Volvo's blow by blow

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

• By using a new technique called sequential turbocharging, Volvo Trucks claims the power output of today's truck diesel engines could be increased by 10% — without jeopardising reliability or durability — and with better fuel economy.

Development of the system by the Swedish truck manufacturer is already well advanced, and a sequentially-turbocharged version of Volvo's 12 litre charge-cooled TD120 engine has been bench-tested producing 310kW (415hp) governed at 2,200rpm.

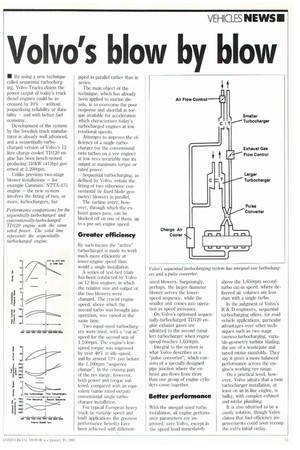

Unlike previous two-stage blower installations — for example Cummins' NTTA-475 engine — the new system involves the fitting of two, or more, turbochargers. but Performance comparisons for the sequentially-turbocharged and amventionally-turbocharged TD 120 engine with the same rated power. The solid line represents the sequentiallyturbocharged engine. piped in parallel rather than in series.

The main object of the technique, which has already been applied to marine diesels, is to overcome the poor response and shortfall in torque available for acceleration which characterises today's turbocharged engines at low rotational speeds.

Attempts to improve the efficiency of a single turbocharger (or the conventional twin turbos on a vee engine) at low revs invariably mar its output at maximum torque or rated power.

Sequential turbocharging, as defined by Volvo, entails the fitting of two otherwise conventional (ie fixed blade geometry) blowers in parallel.

The turbine entry, however, through which the exhaust gases pass, can be blocked off on one of them, up to a pre-set engine speed.

Greater efficiency

By such means the "active" turbocharger is made to work much more efficiently at lower-engine speed than would a single installation.

A series of test-bed trials has been conducted by Volvo on 12 litre engines, in which the relative size and output of the two blowers were changed. The crucial engine speed, above which the second turbo was brought into operation, was varied at the same time.

Two equal-sized turbochargers were tried, with a "cut-in" speed for the second unit of 1,100rpm. The engine's lowspeed torque was improved by over 40% at idle-speed, and by around 12% just before the 1,100rprn "sequence change". In the cruising part of the rev range, however, both power and torque suffered, compared with an equivalent (same rated output) conventional single-turbocharger installation.

For typical European heavy truck tie variable speed and load) applications the greatest performance benefits have been achieved with different sized blowers. Surprisingly, perhaps, the larger diameter blower serves the lowerspeed sequence, while the smaller unit comes into operation as speed increases.

On Volvo's optimised sequentially-turbocharged T1J120 engine exhaust gases are admitted to the second (smaller) turbocharger when engine speed reaches 1,650rpm.

Integral to the system is what Volvo describes as a "pulse converter", which consists of a specially-designed pipe junction where the exhaust gas-flows from more than one group of engine cylinders come together.

Better performance

With the unequal-sized turbo installation, all engine performance parameters are improved, says Volvo, except in the speed band immediately above the 1,650rpm secondturbo cut-in speed, where delivered air volumes are less than with a single turbo.

In the judgment of Volvo's R & D engineers, sequential turbocharging offers, for road vehicle applications, particular advantages over other techniques such as two-stage (series) turhocharg,ing, variable-geometry turbine blading, the use of a wastegate and tuned intake manifolds. They say it gives a more balanced performance across the engine's working rev range.

On a practical level, however, Volvo admits that a twin turbocharger installation, at least on an in-line engine, is bulky, with complex exhaust and intake plumbing.

It is also admitted to be a costly solution, though Volvo claims that fuel efficiency improvements could soon recoup the extra initial outlay.