Hot competition in a cold market

Page 64

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

BRITISH operators of refrigerated vehicles have a wide selection of refrigerating equipment that they can specify. As well as mechanical units available from a number of companies there are liquid-gas and solid-gas types—liquid nitrogen and liquid carbon dioxide and solid carbon dioxide (dry ice), and while there has been little recent change in the latter fields there have been developments in.mechanical refrigeration. More companies have entered the market, mainly with units for smaller vehicles, while others have dropped out.

This article gives the current situation. It details the latest developments, systems and types of unit now available to the operator. Where performance details are given the basis is Odeg F box temperature and 100deg F ambient unless stated otherwise.

Mechanical refrigeration equipment THE longest-established name in this field in Britain is Thermo-King, refrigeration units being manufactured and marketed by Petters Ltd, Hamble, Southampton. But competition has increased in the past year with Locomotors Ltd, of Andover, now concessionaire for the American Weathertrol units, Hubbard Engineering Co Ltd, of Martlesham, Woodbridge, Suffolk, now in production with a useful range, and the Frigiking Division of Cummins Engine Co Ltd, which has just reappraised its position and is obviously looking for a bigger share of the market.

The popularity of Winget-Dole hold-over plates from Winget Ltd, Rochester, Kent, continues, especially for local delivery work in conjunction with refrigeration units from firms such as Prestcold, Frigidaire and the York Division of Borg-Warner Ltd. Petters has equipment specially designed for use with containers and so has Prestcold while J. and E. Hall Products, Dartford, Kent, has a unit designed for easy connection to and disconnection from containers and another that "plugs in" to containers.

Latest developments by Petters are hydraulically driven units, models for small delivery vehicles, the PT lightweight over-cab unit and the container equipment already referred to. The hydraulically driven model is the HM 20D and this can be driven from a power take-off mounted either at the front end of the engine or from the gearbox of the vehicle.

Electric-motor drive is also incorporated as well as reverse-cycle defrost and the model is available for•12V or 24V systems. Refrigeration capacity is 5500 btu/hr. This figure applies also to the PetterrM Series on which the HM is based. There are, in all, nine M models including petrol or propane engined, electric-motor driven and LC. engine/electric types. Standard models have reverse-cycle defrost but there are hot-gas defrost versions also.

The PT is a larger capacity self-contained refrigeration unit with 8000 btu. It is available with petrol or propane engine drive (PT 10) or with an electric motor for use when stationary as well (PT 20) and in both cases there is automatic defrost.

The Slimline unit for containers is electrically driven and is designed for fitting in a recess in the front of a container. It has a capacity of 6000 or 7000 btu/hr according to the electrical supply and overall dimensions are 3f1 6in. wide by 6ft 6.5in. high by 12.5in. deep for the condenser section; the evaporator section which goes inside the body measures 3ft 5.5in. by 4ft 2.2in. by 12in. deep.

For medium-size vehicles Petters has the PA and HPA, the latter being an hydraulicdrive version used in conjunction with an engine or gearbox power take-off. In all cases capacity is 4,460 btuihr and the PA is offered with petrol or propane engine drive, electric motor drive or both and the HPA comes with the straightforward hydraulic drive or with electric motor drive added.

For light vehicles

A skirt-mounted condenser is standard for the TG 10 which Petters offers for light delivery vehicles but a roof-mounted model is available as an alternative. The compressor for the refrigeration equipment is driven from the vehicle engine, the condenser unit is a separate unit (for mounting on the side of the body or above the cab) and the evaporator unit is mounted inside the body. The thermostat is adjustable for a box tempera

ture from 35deg F to 45deg F.

A new development by Hubbard Engineering is the availability of the 1100 unit for large trucks and semi-trailers with power supplied by a Perkins 4A08 diesel engine. Hubbard couples the engine to a three-phase alternator which provides 380 to 440V power for the electric refrigeration section. Petrol or propane engine drive continues to be available and the power section is intended to be located beneath the body with the refrigeration unit mounted in the upper part of the body front. The refrigeration section can obviously be operated from a suitable external supply when the vehicle is not on the road and with a capacity of up to 11,500 btu/hr the unit is suitable for maximum-size bodies—up to 40ft long.

Hubbard has been active in the transport refrigeration market for less than 18 months , and its first model—the 400—is reported to be well established. This is designed for vans and light trucks of up to about 450 cult.; capacity is 3400 btu/hr. There are four basic versions providing for operation at either 35deg F or Odeg F, with the option in each case of a stand-by unit for overnight cooling. The compressor is driven from the engine with the condenser above the cab and the evaporator in side the body. Withthe electrical stand-by option the necessary equipment is fitted in the skirt of the vehicle.

Weathertrol units from Locomotors include both combined units for bigger vehicles and models where the components are separated. There are altogether six models which give capacities from 4500 btu/hr to 7500 btu/hr. In all except one case the compressor is driven from the engine, the exception being the GNE where there is petrolengine drive for the combined refrigeration unit. This is the model with the highest capacity. It is also supplied with an electric stand-by facility.

Next in size are the Weathertrol A2M and A2E. These are basically the same design but the latter can be powered from a threephase mains supply when standing. Capacity is 5000 btu/hr and the condenser and evaporator are in both cases combined for Yarn of body mounting. The compressor of the A2M is driven from the vehicle engine and from a gearbox power take-off on the A2E.

In the ease of the D9 and D9E condenser and evaporator are separate. These two are also basically the same with the D9E having equipment for operation from the mains—a normal single-phase supply. Capacity of each is 4500 btu/hr.

