Boilers for Steam Wagons and Tractors.

Page 3

Page 4

Page 5

If you've noticed an error in this article please click here to report it so we can fix it.

(Continued from page 461.)

The question of gross weight is a very important factor in deciding the proportions of a locomotive type of boiler for a steam wagon or tractor ; it is the aim of every builder in the country to obtain the best working results with the minimum of weight.

Rule-of-thumb Methods of Design.

An analysis of the specifications of the boilers fitted to their machines by a large number of makers, however, fails to reveal any evidence of the uniform application of scientific methods for the determination of the principal dimensions. So far as the total amount of heating surface is concerned, with but one exception, the makers are practically unanimous in their acceptance of a total area varying between 63 sq. ft. and 71 sq. ft., but they differ widely in the apportionment of that total between the fire-box and the tubes. The fire-box of the boiler fitted to the five-ton Mann wagon has 18 sq. ft. of heating surface, and the tubes account for an extra 43 sq. ft., making a total of 63 sq. ft., whereas, of a total of 71 sq. ft. in the boiler of a Fritter' five-tonner, the fire-box and tubes account for 14 sq. ft. and 57 sq. ft. respectively. Yet, who will deny that both boilers are excellent steam producers, in spite of the wide differences both in the total heating surfaces and the ratio of the tube areas to plate areas? The Foster steam tractor, which is the exception named in our reference to total heating surface, has only 551 sq. ft., but the experience of the War Department, which military arm owns a large number of machines of this make, shows that it has one of the test and most-efficient boilers of the present day. All the three makers named fit feed-water heaters to their standard machines, but none of them advocates the superheating of the steam before it has done its work in the engine cylinders. An exhaust superheater, however, is fitted on the Mann wagon, but this is added with a view to the elimination of the risk of prosecution for vapour emission, and it does not add to the efficiency of the engine and boiler.

Effect of Shape on Efficiency.

It would appear, theaefore, that the general dimensions do not, except within narrow limits, govern a boiler's capacity for the production of steam, but that its shape plays a much-more-important part. A boiler with large grate area, if it be obtained at the expense of a reduction in the width of the water spaces surrounding the fire-box, is, in many cases, less efficient than one with a comparatively-small grate area, but the size of which grate permits the use of thicker water walls with their attendant improvement in circulation. Increased width of water space, too, tends to a reduction in the liability of the plates to crack. The amount of pitting, grooving and corrosion may also be reduced by this means. The Foden boiler is a case in point. It has but 21sq. ft. of grate area, as against most other maker's 3 sq. ft. ar over. Mann's fire grate, whilst of more-generous proportions than that of the Foden wagon, has only 2.7 eq. ft., but it is generally admitted that bath these makes are thoroughly practical and efficient.

Size of Smoke-box.

There is a wide divergence of opinion, amongst wagon and tractor makers, as to the best volumetric size far a smoke-box, and, from information before us, we find that these vary from 31. cubic ft. up to 71 cubic ft. When the builder of the wagon with the 31-cubic-feet smoke-box decided on that size, it is evident that the exigencies of design of the machine as a whole had more influence than considerations for the thermal efficiency of the boiler. Too often, the smoke-box is regarded merely as a chamber in which the furnace gases are collected, after their passage through the smoke-tubes, before the final emission of the products of combustion into the atmosphere. As a matter of fact, the size of the smoke-box has a most-important bearing on the boiler's thermal efficiency. The smokeboxes should neither be so small that the temperature of the spent gases is abnormally high, nor so low that the gases extract heat from the front tube-plate. High velocities and spasmodic bleats of more-or-less spent gases

from the furnace quickly lead to the choking-up of the smoke-tubes with coal or coke dust and cinders, and the necessity for frequent applications ol the tube brush.

Working Level of Water.

On the two questions of the working level of the water above the fire-box crown and the ratio of steam space to water space, all makers of locomotive-type boilers of wagons and tractors appear to be in agreement that 4 in. of water above the crown, when standing on a level surface, is a reasonable amount, and that fur each cubic ft. of steam space there should be just over two of water.

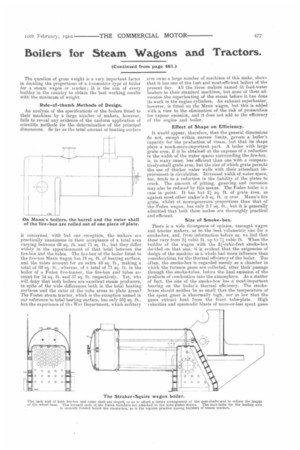

We have already, in cur issue of the 27th ult., given two diagrams of typical locomotive-type boilers for steam wagons and tractors, but, before proceeding briefly to describe a few boilers which are modifications of the locomotive type, we would direct attention to one of the accompanying sketches, which shows how, in a Mann boiler, the outer fire-box plate and the barrel are rolled out of one piece, thus avoiding a joint, which the ordinary form of construction necessitates, between the barrel and the wrapper plate. A cleaner joint for the throat plate is also secured by this method of construction; as there are fewer joints, there is also less tendency for the occurrence of grooving of the plates, and especially so as all the bends are of easy radius.

