Extruded aluminium Floor Sections

Page 82

If you've noticed an error in this article please click here to report it so we can fix it.

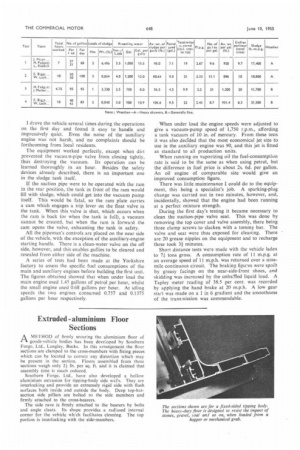

AMETHOD of firmty securing the aluminium floor of goods-vehicle bodies has been deve:oned by Southern Forge, Ltd., Langley, Bucks. In this arrangement the floor sections are clamped to the cross-members with fixing pieces which can be located to correct any distortion which may be present in the section. Floors assembled from these sections weigh only 21 lb, per sq. ft, and it is claimed that assembly time is much reduced.

Southern Forge. Ltd., have also developed a hollow aluminium extrusion for tipping-body side walls. They are interlocking and provide an extremely rigid side with flush surfaces both inside and outside the body. Deep top-hatsection side pillars are bolted to the side members and firmly attached to the cross-hearers.

The side rave is firmly attached to the bearers by bolts and angle cleats. Its shape provides a rad:used internal corner for the vehicle wb'ch facilitates cleaning. The top portion is interlocking with the side-members.