CARRYING 40 PASSENGER ECONOMICALLY

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

By L. J. COTTON, M.I.R.T.E.

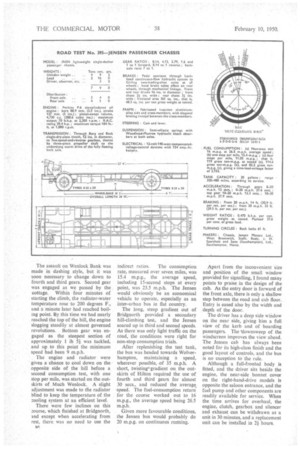

BY equipping the light-alloy passenger chassis with a Sparshatt tubular-frame body, Jensen Motors, Ltd., has produced a 40-seater bus which, because of its lightness, can be fitted with a relatively small engine without sacrificing performance. During my road test, the fuel-consumption rate with four stops per mile, and carrying a load equal to 44 passengers, was 11 m.p.g.

The Jensen passenger chassis, if it may be so termed, weighs 2 tons 12 cwt., and the unladen weight of the complete bus, ready for service, is 4 tons 91 cwt.

Worm-driven Axle The Perkins P.6 six-cylindered 4.73-litre oil engine has a power output of 70 b.h.p. at 2,200 r.p.m., and 184-lb.-ft. torque at 1,000 r.p.m. The David Brown five-speed gearbox and underslung worm-driven back axle are linked with a three-piece propeller shaft employing one Layrub and two Hardy Spicer couplings. Two self-aligning bearings support the shaft at the centre of the chassis.

Two-leading-shoe brakes of Girling pattern are actuated by a Lockheed hydraulic servo system, with a pump driven from a take-off at the rear of the gearbox. The road springs are fitted with rubber-bushed shackles and controlled by WoodheadMonroe hydraulic shock absorbers.

The frame, which is an integral chassis-cum-body structure, has cornposite 1-section members, which are fabricated of 14-gauge sheet alloy. Upper sections of the side members are 10i ins_ deep and riveted to lower B4 sections 6 ins, deep, each having 21-in, riveted flanges. The upper sections extend for the full length of the chassis. Strengthening plates are generously used.

Angle strips, riveted to the side members at the front and rear, increase rigidity, and similar strips are employed for diagonal bracing between the cross-members. The lower main-member sections extend from the rear anchorages of the front springs to the back axle. Four of the six cross-members, all of which, with the exception of the front detachable member, are of similar design, are located in line with the spring anchorages.

The body floor consists of corrugated light-alloy sheeting with flushfitting wood inserts. Both the floor and runners are integral with the main frame. The height of the wheel-arches is 61 ins, above floor level, which is 3 ft. 2 ins. above ground level.

The foundation of the body is constructed from steel tubing, the members forming the main structure being 1 ins, in diameter and of I6-gauge thickness. Tubes of 1-in, diameter are used for the roof bends and other members not subjected to the main stresses. All exterior panels, which are of aluminium, are wrapped around the tubing and pop-riveted.

The bus was collected from the Jensen works at West Bromwich and driven to Elmdon to collect the load. Travel in almost-empty buses is sometimes uncomfortable because of poor chassis suspension, but the Jensen bus has no such failing. The combination of long, soft springs and Woodhead Monroe shock absorbers is sufficient to smooth ,out all road irregularities under any condition of load.

With 23 ft. 41 ins, of body space between the driver's bulkhead and rear panel, there is almost as much space between sets as in the large underfloor-engined models.

Another good point in the Jensen is the effective insulation of the cab and saloon against engine noise. A heavy muff covers the bonnet, both in the cab and on the side projecting into the passenger entrance. In addition, the door to the saloon slides across the front bulkhead opening and effectively seals, off the engine 'from the body.

Unfortunately, this also prevents engine .heat from "reaching the interior and, seated in the saloon, I Was rather cold: I. would like some form eff,heater'to-be fitted.

After securing the 100 I-cwt.

weights on the seats, the bus was taken on the weighbridge to check the total and distributed loads. A greater proportion of the total load was being carried by the. front axle than is normal, but this did not have any direct effect on the steering.

• We left Elmdon for a preliminary canter along A5 to Shrewsbury. The heavy load reduad speed on gradients, but the gearbox and backaxle ratios were we]! matched to the , engine torque, and with five forward speeds, maximum use could be made of the engine on almost any incline.

