THE REPAIR• OF COMMERCIAL VEHICLES.

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Procedure in the Shops when Overhauling, Repairing, and Adjusting.

C , . . HASSIS ARE BROUGHT into workshops for • repairs, due either.to accidental damage or to . • general wear, of the working parts. In the latter case, when a thorough overhaul is required; the

• body should be removed before running .the chassis on to the pit, and for this purpose an overhead crane should be available in some convenient position. -Before lifting the body, care ought to be taken to see

that the rear mudguards are not attached to it. .

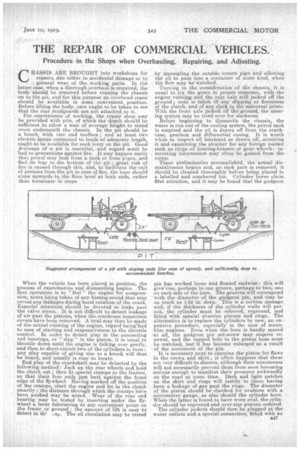

For eonvenience of working, the repair shop may be provided with pits, of which the depth should be sufficient to allow a man of average height to stand erect underneath the chassis. In the pit should be a bench, with vice and toolbox; and at least two . electric lamps connected to leads of adequate length, ought to be available for each lorry on the pit. Good drainage of a pit is essential, .and regard must be had to precautions against fire. It may happen easily that petrol may leak froma tank or from pipes, and find its Way to the bottom of the pit ; great risk. of fire is caused through this and, to facilitate the exit of persons from, the pit in case of fire, the base should slope upwards to the floor level at both ends, rather than terminate in steps.

When the vehicle has been placed in position, the process of examination and dismantling begins. The first operation is to " feel " the engine for compression, notes being taken of any hissing sound that. may reveal any leakages during hand rotation of the crank. Especial attention should be devoted to leaks past the valve sterna. It is not difficult to detect leakage of air past the pistons, when the.crankcase inspection covers have been removed. A trial may then be made of the actual-rimning of the engine, regard b.einglad to ease of starting and responsiveness to the throttle control. In order to detect play in the. connecting rod bearings, or " slap " in the piston, it is usual to throttle down until the engine is ticking over gently, and then to short-circuit two of the cylinders in turn : any play capable of giving rise to a knock will thus be heard, and usually is easy to locate.

End play of the crankshaft may be detected by the following method': Jack up the rear wheels and hold the clutch out;then fit special cramps to the Haines, so that their free ends just butt against the front edge of the flywheel: Having marked off the position of. the cramps, start the engine and let in the clutch smartly ; the distance through which the cramps have been pushed may be noted. Wear of the rear end bearing may be tested by inserting under the flywheel a lever fulcraming at any convenient point' on the frame or ground ; the amount of lift is easy to detect in the ..ai. The oil circulation may be tested by uncoupling the outside return pipe and allowing the oil to past into a container of some kind., when the flowmay be' watched. Turning to the consideration of the chassis, it is usual to try the gears in proper sequence, with the engine running and the rear axle still jacked off the i

ground; note s taken of any slipping or fierceness of the clutch, and of any slaCk in the universal joints. With the front axle jacked Off the ground, the steering system may be..tried-over for slaekness.

Before beginning to diSmantle the chassis, the water is run out of the cooling system, the petrol tank is emptied and the oil is drawn off from the crankcase, gearbox and differential casing. It is worth while to inspect all lubricant so drawn off, straining it and examining the strainer for any foreign mater such. as chips of bearing-brasses or gear wheels: interesting information may often be gained from the sump. These preliminaries accomplished, the actual dismantlement begins and, as each part is removed, it should be cleaned thoroughly before being placed in a labelled and numbered bin. Cylinder bores claim first attention, and it may be found that the gudgeon

pin has worked loose and floated endwise : this will give'rise, perhaps to one groove, perhaps to two, one on each side of the bore. The grooves will correspond with the diameter of the gudgeon pin, and may be as much as 1-32 in. deep. This is a serious damage and, if the thickness of the cylinder walls will permit, the cylinder must be rebored,reground, and fitted with special Oversize pistonsand rings. The alternative is to -replace the cylinders by new, an expensive procedure, especially in the case of 1110170bloc engines. Even when the bore is hardly scored at all, the gudgeon pin set-screw may require renewal, and the tapped hole in the piston boas must be watched, lest -it has become enlarged as a result Of the movement of the pin.

