Mr. Harold Andrews is associated. This machine is of unusual interest.

An electric motor drives a pump and from this component every feed and motion of the machine is operated hydraulically. A lever controls most of the movements in somewhat the same fashion as the joystick of an aeroplane and the standard of work produced is remarkable, the cylinder bores having a highly reflecting surface which can honestly be described as a mirror finish.

This Mayer and Schmidt machine can be used either for reboring or for opening out the cylinder bores so that liners may be fitted. The liners are of hardened cast-iron and, like every other piece of new material used in a Harold Andrews overhaul, each is carefully tested. In that connection, it is interesting to note that a Rockwell hardness tester is in regular use, and all material and replacements, from the white metal upwards, have to reach a certain standard as shown by this instrumen t.

It has been found that, owing to minor distortions that take place during the early life of an engine, the surfaces at the joint between a detachable head and its cylinder block are never quite plane. For that reason, every head and block passing through.

this workshop a r e skimmed' up on a surface grinder, so that the effects of this initial distortion are removed.

These details will suffice to show the great care that is taken throughout the overhauling process. Other operations are equally carefully carried out, and on the most modern lines, A single boring bar, for instance, is used to machine the remetalled main bearings in position in the crankcase. All work is, of course, measured up most accurately with Zeiss or Johansen micrometers.

an illustration of the standard adopted, it may be said that the cylinder bores must he within half a. thousandth of an inch as regards parallelism, diameter and concentricity. This class of work can be ensured only if all the various processes are retained under one control. To this end, all replacement parts, including the cylinder liners, are machined by the Harold Andrews Grinding Co. When the overhauled engine has been reassembled, it is run-in and is then tested for power output. For this purpose one of the latest models of Heenan and Fronde water brake is used in conjunction with a universal mounting for the engine. This constitutes a final check on the accuracy of all the work.

It so often happens that some small lack of adjustment or inaccuracy in timing can only be ascertained and traced to its source by a properly arranged running test. As