Distributor Pumps the Next Step?

Page 58

Page 59

Page 60

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

Few Designs Have Yet Proved Successful in Practice, but Makers Throughout the World Strive On

Suggestions for distributor-pump designs have been recorded since the earliest days of the compressionignition engine, but little or no success has been obtained with them until recently. Improvements in manufacturing techniques and the development of new materials have now brightened the outlook considerably, but the demands made on the fuel-injection pump by engine needs are ever increasing.

Certain designs of pump provide the only apparent answer to higher engine speeds and more exacting _ combustion requirements, but they do not seem to offer the degree of simplicity that most operators would desire.

Before considering the future of this type of pump it a24 the outlets can be more widely spaced. This valve is also less likely to seizethan were it merely rotating.

Another type employing a conventional helix-control pumping unit feeds fuel to a common gallery. Camactuated poppet_ valves then release the fuel to the appropriate cylinders. Major advantages of the separate plunger system are that normal injection characteristics are obtained . and components used for the pumping portion can be of the same design as those used in multi-plunger pumps.

The integral pump and distributor unit combines the two functions of pumping and distributing. Usually, a single plunger is reciprocated to pump, which, at the same time, is rotated to distribute. Fig. 6 illustrates this principle in a .design patented in 1951 by C.A.V. Ltd., and Fig. 7C shows the plunger.

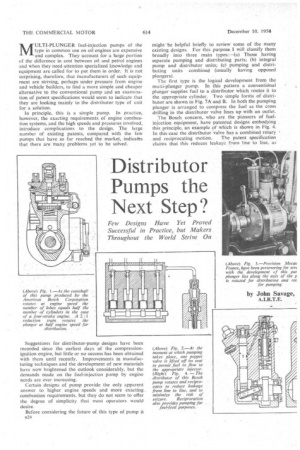

A pump, similar in principle, was produced in large quantities, about six years ago, by the American Bosch Corporation. More recently they introduced a modified version (Fig. 1). The method of varying the quantity of fuel delivered by this pump is interesting, as if has a wide application to both distributor and multi-plunger_ pumps.

A block, lapped to the plunger and held in place by a linkage connected to the governor, prevents fuel from flowing out of a groove in the plunger. Upward movement of the plunger eventually causes the groove to emerge from the block, allowing fuel to escape. The fuel pressure then drops and pumping ceases. By varying the position of the block the quantity of fuel delivered is controlled.

The Mono-cam pump, which was fully described in The Commercial Motor on July 9, employs this method of control. This is a single-cam multi-plunger pump.

Coming within the second classification is a unit produced by Le Precision Wcanique, France, which is now being used on Panhard oil engines. In this pump the rotational movement required for distributing is obtained directly from the pump drive. The reciprocation for pumping occurs When rollers, carried on arms extended fr.om the plungers, run up the babes of a face cam.

One of the earliest ideas for a distributor pump was developed by Hesslernan in Sweden. It had four individual helix sections disposed ofe above the other on one plunger. A cam, with four successive steps and one quick return stroke, was used. Distribution of the fuel was found to be uneven and the cam design imposed very severe limitations on the maximum speed. Generally, the integral pumps are now of the type in which a single plunger is reciprocated for pumping, and rotated for distributing.

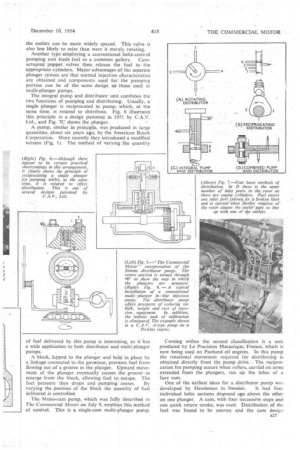

When pumping and distributing units are combined, the distributor is rotated and fuel is successively ejected out of radial outlets, but pumping is done in a different way. Two opposed plungers are carried in the rotating distributor valve, at right-angles to the axis of the valve (Fig. 7D).

Small roller-tappets ,at the outer end of each plunger run within an internal cam ring. When the rollers reach the cam lobes the two plungers are squeezed together. Fuel, previously trapped between them, is forced out of one of the radial outlets.' Fuel is supplied to the plungers by a low-pressure feed pump, through drillings in the rotating distributor.

A pump employing this principle is being developed by the American Bosch Corporation, and in this country by Simms Motor Units, Ltd. -Another American concern, the Hartford Machine Screw Co., are already in production with a pump, of this type.

