THE COMING MOI TRANSPORTATION.

Page 14

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

ACOMMENCEMENT was made in the United States last yearwith a system of transportation by container andcontainer railway ensplatform and motor lorry, which possesses such merit that we foresee its general adoption by railway companies, supported by manufacturers and traders. The system was the outcome of the railroad congestion that prevailed during the war, and it aimed at the reduction of the transportation losses which arose from that congestion, and the avoidance of the tying up of industry which was an unavoidable consequence.

It is common knowledge that the railway truck spends an extraordinarily small proportion of its life in actual running or loading and unloading—probably about a per cent. The remaining 93 per cent. of its life is spent in sidings, mainly waiting for the removal of its load, platforms and places where they can be unloaded and reloaded suffering from the cangestion caused by the present system of handling goods and raw materials in small parcels. Again, consignees are often not ready to accept delivery, and prefer to use the trucks as a storage warehouse, paying demurrage, the amount of which bears no real relation to the fact that the truck is thus pre

vented from being used in fostering industry. A few shillings a day for demurrage is an absurd exchange for the value of the use of the truck in the rapid transport of raw materials required to keep the wheels of industry turning, or of finished goods that can be turned again into fluid capital.

Again, there are the evils of robbery and pilferage, of damage and breakage the need for checking and re-handling, the delays breakage, shippers and consignees. Much of all this can be eliminated by the employment of containers, which are used to a very small extent in this country, as, for example, in the transport of registered baggage between London railway termini and the Continent, whereby the saving of two handlings at the ship's side is effected.

Loss of and damage to freight has, since the war, grown to be one of the heaviest leakages in the transport industry, entailing extensive police and supervisory forces, with extra expense in the provision of stronger packages, yet, in spite of all the extra trouble and expense, the economic waste continues. In America, the amount paid annually in claims for loss of and damage to freight increased by four times between the years 1914 and 1920, whilst, of course, -the individual injury to business must have been considerably greater.

Under the ordinary system of handling loads that are less than a railway truck load, the goods are handled item by item from factory to motor vehicle, motor vehicle to goods depot, goods depot to railway truck, truck to depot, depot to motor, motor to warehouse. The amount of labour involved en route from manufacturer to trader or distributor is colossal.

The container system by contrast provides that the portable container shall be loaded and locked at the door of the manufacturer's or consignor's factory or warehouse, conveyed by motor lorry to the railway goods yard, and transhipped by crane to the railway container car, where the steel bulwarks or sides and ends provide ample protection against opening the container in transit. At the end of the rail journey a crane would lift the container on to a motor lorry, by which it would be conveyed to its destination, and there the goods would be handled for the first time since they left the consignor's. If it be required to use the container as a warehouse, the loss of transport facilities by the locking up of a container is infinitely less than if a railway truck were compelled to stand idle in a siding, and the container being upon the premises of the consigner is sure to provide a greater safeguard against pilferage than would a truck in a siding. The rolling stock for the transport of the containers would not need to be idle to the extent of more than a fraction of its actual life. Obstruction of sidings, and excessive shunting would be avoided by the consequent reduction of the misuse of rolling stock for storage purposes. The ease and speed with which container ears can be unloaded and reloaded means that rolling stock can practically always be kept on the move.

Much costly packing and crating becomes unnecessary when the container is employed. It can be made quite weatherproof, and the method of handling it by crane prevents roughness in treatment, tending to the injury and breakage of fragile or delicate contents.

There is no limitation to the type of container or its use, but, of course, it is essential that standard dimensions be adopted, so that the containers shall be absolutely interchangeable. They can be made of steel throughout, with wide doors at the ends, or as tanks, or equipped as refrigerators.

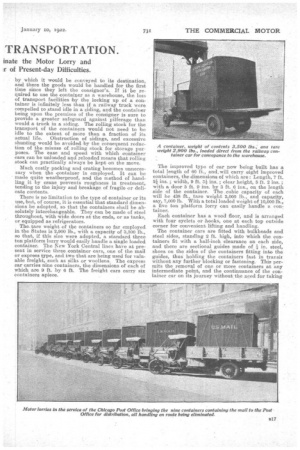

The-tare weight of the containers so far employed in the States is 2,900 11;., with a capacity of 3,500 lb., so that, if this size were adopted, a standard three ton platform lorry would easily handle a single loaded container. The New York Central lines have at present in service three container cars,. one of the mail or express type, and two that are being used for valuable freight, such as silks or woollens_ The express car carries nine containers, the dimensions of each of which are 9 ft. by 6 ft. The freight cars carry six containers apiece. The improved type of car now being built has a total length of 60 ft., and, will carry eight improved containers, the dimensions of which are : Length, 7 ft. 21 ins. ; width, 9 ft. 3,24ins. ; clear height, 8 ft. 2 ins. ; with a door 5 ft. 9 ins. by 3 ft. 6 ins., on the length side of the container. The cubic capacity of each will be 438 ft., tare weight 3,000 lb., and capacity, say, 7,000 lb. With a total loaded weight of 10,000 lb., a five ton platform lorry can easily handle a con7 tamer.

Each container has a wood floor, and is arranged with four eyelets or hooks, one at each top outside corner for convenient lifting and handling.

The container cars are fitted with bulkheads and steel sides, standing 2 ft. high, into which the containers fit with a half-inch clearance on each side, and there are sectional guides made of / in. steel, shoeson the sides of the containers fitting into the guides, thus holding the containers fast in transit without any further blocking or fastening. This permits the removal of one or more containers at any intermediate point, and the continuance of the container car on its journey without the need for taking any .further 'safeguards to prevent the containers shifting or falling over because of the oscillation of the car.

Tests of the express, or mail, type of container car on the New York Central lines showed that with an ordinary crane nine containers can be transferred from the car to lorries in 21 minutes, and the car can be reloaded with other containers in about the same time. With special handling facilities, even this short time could be improved upon. In mail service alone, considerable loss in transit would be prevented by the use of the container, and the system involving its employment. Considerable saving in labour and handling would be effected as well as the saving to the railway companies of equipment.. Quick transfers would reduce delays at connections between different arms of a service. Each container car -would carry a greater net load than n. railway truck of the same dimensions, but the weight of a container would be more than the weight of a lorry body, so that there would be a slight loss of economy over the road secbon of the journey. This, however, would be more than counterbalanced by the saving of time in loading and unloading the lorry, which would be able, in consequence, to cover a greater daily mileage, and to spread its standing charges, including wages, over a greater ton mileage.

The container system, in fine, tends to a co-ordination of the use of the motor lorry and railway truck, and it must hold far-reaching economic possibilities in transport operations in the future.

It was at a meeting of the.,American Society of Mechanical Engineers, that Mr. Walter C. Sanders,. of the Equipment Engineering Department of the New York Central lines, read a most interesting paper on this subject. Upon the contents of that paper we have very largely drawn in the preparation of this article, and to the editor of The Eng-ineer we are indebted for the use of the illustrations which accompany it.