Modifications of the Locomotive Type.

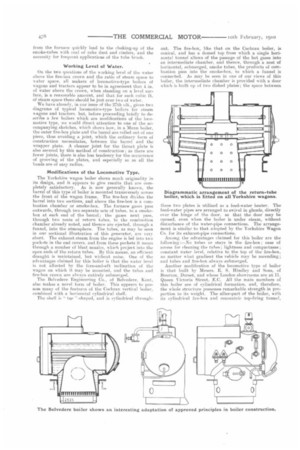

The Yorkshire wagon boiler shows much originality in its design, and it appears to give results that are completely satisfactory. As is now generally known, the barrel of this type of boiler is mounted transversely across the front of the wagon frame. The fire-box divides the barrel into two sections, and above the fire-box is a combustion chamber or smoke-box. The furnace gases pass outwards, through two separate sets of tubes, to a smokebox at each end of the barrel; the gases next pass, through two nests of return tobes, to the combustion chamber already noted, and thence are ejected, through a funnel, into the atmosphere. The tubes, as may be seen in our sectional illustration of this generator, are very short. The exhaust steam from the engine is led into two pockets in the end covers, and from these pockets it issues through a number of blast nozzles, whieh project into the open ends of the return tubes. By this means, an efficient draught is maintained, but without noise. One of the advantages claimed for this boiler is that the water level is not affected by the fore-and-aft inclination of the wagon on which it may be mounted, and the tubes and fire-box crown are always entirely submerged.

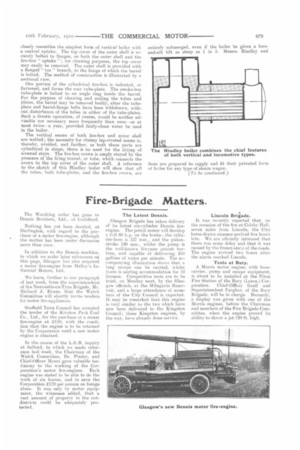

The Belvedere Engineering Co., of Belvedere. Kent, also makes a novel form of boiler. This appears to possess many of the features of the Cochran vertical boiler, combined with a horizontal cylindrical shell.

The shell is " tee "-shaped, and is cylindrical through

out. The fire-box, like that on the Cochran boiler, is conical, and has a domed top from which a single horizontal tunnel allows of the passage of the hot gases into an intermediate chamber, and thence, through a nest of horizontal, submerged, smoke tubes, the products of combustion pass into the smoke-box, to which a funnel is connected. As may be seen in one of our views of this boiler, the intermediate chamber is provided with a door which is built up of two dished plates ; the space between these two plates is utilized as a feed-water heater. The feed-water pipes are arranged to swivel in glands, directly over the hinge of the door, so that the door may be opened, even when the boiler is under steam, without disturbance of the water-pipe connections. The arrangement is similar to that adopted by the Yorkshire Wagon Co. for its exhaust-pipe connections. Among the advantages claimed for this boiler are the following:—No tubes or stays in the fire-box; ease of access for cleaning the tubes; lightness and compactness; constant water level, relative to the top of the fire-box, no matter what gradient the vehicle may be ascending; and tubes and fire-box always submerged.

Another modification of the locomotive type of boiler is that built by Messrs. K S. Hindley and Sons, of Bourton, Dorset, and whose -London showrooms are at Queen Victoria Street, E.C. All the main members of tins boiler are of cylindrical formation, and, therefore, the whole structure possesses remarkable strength in proportion to its weight. The after-part of the boiler, with its cylindrical fire-box and concentric top-firing tunnel,

closely resembles the simplest form of vertical boiler with a central uptake. The top cover of the outer shell is securely bolted to flanges, on both the outer shell and the fire-box " uptake " ; for cleaning purposes, the top cover may easily be removed. The outer shell is provided with a flanged " tee " branch, to the flange of which the barrel is bolted. The method of construction is illustrated by a sectional view.

One portion of the cylindrical fire-box is indented, or flattened, and forme the rear tube-plate. The smcke-box tube-plate is bolted to an angle ring inside the barrel. For the purpose of cleaning and scaling the tubes and plates, the barrel may be removed bodily, after the tubeplate and barrel-flange bolts have been withdrawn, without disturbance of the tubes in either of the tube-plates. Such a drastic operation, of course, would be neither advisable nor necessary more frequently than ones—or at most twice—a year, provided fairly-clean water be used in the boiler.

The vertical seams of both fire-box and outer shell are welded; the necessity for clumsy lap-riveted seams is, thereby, avoided, and further, as both these parts are cylindrical in shape, there is no need for the fitting of screwed stays. The fire-box crown is amply stayed by the presence of the firing tunnel, or tube, which connects the crown to the top cover of the outer shell. A reference to the sketch of this Hindley boiler will show that all the tubes, both tube-plates, and the fire-box crown, are entirely submerged, even if the boiler be given a foreand-aft tilt as steep as 1 in 3. Messrs. Hindley and Sons are prepared to supply and fit their patented form of boiler for any type of steam wagon.

(To be continued.)