Get more fire

Page 24

Page 25

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

levention on roads

by Brian B. Powell of the Cumbrian fire sereke

FIRE prevention in commercial vehicles is as essential as preventive maintenance.

When one looks into the problem in depth, the fire and mechanical protection of certain types of vehicles leaves much to be desired.

And from the fire-fighting point of view the task is also considerable. About one in every 500 goods vehicles in the UK has a fire that is attended by a fire brigade in any one year.

Goods vehicles carried 1,519m tonnes of freight in 1975 — that's 91.8 thousand million tonne-kilometres. Petroleum products amounted to 84m tonnes, and chemicals and fertilizers 55m tonnes.

• At the • moment legal requirements are very limited for hazardous cargoes in the transit period. When compared with legal requirements where hazardous products are made (at the factory or chemical complex) these production areas are well catered for in the realms of fire protection, either by legal enforcement or by insurance pressures

The transit period is the time and distance factor, often described by the emergency services as the -Who cares?" period. In transport circles it is recognised as an extension of the production line or

warehouse. It merits the same fire protection treatment.

The problems could be lessened if basic fire safety education were given to vehicle operators and staff transporting hazardous or other cargoes; perhaps in the same way that basic fire prevention and protection education is given at manufacturing premises.

The following suggestions would, I feel, lead to better fire safety standards in the road transport industry and provide a much needed assistance to the emergency services when dealing with hazardous products at incidents.

The maintenance and servic ing of goods and tanker vehi• cles is essential, but man) points need emphasizing af. their neglect can lead to ar outbreak of fire. Faults arise from lack of daily attention -such as to tyres. Drivers car assist by reporting immediate') any defects that come to theii notice.

Lorry crews should receive safety training covering such aspects as the hazard potentia of their loads and how to dea with emergencies. They shoulc know the correct method o calling the emergency servicE and how to alert and make USE of members of the public whc may be present and how to USE

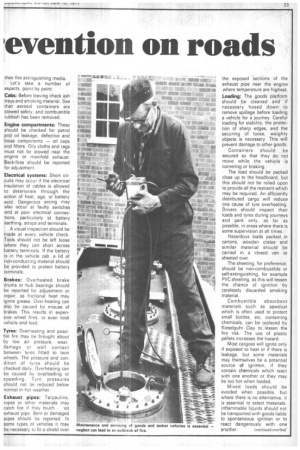

their fire extinguishing media. • Let's take a number of aspects, point by point: • Cabs: Before leaving check ash trays and smoking material. See • that aerosol containers are stowed safely; and combustible rubbish has been removed.

Engine compartments: These should be checked for petrol and oil leakage, defective and loose components — oil caps and filters. Oily cloths and rags must not be stowed near the engine or manifold exhaust. Back-fires should be reported for adjustment.

Electrical systems: Short circuits may occur if the electrical insulation of cables is allowed to deteriorate through the action of heat, age, or battery acid.. Dangerous arcing may also occur at faulty switches and at poor electrical connections, particularly at battery .earthing, straps and terminals.

A visual inspection should be made at every vehicle check. Tools should not be left loose where they can short across battery terminals. If the battery is in the vehicle cab, a lid of non-conducting material should be provided to protect battery terminals.

Brakes: Overheated brake drums or hub bearings should be reported for adjustment or repair, as frictional heat may ignite grease. Over-heating can also be caused by misuse of brakes. This results in expensive wheel fires, or even total vehicle and load.

Tyres: Overheating and possible fire. may be brought about by low air pressure, wear, damage or wall contact between tyres fitted to twin wheels. The pressure and condition of tyres should be checked daily. Overheating can be caused by ove,rloading or speeding. Tyre pressures should not be reduced below normal in hot weather.

Exhaust pipes: Tarpaulins, ropes or other materials may catch fire if they touch lot exhaust pipe. Bent or damaged pipes should be reported. In some types of vehicles it may be necessary to fit a shield over the exposed 'sections of the exhaust pipe near the engine where temperature are highest.

Loading: The goods platform should be cleaned and if necessary hosed down to remove spillage before loading a .vehicle for a journey. Careful loading for stability, the protection of sharp edges, and the securing of loose, weighty objects is necessary. This will prevent damage to other goods.

Containers should be secured so that they do not move while the vehicle is cornering or braking.

The load should be packed close up to the headboard, but this should not be relied upon to provide all the restraint which may be required. An efficiently distributed cargo will reduce one cause of tyre overheating. Drivers should inspect their loads and tyres during journeys and park only, as far as possible, in areas where there is some supervision at all times.

Hazardous loads packed in cartons, wooden crates and similar material should be carried in a closed van or .sheeted over.

