A NEW KIRKSTALL AXLE FOR SIX-WHEELERS.

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

A Resume of Recently Published Patent Specifications.

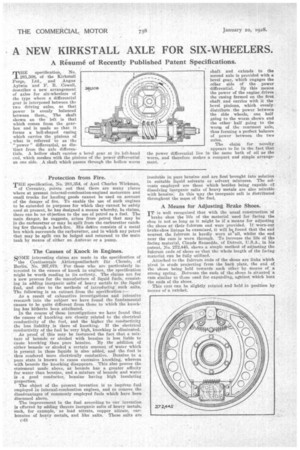

THE specification, No.

281,508, of the Kirkstall Forge, Ltd., and Angus Aylwin and F. R. Cowell, describes a new arrangement of axles for six-wheelers of the type where a differential gear is interposed between the two driving axles, so that power is evenly balanced between them, The shaft shown on the left is that which comes from the gearbox and is made so that it forms a bell-shaped casing which carries the pinions of what is referred to as the " power " differential, as distinct from the axle differentials. A hollow shaft carries a bevel gear at its left-hand end, which meshes with the pinions of the power differential on one side. A shaft which passes through the hollow worm

Protection from Fire.

THE specification, No. 281,354, of Axel Charles Wickman,

of Coventry, points out that there are many places where at present internal-combustion-engined motorcars and small trucks for hauling goods cannot be used on account of the danger of fire. To enable the use of such engines to be extended to purposes for which they cannot be safely used at present, he has designed a means whereby, he claims, there can be no objection to the use of petrol as a fuel. The main danger, he suggests, arises from petrol that may be in the carburetter or may be spilt from the carburetter catching fire through a back-fire. His donee consists of a metal box which surrounds the carburetter, and in which any petrol that may be spilt can be lodged and returned to the main tank by means of either an Autovac or a Pump.

The Causes of Knock in Engines.

SOME interesting claims are made in the specification of

the Continentale Aktiengesellschaft fiir Chemie, of Berlin, No. 207,079. For those who are particularly interested in the causes of knock in engines, the specification might be worth reading in its entirety. The claims are for a new process for the manufacture of liquid fuels, consisting in adding inorganic salts of heavy metals to the liquid fuel, and also to the methods of introducing such salts. The following is an extract from the specification:— As a result of exhaustive investigations and intensive research into the subject we have found the fundamental causes to be quite different from those to which the knocking has hitherto been attributed.

In the course of these investigations we have found diet the causes of knocking are closely related to the electrical conductivity of the fuel, and the higher the conductivity the less liability is there of knocking. If the electrical conductivity of the fuel be very high, knocking is eliminated.

As proof of this may be instanced the fact that a mixture of benzoic or alcohol with benzine is less liable to cause knocking than pure benzine. By the addition of either benzoic or alcohol a certain amount of water which is present in these liquids is also added, and the fuel is thus rendered more electrically conductive. Benzine in a pure state is known to cause excessive knocking, whereas with benzole the knocking disappears. This also proves the statement made above, as benzoic has a greater affinity for water than benzine, and a mixture of benzoic and water is a good conductor, benzine having high insulating properties: The object of the present invention is to impiove fuel employed in internal-combustion engines, and to remove the disadvantages of commonly employed fuels which have been discussed above.

The improvement in the fuel according to our invention is effected by adding thereto inorganic salts of heavy metals, such, for example, as lead nitrate, copper nitrate, carbonates of heavy metals, and like salts. These salts are shaft and extends to the second axle is provided with a bevel gear, which engages the other side of the power differential. By this means the power of the engine I drives the casing formed on the first shaft and carries with it the bevel pinions, which evenly distribute the power between the side wheels, on half going to the worm shown and the other half going to the worm of the rearmost axle, thus forming a perfect balance of power between the two axles.

The claim for novelty appears to lie in the fact that the power differential lies in the same bath of oil as the worm, and therefore makes a compact and simple arrangepent.

insoluble in pure benzine and are first brought into solution in suitable liquid solvents or solvent mixtures. The solvents employed are those which besides being capable cf dissolving inorganic salts of heavy metals are also mixable with benzine_ In this Aay the inorganic salt is distributed throughout the mass of the fuel.

A Means for Adjusting Brake Shoes.

TT is well recognized that with the usual construction of

brake shoe the life of the material used for facing the shoe is not so long as it might be if a means for adjusting the shoes at their fulcrum end were provided. If worn-out brake-shoe linings be examined, it will b‘found that the end nearest the fulcrum is hardly worn at all, whilst the end near the cam is worn through. To increase the life of the facing material, Claude Sauzedde, of Detroit, U.S.A., in his patent, No. 272,445, shows a simple method of adjusting the fulcrum ends of shoes so that the whole length of the facing material can be fully utilized.

Attached to the fulcrum ends of the shoes are links which pivot in studs projecting from the back plate, the end of the shoes being held towards each other by means of a strong spring. Between the ends of the shoes is situated a cam similar to those used for expanding, against which butt the ends of the shoes.

This cam can be slightly rotated and held in position by means of a ratchet. •