THE UPKEEP OF STEAM WAGONS.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

No. 9.—Dismantling and Re-erecting.

The length of time that a wagon should run before it requires thoroughly oveahauling will vary accord ing to circumstances. But assuming that it has been in constant use, and that it has received the attention described in these articles, a new machine should be overhauled after about two years running ; after' wards it should be done every year. The wagon should be completely stripped, and every part cleaned and adjusted or It will be found extremely useful if a record is kept of all re pair s, etc., effected to each wagon ; in fact, such a plan must be adopted if proper running costs are to be kept for business purposes. These records Fig. 23, Knocki will supply data which will make it possible to have preparations made to facilitate carrying out the overhaul ; sueh as what new parts will probably be required, and where repairs and adjustments are most likely to be necessary. The records of the driver's reports will also indicate what parts are out of order and need attention. If the person who is to carry out the overhaul is not supplied with such records, the best course would be for him to take the wagon • out for a trial run, in order to find out, so far as possible, what was actually wrong with it. For although the driver can always tell that something is wrong, his mechanical knowledge is not always sufficient for him correctly to diagnose the faults. A brief outline of the best method of dismantling a wagon is as follows :—First take off the body (and place it .where it will not get knocked about), the wheel guards and the engine covers. Then remove the driving chain, placing wood planks underneath for it to drop on, so as not to damage it. Now pack up'the back end of the chassis frame, and after disconnecting the brake, connecting rods and the radius rods, take off the hind wheels and remove the hind axle, fittings and spring gear. The brake gear and • steering gear can, then be taken off, the front end of the boiler packed up, and the front wheels, a x I e,. and forecarriage removed. The gearing should now be taken off -and the water tank, ash pan and firebars removed. Next pack up the boiler under the firebox, and_diseonnect and re . move the frame.

Now strip all the mountings and engine parts off the boiler.

It is very rarely necessary, however, to remove the cylinders, unless there is.something seriously wrong with them, or new jointingis needed ; all the openings should be covered up with blank covers. Replacing the cylinder correctly on the boiler is one of the most important features in erecting a wagon. The cylinder will not interfere with the repairing of the boiler. A large wooden box should be provided-for-each wagon, so that the various parts can be safely stored, instead of left knocking about on the benches or the floor ; such parts as steam and water pipes are easily damaged if not put in a place of safety. Tht parts can now be sent to the various departments for the necessary.work to be carried out. A description of typical repairs and adjustments to the various parts of the

wagon will now be described under their respective headings.

Boiler.—When a boiler comes in for general overhaul the first job is to strip off all the lagging and scrape away all the grease and dirt. It should then be thoroughly examined, as deteribed in the first article dealing with second-hand vehicles. As most boilers are insured this examination must be carried

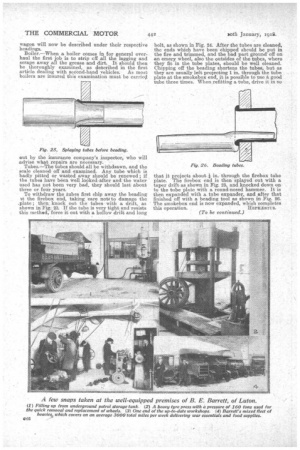

out by the insurance company's inspector, who will advise what repairs are necessary. Tubes.—The tubes should all be withdvawn, and the scale cleanedoff and examined. Any tube which is badly pitted or wasted away should be renewed ; if the tubes have been well looked after and the water used has not been very bad, they should last about three or .four years,

To withdraw the tubes first chip away the beading tt the firebox efid, taking care notf to damage the .plate ; then knock out the tubes with a drift, as shown in Fig. 23. If the tube is very tight and resists this method, force it out with a hollew clriit and long bolt, as shown in Fig. 24. After the tubes are cleaned, the ends which have been chipped should be put in the fire and trimmed, and the bad part ground off on an emery wheel, also the outsides of the tubes, where they fit in the tube plates, should be well cleaned. Chipping off the beading shortens the tubes, but as they are usually left projecting 1 in. through the tube plate at the smokebox end, it is possible to use good tube three times. When refitting a tube, drive it in so

that it projects about in, through the firebox tube plate. The firebox end is then splayed out with a taper drift as shown in Fig. 25, and knocked down on to the tube plate with a round-nosed hammer. It is then expanded with a tube expander, and after that finished off with a beading tool as shown in Fig. 28. The smokebox end is now expanded, which completes this operation. HiTiTZESTUS.