DEMOUNTABLE

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

DISTRIBUTION -4

by Alan Bunting, MIMechE

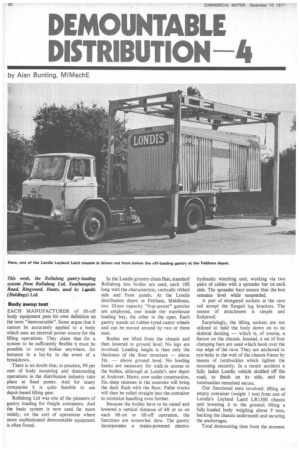

This week, the Rol!along gantry loading system from Rollalong Ltd, Southampton Road, Ringwood, Hants, used by Low& (Holdings) Ltd.

Body swop test EACH MANUFACTURER of lift-off body equipment puts his own definition on the term "demountable". Some argue that it cannot be accurately applied to a body which uses an external power source for the lifting operations. They claim that for a system to be sufficiently flexible it must be possible to swop bodies anywhere, for instance in a lay-by in the event of a breakdown.

There is no doubt that, in practice, 99 per cent of body mounting and demounting operations in the distribution industry take place at fixed points. And for many companies it is quite feasible to use depot-based lifting gear.

Rollalong Ltd was one of the pioneers of gantry loading for freight containers. And the basic system is now used far more widely, on the sort of operations where more sophisticated demountable equipment is often found. In the Londis grocery chain fleet, standard Rollalong box bodies are used, each 18ft long with the characteristic, vertically ribbed side and front panels. At the Londis distribution depot at Feltham, Middlesex, two 10-ton capacity "four-poster" gantries are employed, one inside the warehouse loading bay, the other in the open. Each gantry stands on rubber-tyred castor wheels and can be moved around by two or three men.

Bodies are lifted from the chassis and then lowered to ground level. No legs are involved. Loading height is then only the thickness of the floor structure — about 51n. — above ground level. No loading banks are necessary for walk-in access to the bodies, although at Londis's new depot at Andover, Hants, now under construction, Sin.-deep recesses in the concrete will bring the deck flush with the floor. Pallet trucks will then be rolled straight into the container to minimize handling even further.

Because the bodies have to be raised and lowered a vertical distance of 4ft or so on each lift-on or lift-off operation, the functions are somewhat slow. The gantry incorporates a mains-powered electro

hydraulic winching unit, working via two pairs of cables with a spreader bar on each side. The spreader bars ensure that the box remains level while suspended.

A pair or elongated sockets in the rave rail accept the flanged lug brackets. The means of attachment is simple and foolproof.

Surprisingly, the lifting sockets are not utilized to hold the body down on to its skeletal decking — which is, of course, a fixture on the chassis. Instead, a set of four clamping bars are used which hook over the top edge of the rave. They are anchored to eye-bolts in the web of the chassis frame by means of turnbuckles which tighten the mounting securely. In a recent accident a fully laden Londis vehicle skidded off the road, to finish on its side, and the turnbuckles remained secure.

Our functional tests involved: lifting an empty container (weight I ton) from one of Londis's Leyland Laird LR1300 chassis and lowering it to the ground; lifting a fully loaded body weighing about 9 tons, backing the chassis underneath and securing the anchorages.

Total demounting time from the moment the vehicle stopped below the gantry was 2min 25sec. The laden container was picked up and secured in 3min 25sec.

There was no difficulty in getting the body and chassis aligned. The suspended container could be eased fore-and-aft or transversely by hand to correct misalignments of one or two inches.

Service experience

Londis has nine chassis. all Leyland Laird or Boxer 13 tons gvw models, working with 18 containers. The Feltham warehouse is designed with a floor-level loading area which can accommodate all nine boxes. Normally, three "gangs" of men with at least one man packing and one checking — are kept fully employed during normal working hours loading the bodies.

Londis's transport and warehousing manager, Mr Harry Fuller, says one of the greatest benefits of the Rol!along equipment is the facility of ground level loading. A container can be fully loaded in an hour,

with two men. On the company's older fixed-bodied vans tail-lifts are used in conjunction with wheeled-baskets. The same number of cases of provisions need well over two hours for loading. Elimination of the case, or stillage, handling has also substantially reduced the checking procedure. Because the older vehicles' tail-lifts were hydraulically powered from a gearbox No, the engine had to be kept running. Average fusel consumption per vehicle has now been reduced by 15 gallons a week — equivalent to an improvement from 8 to 11 mpg.

When the Andover depot and another one at Erith, Kent, are in full operation, it is planned that the warehouse "pickers" (or consignment assemblers) will use pallet trucks, as described earlier, and also stack the boxes in the waiting containers.

All the delivery rounds — to small grocery shops who are members and therefore shareholders of the Londis group are usually scheduled to occupy a full day's working for one vehicle. But, occasionally, vans are sent out twice in a day and rapid turnround times of no more than 10 minutes can be achieved.

Mr Fuller's criticisms of the Rollalong system are few. He concedes that the floor level is high for shop-to-shop deliveries. But many of the cases and boxes can be offloaded on to the higher level of' a pavement, via the nearside roller shutter included in all the containers.

Next week: body change by Arlington Bodybuilders Ltd.