THE DESIGNER'S EYE ON MAINTENANCE COSTS.

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

The Provision Made on Dennis Chassis in Order to Facilitate Maintenance and Secure Economy Therein.

• WITH a view to ascertaining what has been done in V V the way of detail improvement which will reduce the cost of maintenance of the Dennis chassis and to simplify th.) renewal of such parts as are affected by wear, we visited the works of Messrs. Dennis Brothers at Guildford. Before inspecting the details of the various models, we were shown the new addition to the works, which is in the form of one large square building covering three and a half acres. When this building is added to the already large range of shops the capacity of the Dennis works should be doubled.

As usual in these visits, made for the purpose of procuring detail information relating to upkeep, we started with what is still the most vulnerable part of a motor vehicle—the big-end.

Here we found that one matter has been attended to— namely, the method of inducing oil to find its way between the crank journal and the bearing. Oil under pressure is forced through the crankshaft in the usual manner, and is discharged into the big-end bearing, where it is carried by a groove in the cap bearing to the division between the halves of the bearing. On the side of the bearing which is opposed to the revolving shaft there are depressions which taper away to nothing, the oil being dragged into the depressions by the revolving shaft, sad, as the depression gradually dits away, a tapering film of oil is entrapped between the bearing surface and the journal, thus producing an effect similar to the Michell marine thrust bearing. We are surprised that more attention has not been given to methods like this, as in many cases the bevelled edge of the brass acts as a scraper or squeegee instead of leading the oil where it should go. Shims are fitted, but not as we should expect to see them, as they do not separate the brasses, but only lie between the faces of the steel connecting rod, the brasses being secured from rotation by a dowel pin.

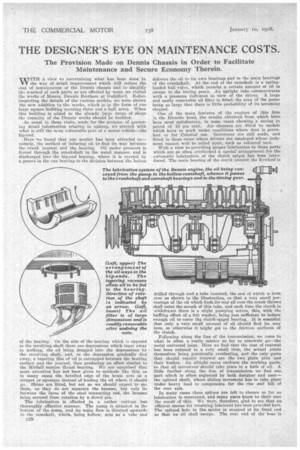

The lubrication is effected in a rather curious but thoroughly effective manner. The pump is situated in the bottom of the sump, and its main flow is directed upwards to the camshaft, which, being hollow, acts as a tube and

delivers the oil to its oWn bearings and to the main bearings of the crankshaft. At the end of the camshaft is a springloaded ball valve, which permits a certain amount of oil to escape to the timing gears. An upright tube communicates with a pressure indicator in view of the driver. A large and easily removable oil filter is fitted, the area of the gauze being so large that there is little probability of its becoming clogged. One of the main features of the engines of this firm is the Ricardo head, the results obtained from which have been most satisfactory, in some cases showing a saving in petrol of 15 per cent. Air cleaners are fitted to models which have to work under conditions where dust is prevalent or for Colonial use. Governors are still made, and fitted in those cases where drivers are employed whose judgment cannot well be relied upon, such as coloured men.

With a view to providing proper lubrication to those parts which are so often overlooked a special arrangement for the automatic lubrication of the clutch spigot has been introduced. The main bearing of the crank nearest the flywheel is

drilled through and a tube inserted, the end of which is bent over as shown in the illustration, so that a very small percentage of the oil which finds its way all over the crank throws shall enter the mouth of this tube, and each time the clutch is withdrawn there is a slight pumping action, this, with the baffling effect of a felt washer, being just snfficient to induce enough oil to enter the clutch-spigot hearing. It is essential that only a very small amount of oil should find its way here, as otherwise it might get to the friction surfaces of the clutch.

