Starter motors, 3

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

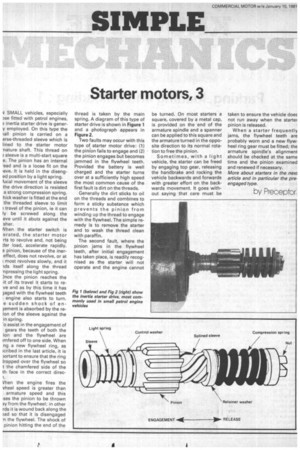

J SMALL vehicles, especially se fitted with petrol engines, ) inertia starter drive is genery employed. On this type the ialI pinion is carried on a arse-threaded sleeve which is lined to the starter motor nature shaft. This thread on ) sleeve is a multi-start square e. The pinion has an internal .ead and is a loose fit on the eve. It is held in the disenged position by a light spring. xial movement of the sleeve the drive direction is resisted a strong compression spring. hick washer is fitted at the end the threaded sleeve to limit travel of the pinion, ie it can ly be screwed along the eve until it abuts against the sher.

when the starter switch is erated, the starter motor rts to revolve and, not being der load, accelerate rapidly. pinion, because of the inereffect, does not revolve, or at most revolves slowly, and it -ids itself along the thread -npressing the light spring. )nce the pinion reaches the it of its travel it starts to rove and as by this time it has )aged with the flywheel teeth engine also starts to turn. e sudden shock of en)ement is absorbed by the reion of the sleeve against the in spring.

-o assist in the engagement of gears the teeth of both the ion and the flywheel are imfered off to one side. When ng a new flywheel ring, as icubed in the last article, it is )ortant to ensure that the ring iropped over the flywheel so t the chamfered side of the th face in the correct direc).

Vhen the engine fires the vheel speed is greater than armature speed and this ses the pinion to be thrown 3 y from the flywheel; in other rds it is wound back along the )ad so that it is disengaged n the flywheel. The shock of pinion hitting the end of. the thread is taken by the main spring. A diagram of this type of starter drive is shown in Figure 1 and a photograph appears in Figure 2.

Two faults may occur with this type of starter motor drive: (1) the pinion fails to engage and (2) the pinion engages but becomes jammed in the flywheel teeth. Provided the battery is well charged and the starter turns over at a sufficiently high speed the most common cause of the first fault is dirt on the threads.

Generally the dirt sticks to oil on the threads and combines to form a sticky substance which prevents the pinion from winding up the thread to engage with the flywheel. The simple remedy is to remove the starter and to wash the thread clean with paraffin.

The second fault, where the pinion jams in the flywheel teeth, after initial engagement has taken place, is readily recognised as the starter will not operate and the engine cannot be turned. On most starters a square, covered by a metal cap, is provided on the end of the armature spindle and a spanner can be applied to this square and the armature turned in the opposite direction to its normal rotation to free the pinion.

Sometimes, with a light vehicle, the starter can be freed by engaging top gear, releasing the handbrake and rocking the vehicle backwards and forwards with greater effort on the backwards movement. It goes without saying that care must be taken to ensure the vehicle does not run away when the starter pinion is released.

When a starter frequently jams, the flywheel teeth are probably worn and a new flywheel ring gear must be fitted; the armature spindle's alignment should be checked at the same time and the pinion examined and renewed if necessary.

More about starters in the nem article and in particular the preengaged type.

by Preceptor