An Operator's View

Page 120

Page 121

If you've noticed an error in this article please click here to report it so we can fix it.

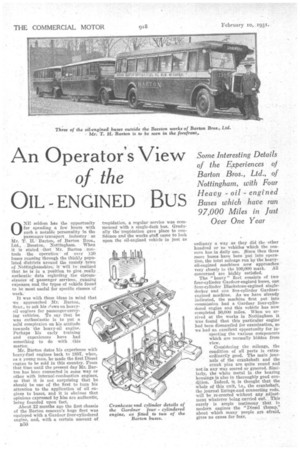

of the OIL ENGINED Bus ONE seldom has the opportunity for spending a few hours with such a notable personality in the .

passenger-transport, industry . as Mr. T. H. Barton, of Barton Eros., Ltd., Beeston, Nottingham. When it is stated that Mr. Barton controls the Operation • of over n0 buses running through the thickly populated districts around the county town of Nottinghamshire; it • will be realized that lie is in a position to give really authentic data regarding the circumstances of passenger services, running expenses and the types of vehicle found to be most useful for specific Classes of work. „

It was with these ideas in mind that we approached Mr. Barton, Senr., to ask his fiews on heavyoil -engines for passenger-carrying vehicles. To say that he was enthusiastic is to put a mild complexion on his attitude towards the heavy-oil engine. Perhaps his early training and experiences have had something to do with this matter.

Mr. Barton dates his experience with heavy-fuel engines back to 1887, when, as a young man, he made the first Diesel engine to be sold in this country. From that time until the present day Mr. Barton has been connected in some way or other with internal-combustion engines, so that it is not surprising that he should be one of the first to turn his attention to the application of oil engines to buses, and it is obvious that opinions expressed by him are authentic, being founded upon fact.

About 12 months ago the first chassis of the Barton concern's huge fleet was equipped with a Gardner four-cylindered engine, and, with a certain amount of

D50

ordinary a way as they did the -other hundred or So vehicles which the concern has in daily use. Since then three more buses have been put into operation, the total mileage run by the heavyoil-enginetl machines now approaches very closely to the 100,000 mark. All concerned are highly satisfied.

The " heavy " fleet consists of two four-cylinder Gardner-engined buses, one four-cylinder Blackstone-engined singledecker and one five-cylinder Gardnerengined machine. As we have already indicated, the machine first put into commission had a Gardner four-cylindemi engine and this vehicle has now completed 50,000 miles. When we arrived at the works in Nottingham it was found that this particular engine had been dismantled for examination, so we had an excellent opportunity for inspecting the various components which are normally hidden from view.

Considering the mileage, the condition of all parts is extraordinarily good. The main journals of the crankahaft and the crank pins are quite round and not.in any way scored or grooved. Similarly, the white metal in • the bearing housings is also in thoroughly good condition. Indeed, it. is thought that the whole of this unit, i.e., the crankshaft, the journal linings sand connecting rods, will be re-erected without any adjustment whatever being carried out. This surely is ample testimony that in modern engines the "Diesel thump," about which many people are. afraid, gives no cause for fear. All valve parts, cams, etc., are in perfect condition. Naturally the exhaustvalve seatings have become pitted a little, but from what we saw only a light skimming would be necessary in order to restore both the moving and the fixed parts of the seatings to perfect order.

Where Wear Took Place.

Only in one particular did the engine show any material signs of wear.. We refer to the cylinder bores and pistonring grooves. All five rings, by the way, of each piston were quite free in their grooves, but the top three rings had a certain amount of up-and-dawn play which, of course, is undesirable. The cylinders themselves were worn to the extent of about .015 in. at the top and approximately .008 in. at the bottom of the bores. New pistons and cylinder liners would put all this right at what must clearly be a trifling cost, considering the huge mileage over which the engine has been used.

So much for what might be termed the workshop side. We can now consider the experiences Mr. Barton has had with his fleet in service. In the first place it should be mentioned that all engines are installed in 32-seater fourwheeled vehicles, and each is geared so that when the vehicle is doing its maximum speed of 38 m.p.h. the crankshaft revolves at approximately 1,350 r.p.m. _ A typical route upon which the machines have been running is the Nottingham-Loughborough run of about 174 miles. Taking into consideration Congested areas -which have to he traversed, heavy week-end traffic and the number of villages en route, the average number of stops per mile works out at approximately three—not a high figure when compared with a central bus route in a large city, but sufficiently high a figure to illustrate that there is nothing untoward in making full use of the high torque provided by the power unit at low flywheel speeds.

Measuring Fuel Consumption.

As a contrast to the usual Diesel engineer's method of measuring the rate of fuel consumption (in lb. Per b-h-P-hour), Mr. Barton prefers the simple method used by motorists, i.e., miles per

Throughout the 50,000 miles run by the four-cylinder Gardnerengined vehicle an average of slightly more than 20 m.p.g. has been obtained— an excellent figure. On a daily total of something in the order of 250 miles, the saving in fuel alone has amounted to not less than 11, and this without any special supervision of drivers. The consumption of the five-cylindered unit is naturally not quite so good, but even this vehicle has regularly averaged 18 m.p.g. over a distance of am) miles.

The Blaekstone-engined bus has, up to the moment, completed only about 6,000 miles, and Mr. Barton feels that, although the service rendered by this vehicle has been quite satisfactory, he cannot give such authentic details as with the others—solely because it has not yet been in service long enough for him to give a considered opinion.

Starting from cold has never proved itself to be a difficult matter. By cutting ant compression on three cylinders —a simple operation on Gardner engines —the remaining cylinder does not offer sufficient resistance for the average driver to have any difficulty in cranking

over compression. Mr. Barton even went so far as to say that, if anything, the Diesel engine started more regularly at the first attempt than some of the units using petrol---another common apprehension of considerable importance laid by the heels.

Lastly, we come to the question of lubricating-oil consumption. On the latest day's run of the machine which has covered 50,000 miles, five pints of oil were used over a distance of 250 miles. This gives a consumption of 400 m.p.g. which, considering the fact that it would be the worst consumption obtained during the whole distance, is remarkably good.

The only suggestion Mx. Barton could make regarding heavy-oil engines generally is that cylinders should be lined with centrifugally east sleeves and, in• view of his experience, this would seem to be a sound suggestion as the wear of the upper portions of the cylinders, as noted in the blocks examined, might be reduced by a considerable amount.

Comment on the above does not seem to be necessary or desirable. The internal eendition of the engine was verified by ourselves, and the other facts enumerated are the result of a carefully studied examination over g long period.