The sixth Weathertrol unit is the D1OE which has a separate evaporator and condenser and a capacity of 4500 btu/hr. The compressor can be driven from the engine or transmission of the vehicle and this model can also be powered from a single-phase mains supply.

New development The new development by Frigiking consist of the appointment of three main distributors to cover the UK and they will sell three basic refrigeration units. These are primarily designed for use in light and medium-duty delivery vans with body lengths of up to 14ft although obviously they will be suitable for bigger bodies in particular circumstances. The three units are the 720, 730 and 740 and in each case the compressor is driven from the engine or gearbox power take-off. There are four types of Frigiking 720, the EH being designed for use at 35deg F, the EL down to Odeg F and the H and L, the same models respectively but without electrical stand-by equipment. The

equipment gives a capacity of 2700 btu/hr when on the road and 1000 btu/hr on stand-by.

The Frigiking 730 follows the general design of the 720 but is only available for retaining a 35deg F body temperature. Capacity at this temperature in an ambient of 100deg F is 6500 btu/hr. Whereas with the 720 the condenser is mounted above the cab and the stand-by unit in a convenient location, the 730 condenser/stand-by unit is designed for mounting low down on the van body below floor level. The 740 is similar to the 730 in all respects except that the condenser/stand-by unit is mounted on the front bulkhead of the body above the cab.

There are two basic refrigeration units for containers available from J. and E. Hall, the Isoplug and Isoclip. Both are supplied generally for coupling to a three-phase supply for powering the compressor and fans. The Isoclip fits to the front end of the container into the ISO corner brackets with a quick-release attachment. Cold air fed into the cargo space goes through a 10in. hole low in the front wall and is returned to the unit through a second aperture at higher level. An advantage in the use of the Isoclip is the ease with which it can be disconnected for servicing. When used on road transport power would have to be obtained from an engine-driven generator mounted on the vehicle chassis.

The Isoplug is similar in general concept but fits into a recess in the front of the container—as a plug-in attachment—and makes a flanged connection flush with the end wall; it can be removed easily for servicing.

In the case of a model designed for use in a 20ft container, capacity of the Isoplug is 12,400 btu/hr while the Isoclip gives 8600 btu/hr on the same basis. Depth of the 'sipping is 16in. while the Isoclip projects 19in. and equipment for 30ft and 40ft containers can also be supplied.

Winget-Dole hold-over plates continue in popularity no doubt because they are reliable, simple to install and to maintain. The plates are made in different thicknesses and in a number of standard sizes to fit the majority of vehicle bodies. In use they are connected to a standard refrigerating system to solidify the eutectic solution in them.

Standard solutions used by Winget have melting points between — 12deg F and + 26 deg F and the solution absorbs heat for a long period of time. Recharging the plates at the depot is satisfactory for many uses where the cycle of operation is fixed but on some applications where the compressor is carried on the vehicle it can be operated by a power take-off and thinner plates used, the holdover feature being needed only in an emergency.

Winget-Dole plates are sometimes used as shelves in low-temperature bodies and the company's Truk-Cel unit is said to be popular now. This combines hold-over plates with a fan unit and is said to be ideal for use with vehicles carrying such things as dairy produce as a constant temperature can be maintained throughout the load in the range of 38 to 45deg F.

Solid carbon dioxide THIS refrigerant—known as dry ice—is favoured by many companies because it is simple, inexpensive to operate and initial cost is low. Some control over temperature can be obtained by carrying the "dry ice" in compartments where the degree of evaporation and hence the cooling effect can be regulated. Two companies market dry ice. ICI Ltd, Agricultural Division, calls it Drikold, and Distillers Co Ltd who use the name Cardice.

A fairly recent development by ICI is the VanCooler which is intended to meet the need fbr a low-cost system for delivery vans operating in the range 35 to 50deg F. The VanCooler operates thermostatically and costs only £60. It consists of an insulated container which will hold about 1201b of crushed Drikold and a fan operates to give a higher cooler rate—a switch cuts off the fan when the doors open. The VanCooler takes 2.7 sq.ft. of floor space, weighs 621b and a full charge gives a total cooling capacity of 32,000 btu. Optimum cooling rate is up to 6,000 btuthr while the maximum rate for short periods can be 20,800 btuihr.

Liquid gas BOTH liquid nitrogen and liquid carbon dioxide are marketed for vehicle refrigeration applications. At one time there was a possibility that liquid air would also be introduced but this has not materialized and although Philips reports a limited success in Europe there is a need for large scale production of liquid air to make this commodity economic. Pye Unicam Ltd, of Cambridge handles the Philips system in the UK.

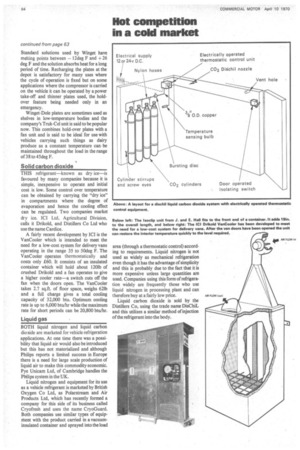

Liquid nitrogen and equipment for its use as a vehicle refrigerant is marketed by British Oxygen Co Ltd, as Polarstream and Air Products Ltd, which has recently formed a company for this side of its business called Cryofresh and uses the name CryoGuard. Both companies use similar types of equipment with the product carried in a vacuuminsulated container and sprayed into the load