MODERN METHODS OF ROAD CLEANSING.

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

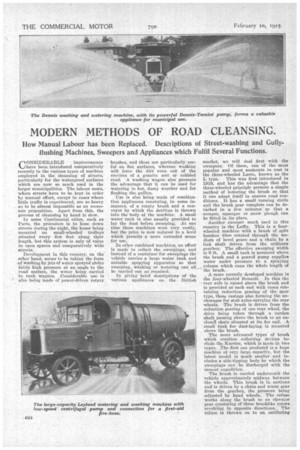

How Manual Labour has been Replaced. Descriptions of Street-washing and Gully-flushing Machines, Sweepers and Appliances which Fulfil Several Functions.

ONSIDERABLE improvements ‘.._)have been introduced comparatively recently in the various types of machine employed in the cleansing of streets, particularly for the waterproof surfaces which are now so much used in the larger municipalities. The labour costs, where streets have to be kept in order by manual effort, except in cases where little traffic is experienced, are so heavy as to be almost impossible as an economic proposition. Apart from this, the process of cleansing by hand is slow.

In some Continental cities, such as Paris, the procedure is to hose down streets during the night, the hoses being mounted on small-wheeled trolleys situated every few feet along their length, but this system is only of value in open spaces and comparatively wide streets. _

Development in this country, on the other hand, seems to be taking the form a washing by jets Of water sprayed Older fairly high pressure at an angle to the road surface, the water being carried in tank wagons. Considerable use is also being made of power-driven rotary

brushes, and these are particularly useful on fiat surfaces, whereas washing will force the dirt even out of the Crevices of a granite sett or cobbled road. A washing wagon also presents the advantage that it can be used for watering in hot, dusty weather and for flushing the. gullies.

Use is also being made of combination appliances consisting, in some instances, of a rotary brush and a conveyor by which the detritus is thrown into the body of the machine. A small water tank is also usually provided to lay the dust before sweeping. At one time these machines were very costly, but the price is now reduced to a level which permits a more extended scope for use.

In other combined machines, no effort is made to collect the sweepings; and instead of a container for sweepings the vehicle carries a 'large water _tank and suitable spraying apparatus so that sweeping, washing or watering can all be carried out as required.

In giving brief descriptions of the various applianees on the British

market, we will deal first with the sweepers. Of these, one of the most popular and most moderate in cost is the three-wheeled Lacre, known as the L type. This was first introduced in 1919, and has the advantage that the three-wheeled principle permits a simple method of lowering the brush so that it can adapt itself to uneven road conditions. It has a small turning circle and the brush gear complete can be detached in a few minutes so that a scraper, squeegee or snow plough can be fitted in its place.

Another sweeper much used in this country is the Lailly. This is a fourwheeled machine with a brush of split bamboo fibre rotated through the medium of bevel gears and a chain by a link shaft driven from the ordinary gearbox. The effective sweeping width is 6 ft. A small tank is mounted above the brush and a geared pump supplies water under pressure to a spraying column which runs the whole length of the brush.

. A more recently developed machine is the four-wheeled Renault. In this the rear axle is raised above the brush and is provided at each end with cases containing reduction gearing of the spur type, these casings also forming the anchorages for stub axles carrying the rear wheels. The brush is driven from the reduction gearing of one rear wheel, the drive being taken through a cardan shaft passing above the brush to an enclose a chain situated at its far end. A small tank for dust-laying is mounted above the brush.

The more advanced types of brush which combine collecting devices include the Karrier, which is made in two types. The first one produced is a huge machine of very large capacity, but the latest model is much smaller and includes a side-tipping body by which the sweepings can be discharged with the utmost expedition.

The brush is carried underneath the vehicle approximately midway between the wheels. This brush is in sections and is driven by a chain and worm gear from the gearbox, the pressure being adjusted by hand wheels. The refuse works along the brush to an elevator gear consisting of three brushlike rotors revolving in opposite directions. The refuse is thrown on to an oscillating

.pan 'which lifts it at frequent intervals and tips it into the rotor casing.

The Lally combined spraying, wctl. lug and sweeping machine has a tack of 700 gallons capacity, .provision being made for lifting-this-off the chassis for the fitting of an alternative type of body. A pressure and suction pump iS mounted at the rear end. This has separate control gear and is driven from the main gearbox.

A separate layshaft transmits the drive to a bevel gear in a box carried On the brush casing and thence it is conveyed to the broom spindle through a chain. The brush is mounted midway between the front and rear wheels, and gives a sweeping width of 6 ft. The controls for watering and spraying arc tueunted on the side of the driver's cab. Tile powerful jets for scouring the gullies, etc., are separately controlled.