Detail Differences

Although the principle of pumping and distributing is basically similar, there is a number of detailed differences' between the Simms-A.B.C. design, which was shown at this year's Commercial Motor Show (Fig. 5), and the Hartford pump, which was described in a paper presented to the Society of Automotive Engineers in January, 1953, and printed in the S.A.E. Journal in June of that year.

Another system that must be mentioned is the lowpressure type in which metered fuel is delivered to a combined pump and injector in each cylinder. This system has-been favoured by the Cummins Engineering Co., Inc., in the past, but has now been superseded by their latest development.

This new system relies on a single gear-type pump to feed fuel at low variable pressures through a common manifold to a combined pump and injector unit in each cylinder. The quantity of fuel injected is determined by the fuel pressure and the period during which an orifice in the injector is open. This is a common supply system—nota distributor type—and its merits should be compared with those of other combined pump and injection systems, rather than with those of distributor pumps.

Keeping Down Costs

Theoretically, the main virtue of all distributor pumps lies in the easy application of a basically similar pump to a variety of engines. This feature, coupled with the fact that special characteristics for any one application can be obtained by using many standard parts in conjunction with a few special components, should help to keep down manufacturing costs.

It is their flexibility, together with the prospect of mass-producing standard components at slightly lower manufacturing costs, that has probably promoted the interest shown in distributor pumps. This is a general consideration, without regard to the actual design of the pump.

When it comes to determining the relative merits of particular designs, there seems to be a market for two distinct types. One would be for a small, cheap, simple pump for use on engines having a maxima-in speed of about 2,000 r.p.m. These would include the small and medium-sized engines used for tractors, goods vehicles and industrial applications. The second market would be for the high-speed engine which will be used when performance is more important than first cost.

ai6 I believe that in the first market the conventional multi-plunger pump is likely to hold its own for a long 'time. There is room for simplification and cost saving and a step in this direction has been taken by Scintilla, Ltd., who are experimenting with a multi-plunger pump which is conventional in most respects, but is only 8 in. long and weighs 6 lb. It is suitable for engines up to 2+ litres with a maximum of 3,000 r.p.m.

If distributor puMps are to compete with this type of pump they will have to be cheap, simple, reliable and have a long life. I doubt their ability to meet all these requirements; but they certainly do have one outstanding advantage, in that the output for each line should be nominally the same without resorting to lengthy setting and calibration. .

There is little .doubt, however, that the distributor pump presents a better answer to the requirements of the high-performance oil engines than the conventional pump, and in the interests of standardization they may eventually be applied to all oil engines.

The high speed and the high rate of injection that engines of the futnre are likely to employ, especially if they are of the two-stroke type, reject all types of pump, distributor or multi-plunger, in which any form of heavily spring-loaded cam follower is employed. High engine speeds, small deliveries and high rates of injection will call for steep cam forms and heavy springs to prevent tappet bounce.

This would result in heavier and more complicated units when small lightweight equipment is needed. This may well explain why the American Bosch Corporation ceased production of their early design of distributor pump and are now working on the type with opposed plungers. The cam followers, in this type,"can be very light and need not be spring-loaded, and high pump speeds can be accommodated.

Another small but important point to consider is that all pumps having radially disposed outlets introduce fuel-delivery-pipe probrems.

One of the simplest pipe systems that can be obtained when radial outlets are used is achieved by mounting the pump vertically. The opposed-plunger type lends itself to this method of mounting, although there are other solutions of the prOblem, as can be seen in Fig. 3, in which a method of piping adopted by Le Precision Mecanique, France, is shown.

Fuel-injection equipment will keep pace with oilengine progress, but the operator who is mainly interested in low initial cost, easy maintenance and cheap replacements, may be a little disappointed if he expects the distributor pump to be the panacea of all injection pump troubles. The highest standard of precision engineering is called for in all the distributortype pumps known to be in the course of development.

This indicates that the same care and specialized attention required with existing multi-plunger pumps

will still be needed. Fuel filtration will be most important, as the quantity of fuel passing through the• unit will be the total quantity consumed by the engine,

and not merely that supplied to one cylinder as is the case with multi-plunger pumps.. The recent introduction of paper-element filters may solve this Problem.

For cheap power units, a completely pumpless engine may he the solution, but, so far, too little effort has been exerted on the development of these units to make them a practical proposition. In the meantime, a slightly increasing use of distributor pumps can be expected. It will be compelled partly by the changing requirements of the high-speed oil engine, and partly by the desire for standardization