The first consumption trial, with four stops to the mite,, was made on a 10-mile stretch between Wellington 'and Shrewsbury. Full use of the brakes was made at every stopping

point. After five miles of this treatment, wisps of smoke emerged from the brake drums, and although these increased to a cloud by the end of the trial, there was little loss of braking efficiency. The test was stopped on the outskirts of Shrewsbury, where, from the quantity of fuel required to replenish the test tank, I found the consumption rate to be 11.05 m.p.g.

After branching off the main road at Shrewsbury, I drove along A458 towards Much Wenlock. Acceleration and braking checks were made over the level " measured mile " before reaching Wenlock Bank.

Smooth Clutch Although the Jensen can be driven away from rest in third gear, it would not be advisable to do so normally, and a lower ratio was employed. It took 12 secs, to accelerate from rest to 20 m.p.h., and a further 15.6 secs. to reach 30 m.p.h. Top-gear tests were conducted without protest from the transmission, and because of the relatively low back-axle ratio, acceleration was rapid, 30 m.p.h. being reached from 10 m.p.h. in 27.9 secs.

I was not prepared for the startling effects of an emergency brake application from 30 M.p.h., when all the unsecured equipment in the saloon cannoned into the door and bulkhead. All wheels locked evenly and the bus slid forward in •a straight line for almost 10 yds. Repeat tests from the same speed and 20 m.p.h. showed that the wheels could be locked on every occasion if maximum pressure were applied on the pedal.

Because of the low atmospheric temperature (44 degrees F.), the radiator blind was adjusted during the short-stage trials to cover more than half the surface area and maintain a temperature of 184 degrees F.

The assault on Wenlock Bank was made in dashing style, but it was soon necessary to change down to fourth and third gears. Second gear was engaged as we passed by the cottage. Within four minutes of starting the climb, the radiator-water temperature rose to 200 degrees F., and a minute later had reached boiling point. By this time we had nearly reached the top of the hill, the engine slogging steadily at almost governed revolutions. Bottom gear was engaged as the steepest section of approximately I ib 51 was tackled, and up to this point the minimum speed had been 9 m.p.h.

The engine and radiator were given a chance to cool down on the opposite side of the hill before a second consumption test, with one stop per mile, was started on the out.;kirts of Much Wenlock. A slight adjustment was made to the radiator blind to keep the temperature of the zooling system at an efficient level.

There were few inclines on this :tourse, which finished at Bridgnorth. and except when accelerating from rest, there was no need to use the 136 indirect ratios. The consumption rate, measured over seven miles, was 15.4 m.p.g., the average speed, including 15-second stops at every point, was 23.5 m.p.h. The Jensen would obviously be an economical vehicle to operate, especially as an inter-urban bus in flat country.

The long, steep gradient out of Bridgnorth provided a secondary hill-climbing test, and the Jensen soared up in third and second speeds. As there was only light traffic on the road, the conditions were right for non-stop consumption trials.

After replenishing the test tank, the bus was headed towards Wolverhampton, maintaining a speed, wherever possible, of 35 m.p.h. A short, twistinegradient on the outskirts of Hilton required the use of fourth and third gears for almost 30 secs., and reduced the average speed. The fuel-consumption return for the course worked out to 16 m.p.g., the average speed being 26.5 m.p.h.

Given more favourable conditions, the Jensen bus would probably do 20 m.p.g. on continuous running. Apart from the inconvenient size and position of the small window provided for signalling, I found many points to praise in the design of the cab. As the entry door is forward of the front axle, there is only a shallow step between the road and cab floor. Entry is eased also by the width and depth of the door.

The driver has a deep side window on the near side, giving him a full view of the kerb and of • boarding passengers. The townsweep of the windscreen improves the view ahead. The Jensen cab has always been noted for its high-class finish and the good layout of controls, and the bus is no exception to the rule.

Although a full-fronted body is fitted, and the driver sits beside the engine, the near-side bonnet cover on the right-hand-drive models is opposite the saloon entrance, and the fuel pump and other components are readily available for service. When the time arrives for overhaul, the engine, clutch, gearbox and silencer and exhaust can be withdrawn as a unit in 30 minutes, and a replacement unit can be installed in 21 hours.