It is necessary next to examine the piston for flaws in the crown and skirt ; it often happens that these are very difficult to discern, although their minuteness will not necessarily prevent them from soon becoming serious enough to manifest their presence awkwardly on the road at some time. Dark and light patches on. the skirt and rings will testify to there having been a leakage of gas past the rings. The diameter of the piston should be checkedfor ovalness with a . micrometer gauge, as also should the cylinder bore. When the 'latter is found to have worn oval, the cylinder should be reground and over-size pistons ordered. The cylinder jackets should then be plugged at water outlets and a special connection, fitted with an

air valve, is put into the remaining water inlet (after the water jacket his been partly tilled with water). A pressure of about 60 lb. per sq. in. is introduced by means of an air plump . and, with the aid of. an electric torch, the inside of the cylinders may be ex-amined for possible cracks. Sometimes cniy a slight " weeping " is noticeable. If this be very small, it may be ignored; but if the " weeping " should assume the form of a constant drip or a very light spray, cementation with iron cement will be a remedy in most cases where the crack occurs away from the path of the piston. Obviously, if the crack be more serious, the welding plant is' broughtinto operation, providing the crack be accessible. By cutting away the jacket, almost any crack can be welded satisfactorily on' the cylinder head, but when the weld has to be done in the bore, in the case of single,cylinders, or cylinders cast in pairs, a new cylinder, or pair, will pay better in the long run, as the weld and the bore would have to be reground and new oversize Pistons fitted. The valve seats in the cylinder block should now be inspected and, if pitted, should be lapped out. Where the seats have been burnt, Which is rare, new seats will have to be machined out and new valves made to suit.

The crankcase also has to be examined minutely for cracks ; in the case of some five-bearing cranks, these cracks are prone to develop under the centre web. Oilways should be tested under pressure. In checking the crankshaft-, a surface table should be used ; tests are carried out for alignment and care is taken to. notice any flaws that may have developed in the webs, any distortion of keys, or any wear on splines.

In testing for ovalness of the journals and big-end bearings, of course, a micrometer gauge has to be Wed: these bearings are often found to have worn oval, and in these circumstances must necessarily be reground, great care being taken after this operation to flush the oilways through with paraffin, in order to ensure that no dust has lodged in them.

Bedding-in the big-end bearings has then to be carried out to accommodate them to the smaller diameter of journal, it being important here to remember that the correct radius must be formed in each end of the bearing—a point often neglected in the case of the journal, also, when the latter is reground. It is essential that the radius after regrinding should be not less than that originally, provided by the designer, since absence of a, radius tends very materially to weaken the journal. All operations incidental to the repair, of big-end and main bearings should be undertaken by some one "all fait" with this job, who can feel the bearings correctly.

Camshaft bearings next receive attention and should be renewed, if it be found that they have worn •• • to any appreciable extent ; where ball or roller bearings are fitted, it is important to see that there is no end play or creep, and that the bails in the races have not become pitted. No attempt should be made to scrape ball bearing journals ; these should be sent to a ball bearing specialist to be reground and fitted with new balls; tne cost is not great, and will be amply justified by the better job that is ensured.

A Jew precautias ought to be mentioned here, as necessary to be observed in the re-erection of the chassis. The engine should be aligned very carefully with the frame, packing being used for the purpose where necessary. Slinging it into place and bolting it down in a haphazard fashion will result in heavy wear on the clutch -and universal joints. Inspection of the clutch details entails careful attention to the condition of the spigot bearing, and also the oilways: this bearing is exposed to the danger of considerable wear, if the grease has been unable to reach it ; and wear is liable to be incurred also on the universal joints immediately to the rear of the clutch. The clutch lining should be dressed, or, if necessary, renewed.

Where the sliding. block and box type universal jOint is used, attention ought to be devoted to end wear that may have taken place on the pin block or slide. The lubrication of these joints is Often neglected, so that the wear is frequently a serious item. Where the pins are badly worn they may be made good by cutting them off and drilling out a hole i 1-64th n. in diameter larger than the previous size of he pin ; a new pm is turned and fitte4.4. into the crosshead and pegged into place. The pins are then case-hardened and ground to suit new blocks, which also are case-hardened and ground.

It will probably be found necessary to replace the slide, which is often subject to indentation due to the side thrust caused by the worn blocks. This may be accomplished by milling the slides wider and fitting hardened steel liners'by means of countersunk screws. When fabric joints are used, the bolts which clamp the coupling fabrics or leathers together should be made a good fit in the hole in order to obviate any tendency to chafe, with the result of short life alike to joints and bolts.

Where universal joints behind the clutch are badly worn and the clutch centre shows signs of excessive wear, it is advisable to check carefully the alignment of the engine with the gearbox and in relation to the frame. Sag in the chassis side members may account for much, especially in the absence of three-point engine suspension. Another cause of wear on these parts is that the gearbox supports may have worked loose.