A sweeping and watering machine is also constructed by De Dion-Boacon, Ltd. This embodies the familiar De Dion drive by eardan shafts to the rear wheels, whilst the brush drive is carried forward by a cardan shift to bevel gearing aud thence by a secondary shaft to the driving chain. Watering and washing valves are at the front, pressure being provided by a centrifugal pump, whilst the intake and flushingvalves are at the rear.

. The Renault sweeper and waterer conforms with standards laid down by the Municipality of Paris. The gearbox provides four speeds forward and drives a centrifugal pump operating the water spray. The water tank holds about 700 gallons, and the pump gives a pressure of about 36 lb. per sq. in. The width of sweep is 5 ft. 11 ins., and the brush is driven from the rear axle through carflan shafts and a chain.

It is of considerable interest to note that there is a battery eleetric brush on the market. This is the G.V. and consists of brush and gear, supplied by Jas. W. Glover and Sons, of Warwick, fitted to either the 2-.ton or 3i-ton C.V. rhassis, a small tank for a sprinkler is also provided. The brush is driven by an independent motor, and the batteries are carried on the top of the chassis instead of being unclerslung.

We, will now deal with those vehicles which cleanse by the use of water only.

Of these one of the latest and most successful is the Dennis.. This machine is of considerable interest, in that it embodies the famous Dennia-Tamini pump, this being situated at the front of the machine and driven from the front end of the crankshaft. A pump of this efficiency and capacity provides powerful jets of water which effectually scour the road surface. The pump also performs the duty of filling, the tank from natural sources of supply.

Water is delivered through machined slots in the sprinkler heads situated at each side of the Pump, each head being controlled by a separate lever. A Maximum spread of 50 ft. can be covered in one passage of the machine.

Another appliance of this type which has proved very successful is the Leyland, which is made in various types up to a capacity of 2,000 gallons, for which -the cempany's standard 10-ton forwarddash model is utilized. Machines of this type have been supplied to the Municipality of Dublin. The normal models, however, have circular tanks of 800, 1.000 or 1,200 gallons capacity, mounted on the 4-ton, 5-ton or 6-ton chassis. The pump is a low-speed centrifugal type, elmin-driven from the gearbox, and capable of filling the tank at the rate of 250 gallons per minute. Two pressure-fed sprinkler heads are mounted immediately to the rear of the driver's cab, whilst the washers consist of four fishtail nozzles working under a pressure of 30 lb. per sq. in. and set close to the ground below the near side of the machine. A valve is provided to cut off three of the four nozzles, leaving the last to flush the near-side glitter.

A special fire-hose connection provides a jet for first-aid purpose or for flushing narrow passages and streets. -For this purpose a pressure of 60 lb. is obtainable.

Two methods of fitting watering tanks are utilized by John I. Thorny croft and Co., Ltd. In one case a tank with a caPacity of 750 gallons is made interchangeable With the body of a .tip ping wagon and by using the tipping gear to lift this tank a spread of 12 ft. can be maintained. If a tipping body be not required and a fixed body is utilized, a tank of smaller capacity, with sprinkler gear attached, can be lifted into 'the body. although this method is not so satisfactory, as the spread front the Sprinkler becomes less as the tank is emptied, and suitable gear must be available for lifting the tank in and out.

The Albion Motor Car Co., Ltd„. have supplied a number of 750-gallon street sprinklers for municipal service overseas. The pressure-fed sprinkler heads On these machines are fitted at the 'tar

and give a very wide spray, which can be adjusted, as required, from the driver's seat.

In the case of the Straker-Squire road cleanser, a stream of water under pressure is followed by a .rubber squeegee which conveys the liquid material to the gullies and assists in drying the surface of the road. The tank is of 1,200-gallon capacity and the water pressure is obtained from a centrifugal pump driven by enclosed gearing. When used for washing, water is sprayed from three nozzles giving fan-shaped jets which strike the road at an angle of 45 degrees; for sprinkling only the nozzles give a spread of 45 ft.

In the Karrier washer, a single jet is utilized, pressure for this being oh

tained from a large centrifugal pump driven by chain freer' the gearbox. The spraying heads are situated behind the driver's cab and are adjustable' to any required spread.

The street-watering vehicles built by Clayton Wagons, Ltd., are usually of the combined watering and refuse-collecting type, so arranged that the tank and sprinkler gear can be dropped into the body. Ilse is' made of either the Clayton steam wagon or the Clayton electric for this purpose.

In the case of the G.V. electric, a 450-gallon tank can be used on the standard 2-ton chassis, a 750-gallon on the 31-tonner and a I,000-gallon tank on the 5-tonner. The sprinkler and flushing gears are of a patent type and can be either gravity or pressure-fed. 045