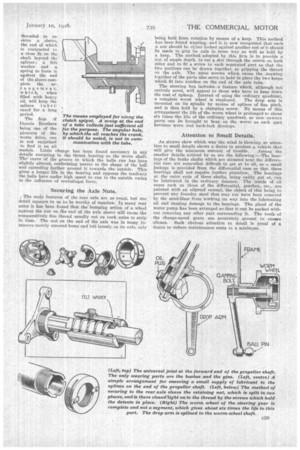

Following along the line of the transmission, we come to what is often a costly matter so far as renewals go—the metal universal joint. Here we find that the cost of renewal has been reduced to a very small item, the actual joints themselves being practically everlasting, and the only parts that should require renewal are the two plain pins and their bushes. An oiltight cover encloses the working parts, so that all movement should take place in a bath of oil. A little farther along the line of transmission we find one part which is often neglected by both designer and user— the splined shaft, where sliding movement has to take place under heavy load to compensate for the rise and fall of the rear axle.

In many cases these splines are left to chance so far as lubrication is concerned, and many users know to their cost the result of this. We were, therefore, glad to see that an efficient means for retaining lubricant has been provided here. The splined hole in the spider is stopped at its front end so that no oil shall escape. The rear end of the boss is threaded to receive a sleeve, the end of which is contracted to a dose fit on the shaft beyond the splines; a felt washer and a spring to force it against the end of the sleeve complete the arrangement, which, when filled with heavy oil, will keep the splines 1 u

cated for a long period.

The firm of Dennis Brothers being one of the pioneers of the worm drive, one is not surprised to find it on all models. Little change has been found necessary in any details excepting in the thrust bearing on the worm shaft. Thecurve of the groove in which the balls run has been slightly altered, conforming nearer to the shape of the ball and extending farther around it towards the outside. This gives a longer life to the bearing and opposes the tendency the balls have under high speed to run to the outside owing to the influence of centtifugal force.

The means employed for oilmg the clutch spigot. A scoop at the end of a tube collects just sufficient oil for the purpose. The angular hole, by which the oil reaches the crank, it should be noted, is not in com munication with the tube.

Securing the Axle Nuts.

The nuln features of the rear axle are as usual, but one detail appears to us to be worthy of mention. In many rear axles it has been found that the bumping action of a wheel against the nut on the end of the axle sleeve will cause the comparatively fine thread usually Cut on such axles to strip in time. The nut on the end of the axle was in many instances merely screwed home and left loosely on its axle, only being held from rotation by means of a keep. This method has been found wanting, and it is now recognized that such a nut should be either locked against another nut or it should be made to grip its axle in some way as well as held by a keep, The method adopted by this firm is to provide a nut of ample depth, to cut a slot through the centre on both sides and to fit a screw to each separated part so that the two portions can be drawn together, so gripping the thread on the axle. The same screws which cause the drawing together of the parts also serve to hold in place the two keeps which fit into notches on the end of the axle tube.

The steering box includes.a feature which, although not entirely novel, will appeal to thoso who have to keep down the cost of upkeep. Instead of using the ordinary quadrant, a complete worm wheel is employed. The drop arm is mounted on its spindle by means of splines of fine pitch, and is then held by a damping screw. By means of this arrangement the life of the worm wheel is prolonged to about six times thd life of the ordinary quadrant, as new unworn parts can be brought to bear on the worm as each part becomes worn and back-lash develops.

Attention to Small Details.

As straws show which way the wind is blowing, so attention to small details shows a desire to produce a vehicle that will give the minimum amount of trouble. Among the smaller details noticed by us are the following :—Thc bearings of the brake shafts which are situated near the differential case are somewhat difficult to get at to oil, so a small leakage is provided from the differential case so that these bearings shall not require further attention. The bearings at the outer ends of these shafts, being easily got at, can be lubricated in the ordinary manner. The inside of all cases such as those of the differential, gearbox, etc., are painted with an oilproof enamel, the object of this being to prevent any foundry sand that may not have been removed by the sand-blast from working its way into the lubricating oil and causing damage to the bearings. The gland of the water pump has been arranged so that it can be packed without removing any other part surrounding it. The teeth of the change-speed gears are accurately ground to ensure silence. Such obvious attention to detail is proof of a desire to reduce maintenance costs to a minimum.