Unique Test of a Scammell Six-wheeler for Germany

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

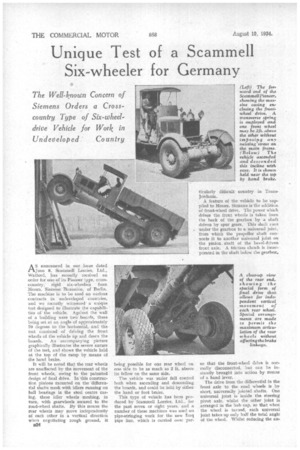

As announced in our issue dated June 8, Scammell Lorries, Ltd., Watford, has recently received an order for one of its Pioneer type, crosscountry, rigid six-wheelers from Messrs. Siemens Bauunion, of Berlin. The machine is to be used on various contracts in undeveloped countries, and we recently witnessed a unique test designed to illustrate the capabilities of the vehicle. Against the wall of a building were two boards, these being set at an angle of approximately 70 degrees to the horizontal, and the test consisted of driving the front wheels of the vehicle up and down the boards. An accompanying picture graphically illustrates the severe nature of the test, and shows the vehicle held at the top of the ramp by means of the hand brake.

It will be noted that the rear wheels are unaffected by the movement of the front wheels, owing to the patented design of final drive. In this construction pinions mounted on the differential shafts mesh with idlers running on ball bearings in the steel centre casing, these idler wheels meshing, in turn, with gearwheels secured to the road-wheel shafts. By this means the rear wheels may move independently of each other in a vertical direction when negotiating rough ground, it 824 being possible for one rear wheel on one side to be as much as 2 ft. above its fellow on the same side.

The vehicle was under full control both when ascending and descending the boards, and could be held by either the hand or foot brake.

This type of vehicle has been produced by Scammell Lorries, Ltd., for the past seven or eight years, and a number of these machines was used on pipe-stringing work for the new Iraq pipe line, which is carried over par

ticularly difficult country in TransJordania.

• A feature of the vehicle to be supplied to Messrs. Siemens is the addition of front-wheel drive. The power which drives the front wheels is taken from the back of the gearbox by a shaft driven by spur gears. This shaft runs under the gearbox to a universal joint, from which the propeller shaft connects it to another universal joint on the pinion, shaft of the bevel-driven front axle. A friction clutch is incorporated in the shaft below the gearbox, so that the front-wheel drive is normally disconnected, but can be instantly brought into action by means of a hand lever.

The drive from the differential in the front axle to the road wheels is by short, universally jointed shafts. One universal joint is inside the steering pivot axle, whilst the other joint is arranged in the hub cap, so that when the wheel is turned, each universal joint takes up only half the total angle of the wheel. Whilst reducing the an guIarity of the joints, this also has the, effect of cancelling out the irregularities in angular velocity ratio which arise on vehicles in which only one universal joint is employed. By this means the drive to each front wheel is at all times uniform, and front-wheel slip under severe conditions is much less likely to occur.

The vehicle is fitted with a standard Scammell four-cylindered engine rated at 40 h:p. With a bore of 5 ins, and a stroke of 5i ins,, a maximum of 85 b.h.p is developed.

The machine is equipped with a fivespeed gearbox, the overall gear ratios being: top, 13.5 to 1; fourth, 23.6 to 1; third, 36.5 to 1; second, 68.7 to 1; first and reverse,. 140.0 to 1.

The brake pedal operates internalexpanding shoes in a ribbed drum at the back of the gearbox, and a hand lever operates internal-expanding brakes on all four rear wheels. There

is, in addition, a short lever which Can be used to hold the transmission brake in the " on" position when restarting from rest on an extremely severe gradient. This lever requires less force for its operation than the ordinary hand-brake lever, and the arrangement has the advantage that if the driver be late in releasing the brake when starting on his emergency gear, no excessive stresses' are set up in the rearaxle transmission,