HINTS ON MAINTENANCE.

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

Lapping the Crankpins of Steam Engines. Big-end Nuts for Y and B-type Daimlers. Preventing Overheating on the Peerless.

Smoothing Scored Crankpins on Steam Engines.

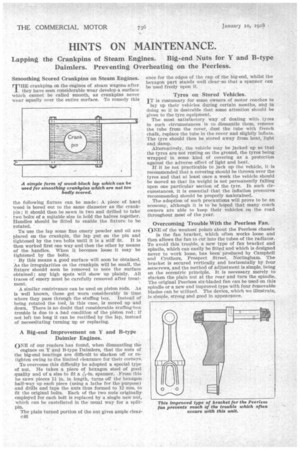

THE crankpins on the engines of steam wagons after they have seen considerable wear develop a surface which cannot be called smooth, as crankpins never wear equally over the entire surface. To remedy this

the following fixture can be made: A piece of hard wood is bored out to the same diameter as the crankpin ; it should then be sawn in two and drilled to take two bolts of a suitable size to hold the halves together. Handles should be fitted to enable the fixture to be rotated.

Ta use the lap some fine emery powder and oil are placed on the crankpin, the lap put on the pin and tightened by the two bolts until it is a stiff fit. It is then worked first one way and then the other by means of the handles. When it becomes loose it may be tightened by the bolts.

-By this means a good surface will soon be obtained. As the irregularities on the crankpin will be small, the fixture should soon be removed to note the surface obtained ; any high spots will show up plainly. All traces of emery must be carefully removed after treatment.

A similar contrivance can be used on piston rods. As is well known, these get worn considerably in time where they pass through the stuffing box. Instead of being rotated the tool, in this case, is moved up and down. There is no doubt that considerable stuffing-box trouble is due to a bad condition of the piston rod ; if not left too long it can be rectified by the lap, instead of necessitating turning up or replacing.

A Big-end Improvement on Y and B-type • Daimler Engines.

ONE of our readers has found, when dismantling the engines on Y and B-type Daimlers, that the nuts of the big-end bearings are difficult to slacken off or retighten owing to the limited clearance for their corners.

To overcome this difficulty he adopted a special type of nut. He takes a piece of hexagon steel of good quality and of a size to fit a -juin. spanner. From this he saws pieces 1 in. in length, turns at the hexagon half-way up each piece (using a lathe for the purpose) and drills and taps the nuts thus formed to 12 mm. to fit the original bolts. Each of the two nuts originally employed for each bolt is replaced by a single new nut, which can be castellated in the usual way for a splitpin.

The plain turned portion of the nut gives ample cleare46 ance for the edges of the cap of the big-end, whilst the hexagon part stands well clear-so that a spanner can be used freely upon it.

Tyres on Stored Vehicles.

IT is customary for some owners of motor coaches to lay up their vehicles during certain months, and in doing so it is desirable that some attention should be given to the tyre equipment.

The most satisfactory way of dealing with tyres in such circumstances is to dismantle them, remove the tube from the cover, dust the tube with french chalk, replace the tube in the cover and slightly inflate. The tyre should then be stored away from heat, light and damp.

Alternatively, the vehicle may be jacked up so that the tyres are not resting on the ground, the tyres being wrapped in some kind of covering as • a protection against the adverse effect of light and heat.

If it be not practicable to jack up the vehicle, it is recommended that a covering should be thrown over the tyres and that at least once a week the vehicle should be moved so that its weight is not permanently falling upon one particular section of the tyre. In such circumstances, it is essential that the inflation pressures recommended should be properly maintained.

The adoption of such precautions will prove to be an economy, although it is to he hoped that many coach owners are able to keep their vehicles on the road throughout most of the year.

Overcoming Trouble With the Peerless Fan.

ONE of the weakest points about the Peerless chassis

is the fan bracket, which often works loose and then allows the fan to cut into the tubes of the radiator. To avoid this trouble, a new type of fan bracket and spindle, which can easily be fitted and which is designed never to work loose, has been produced by Campbell and Crothers, Prospect Street, Nottingham. The bracket is secured vertically and horizontally by four setscrews, and the method of adjustment is simple, being on the eccentric principle. It is necessary merely to slacken the plain nut at the rear and turn the spindle. The original Peerless six-bladed fan can be used on this spindle or a new and improved type with four removable blades can be utilized. The device, which we illustrate, is simple, strong and good in appearance.