USG's fwd low loader on the road

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

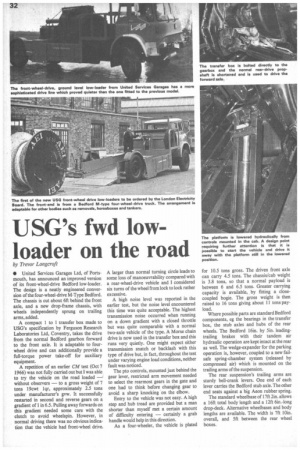

by Trevor Longcroft • United Services Garages Ltd, of Portsmouth, has announced an improved version of its front-wheel-drive Bedford low-loader. The design is a neatly engineered conversion of the four-wheel-drive M-Type Bedford. The chassis is cut about 6ft behind the front axle, and a new drop-frame chassis, with wheels independently sprung on trailing arms, added.

A compact 1 to 1 transfer box made to USG's specification by Ferguson Research Laboratories Ltd, Coventry, takes the drive from the normal Bedford gearbox forward to the front axle. It is adaptable to fourwheel drive and can additionally provide a full-torque power take-off for auxiliary equipment.

A repetition of an earlier CM test (Oct 7 1966) was not fully carried out but I was able to try the vehicle on the road loaded — without observers — to a gross weight of 7 tons 19cwt lqr, approximately 2.5 tons under manufacturer's gvw. It successfully restarted in second and reverse gears on a gradient of 1 in 6.5. Pulling away forwards on this gradient needed some care with the clutch to avoid wheelspin. However, in normal driving there was no obvious indication that the vehicle had front-wheel drive. A larger than normal turning circle leads to some loss of manoeuvrability compared with a rear-wheel-drive vehicle and I considered six turns of the wheel from lock to lock rather excessive.

A high noise level was reported in the earlier test, but the noise level encountered this time was quite acceptable. The highest transmission noise occurred when running on a down gradient with a closed throttle but was quite comparable with a normal two-axle vehicle of the type. A Morse chain drive is now used in the transfer box and this runs very quietly. One might expect either transmission snatch or backlash with this type of drive but, in fact, throughout the test under varying engine load conditions, neither fault was noticed.

The pto controls, mounted just behind the gear lever, restricted arm movement needed to select the rearmost gears in the gate and one had to think before changing gear to avoid a sharp knocking on the elbow.

Entry to the vehicle was not easy. A high step and hub tread are provided but a man shorter than myself met a certain amount of difficulty entering — certainly a grab handle would help in this direction.

As a four-wheeler, the vehicle is plated for 10.5 tons gross. The driven front axle can carry 4.5 tons. The chassis/cab weight is 3.8 tons, so that a normal payload is between 6 and 6.5 tons. Greater carrying capacity is available, by fitting a closecoupled bogie. The gross weight is then raised to 16 tons giving about 11 tons payload.

Where possible parts are standard Bedford components, eg the bearings in the transfer box, the stub axles and hubs of the rear wheels. The Bedford 16in. by 5in. leadingtrailing brakes with their tandem air hydraulic operation are kept intact at the rear as well. The wedge-expander for the parking operation is, however, coupled to a new failsafe spring-chamber system (released by compressed air) which is mounted on the trailing arms of the suspension.

The rear suspension's trailing arms are sturdy bell-crank levers. One end of each lever carries the Bedford stub axle. The other end seats against a big Aeon rubber spring.

The standard wheelbase of 17ft 2in. allows a 16ft total body length and a 12ft 6in.-long drop-deck. Alternative wheelbases and body lengths are available. The width is 7ft 10in. overall, and 5ft between the rear wheel boxes.