The sheeting, for preference, should be non-combustible or self-extinguishing, for example PVC sheeting, as this will lessen the chance of ignition by carelessly discarded smoking material.

Combustible absorbent materials such as sawdust which is often used to protect small bottles, etc, containing chemicals, can be replaced by Kieselguhr Clay to, essen the fire risk. The use, of .plastic pellets increases the hazard.

Most cargoes will ignite only if exposed to heat or if there is leakage, but some materials may themselves be a potential source of ignition, if they contain chemicals which react with one another or they may be too hot when loaded.

Mixed loads should be avoided when possible, but where there is no alternative, it is essential to select materials. Inflammable liquids should not be transported with goods liable to spontaneous ignition or to react dangerously with one

another. 'continued overleaf

Extinguishing media for vehicle fires Engine fires Vaporising liquids; dry powder -extinguisher; consider fixed BCF installation.

Cab fires Water; extinguisher.

Tyre fires Tyre fire blanket; water-type extinguisher.

Fires in the load Dry powder (for fires involving leaking liquids).

Water type (for keeping surrounding areas cool and preventing fire spread).

Long-distance lorries should cart)/ a tyre fire blanket for covering and smothering; two jerrycans of water and a stirrup pump -economic, effective, easy to use, which is easy to replenish from another supply of water.

Vehicle structure: There should be structural fire protection to certain elements of its structure. This factor should take into account the fire resistance of the materials used in the vehicle construction. Surface spread of flame should be considered when one evaluates the fire potential of reinforced glass plastic types of material and the results of fire situations that have occurred in this type of material used in vehicle construction.

Vertical fire shields should be provided between cab and load and should meet the standards required for tanker vehicles transporting petroleum spirit.

Other aspects of vehicle structure protection is the fuel tanks, where fire resisting construction should form a barrier between the tanks and load platform areas of product tankage, and the wheel arches, where the same separation should be built in.

The road engine compartment should be fitted with a fixed BCF system. Portable extinguishers should be provided for general fire attack, suitable to the risk, and a tyre-fire jacket should be carried for wheel fires, and its smothering capacity for other areas.

Fixed fire-fighting installation should be provided in buses. Especially in areas which have poor access, ie (underslung central chassis engine) mountings.

Fire detection: Consideration should be given to the provision of automatic fire detection in areas of potential fires: wheel and axle areas; engine compartments; under-floor areas of certain types of buses: and sleeping cabs.

The reason for automatic smoke detection in vehicle cabs is that they are used for sleeping accommodation. This would provide fire warning in event of fire, to sleeping vehicle crews in parked up areas, thus protecting the lives of crew, vehicle and load.

Mechanical protection: The mechanical security factors in many cases require urgent re-appraisal.

An articulated vehicle is not uncommonly loaded with 100 by 50 gallon drums of nitro cellulose. All to often the only security to the load that is required is a rope to burn or break and in certain conditions the drums would come falling down (a ruptured drum, a leaking product, emitted vapours — constituents for fire).

Conclusion: Fire prevention in the transport industry requires as much attention as the time given to it in premises where hazardous products are made.

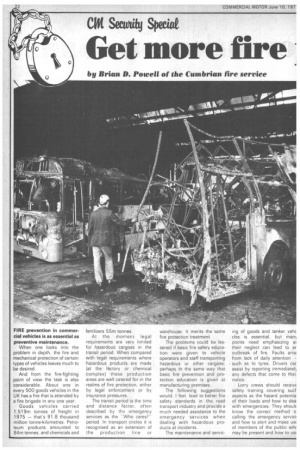

The following incident involved an articulated vehicle, carrying mixed chemical products; no doubt it could have been avoided. if basic fire prevention methods had been carried out, thus preventing what developed into a serious incident Which produced these factors.

1 Dangerous conditions and toxic risk for fire fighters.

2. Closing of a motorway.

3. Pollution of water coarses.

4. Farm livestock, 5 Traffic problems for the police.

6. Total damage to vehicle and load with the resultant cost factors, plus consequential matters.

7. Damage to motorway surface.

8. The involvement of a number of specialist teams -biologists, chemists, etc.

All this resulting from a tyre fire in which, had the means been available and the driver trained in its use, would never have developed in the way it did. Basic fire prevention routines were all that were needed.

In fact, the vehicle carried no extinguishers or other fire fighting media whatsoever. How many do?

Loss appraisal management would no doubt clearly identify the problems- , Cost evaluation a, Vehicle; b, Load; c, Replacement problem; d, Cost of replacement; e, Distance of involvement from base; f, Country of involvement from base; g, Consequential loss.

Remember prevention is better than cure.

To sum up, in road transport the fire protection and firefighting facilities leave much room for improvement.