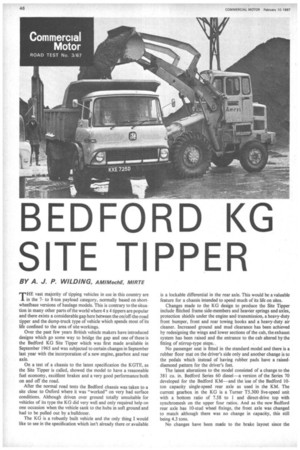

BEDFORD KG SITE TIPPER

Page 48

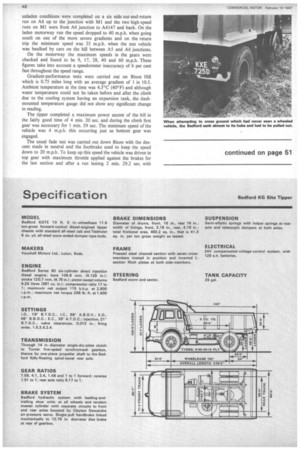

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

BY A. J. P. WILDING, AMIMechE, MIRTE

rr HE vast majority of tipping vehicles in use in this country are in the 7to 8-ton payload category, normally based on shortwheelbase versions of haulage models. This is contrary to the situation in many other parts of the world where 4 x 4 tippers are popular and there exists a considerable gap here between the on/off-the-road tipper and the dump-truck type of vehicle which spends most of its life confined to the area of site workings.

Over the past few years British vehicle makers have introduced designs which go some way to bridge the gap and one of these is the Bedford KG Site Tipper which was first made available in September 1965 and was subjected to certain changes in September last year with the incorporation of a new engine, gearbox and rear axle.

On a test of a chassis to the latest specification the KGTE, as the Site Tipper is called, showed the model to have a reasonable fuel economy, excellent brakes and a very good performance both on and off the road.

After the normal road tests the Bedford chassis was taken to a site close to Oxford where it was "worked" on very bad surface conditions. Although driven over ground totally unsuitable for vehicles of its type the KG did very well and only required help on one occasion when the vehicle sank to the hubs in soft ground and had to be pulled out by a bulldozer.

The KG is a robustly built vehicle and the only thing I would like to see in the specification which isn't already there or available is a lockable differential in the rear axle. This would be a valuable feature for a chassis intended to spend much of its life on sites.

Changes made to the KG design to produce the Site Tipper include flitched frame side-members and heavier springs and axles, protection shields under the engine and transmission, a heavy-duty front bumper, front and rear towing hooks and a heavy-duty air cleaner. Increased ground and mud clearance has been achieved by redesigning the wings and lower sections of the cab, the exhaust system has been raised and the entrance to the cab altered by the fitting of stirrup-type steps..

No passenger seat is fitted in the standard model and there is a rubber floor mat on the driver's side only and another change is to the pedals which instead of having rubber pads have a raiseddiamond pattern for the driver's feet.

The latest alterations to the model consisted of a change to the 381 cu. in. Bedford Series 60 diesel—a version of the Series 70 developed for the Bedford KM—and the use of the Bedford 10ton capacity single-speed rear axle as used in the KM. The current gearbox in the KG is a Turner T5.300 five-speed unit with a bottom ratio of 7.58 to 1 and direct-drive top with synchromesh on the upper four ratios. And as the new Bedford rear axle has 10-stud wheel fixings, the front axle was changed to match although there was no change in capacity, this still being 4.3 tons.

No changes have been made to the brake layout since the

model was introduced. This follows the Bedford TK pattern with a tandem master cylinder feeding independent hydraulic circuits to the front and rear axles and air assistance provided by a Clayton Dewandre air servo. The handbrake is linked to a disc brake at the rear of the gearbox.

The maximum gross weight rating given to the KG Site Tipper by Bedford is 26,000 lb. (11.6 tons) which is 1,000 lb. more than the two other models in the KG range—wheelbases are 12 ft. 7 in. and 13 ft. 11 in. The extra weight allowance is so that the model keeps the same nominal payload capacity of 7 tons as the other chassis in spite of the extra weight due to flitch plates, sump guard and so on.

As will be seen from the specification and results panel, the loaded test vehicle was just over its maximum gross weight with no one in the cab. The driver and passenger in the cab brought the gross weight to 7 cwt. over the Bedford maximum of 11.6 tons and even though the load of shingle in the body was evenly distributed, the front axle was carrying 10 cwt. more than its rated capacity.

The Telehoist all-steel 6 cu. yd. dumper-type body on the test chassis was heavily constructed but even so this leads one to wonder how often the KG will be operated within the Bedford front axle limit—the load was some way below the top of the body sides.

The results of this test make for interesting comparison with

those obtained on a test of a KG tipper reported in COMMERCIAL MOTOR, on June 15 1962. That example had a Bedford 330 cu. in. 98 b.h.p, diesel, a four-speed gearbox and two-speed rear axle as against the 381 Cu. in. Series 60 diesel (which produces 105 h.h.p.) and five-speed gearbox and single-speed axle.

The Site Tipper was grossing some 12 cwt. more than the earlier KG tested and the fuel consumption on normal road running was 20 per cent down, with high-speed consumption 10 per cent down. The high rear axle ratio of the 1962 test vehicle was 6.4 tol and on this test the rear axle ratio was 6.17 to 1.

Acceleration figures were very similar for the two tests and the results of the brake tests were virtually identical; brake sizes on the two vehicles were the same and slight changes made to the operating system since 1962 have obviously made up for the higher weight.

Tests of braking, acceleration and fuel consumption were carried out on and around A6 south of Luton, the brakes being checked first. Although the road was slightly damp there was a threat of rain which would have prevented usable figures being obtained. The KG behaved perfectly on the maximum-pressure stops. The only heavy marks made by the tyres were on the handbrake tests when the rear wheels locked and there were short marks from the offside tyres when these happened to be on a wet patch on one of the stops from 20 m.p.h.

Normal-speed fuel consumption tests both in the laden and unladen conditions were completed on a six mile out-and-return run on A6 up to the junction with MI and the two high-speed runs on M1 were from Ab junction to A4147 and back. On the laden motorway run the speed dropped to 40 m.p.h. when going south on one of the more severe gradients and on the return trip the minimum speed was 35 m.p.h. when the test vehicle was baulked by cars on the hill between A5 and A6 junctions.

On the motorway the maximum speeds in the gears were checked and found to be 9, 17, 28, 40 and 60 m.p.h. These figures take into account a speedometer inaccuracy of 6 per cent fast throughout the speed range.

Gradient-performance tests were carried out on Bison Hill which is 0.75 miles long with an average gradient of 1 in 10.5. Ambient temperature at the time was 4.5°C (40°F) and although water temperature could not be taken before and after the climb due to the cooling system having an expansion tank, the dashmounted temperature gauge did not show any significant change in reading.

The tipper completed a maximum power ascent of the hill in the fairly good time of 4 mm. 20 sec. and during the climb first gear was necessary for l min. 59 sec. The minimum speed of the vehicle was 4 m.p.h. this occurring just as bottom gear was engaged.

The usual fade test was carried out down Bison with the descent made in neutral and the footbrake used to keep the speed down to 20 m.p.h. To keep up this speed the vehicle was driven in top gear with maximum throttle applied against the brakes for the last section and after a run lasting 2 mm. 29.2 sec. with