WHY THE STEAMER IS CHEAPER.

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

Detail Improvement in Engine Construction and Particularly in Valve Design Responsible for Improved Economy of Steam Wagons.

'THE vastly improved economy of the steam wagon 1_ which has been made so evident of late is owing to Many things. Some I have already indicated in previous articles; another, upon which I should here like to dilate, is the improvement in the design and construction of-the engine valve gear and, more par.ticularly, of the steam-distributing valve itself. This improvement is to be noted in two directions: there is the improvement in the design of the valve, whereby It N made much easier to operate (so that it con

sumes—wastes, we should say—less of the engine • power) and there is the modification in its working, whereby the distribution of the steam is bettered and loss by wire-drawing and other causes is eliminated. I will deal, first of all, with the way :n which the design of the valve itself has been improved.

Disadvantages of an Unbalanced Slide Valve.

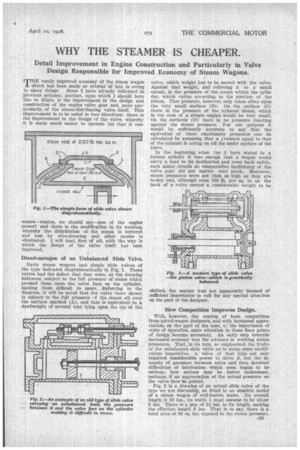

Early steam wagons had simple slide valves of the type indicated diagrammatically in Fig. 1. These valves had the defect that they were, as the drawing indicates, subject to the full pressure of steam which pressed them upon the valve face on the cylinder, making them difficult to move. Referring to the diagram, it will be noted that the valve there shown is subject to the full pressure 4 the steam all over the surface marked (A)., and that is equivalent to a deadweight of several tons lying upon the top of the

valve, which weight has to be moved with the valve. Against that weight, and relieving it to a small extent, is the pressure of the steam within the cylinder, which varies according to the position of the piston. That pressure, however, only takes effect upon the very small surface (B). On the surface (C) there is the pressure of the exhaust steam, which in the case of a simple engine would be very small. On the surfaces (D) there is no pressure reacting against the steam pressure. For our purpose it would be sufficiently accurate to say that the equivalent of these reactionary pressures can be calculated by assuming that a iressure equal to that of the exhaust is acting on all the under surface of the valve.

In the beginning, when (as I have stated in a fermer article) it was enough that a wagon would carry a load to its destination and come back safely, such minor details as comparative inefficiency of the valve gear did not matter very, much. Moreover, steam pressures were not then so high as they are to-day and, although even 100 lb. per sq. in. on the back of a valve means a considerable weight to be

shifted, the matter was not apparently, deemed of sufficient importance to call for any special atter_tion on the part of the designer.

How Competition Improves Design.

With, however, the coming of keen competition from petrol-wagon designers, and with increased appreciation, on the part of the user, 02 the importance of costs of operation, more attention to these finer points of design becaine necessary. An early step towards increased econoray was the advance in working steam pressures. That, in its turn, so emphasized the feults of the unbalanced slide valve as to make some modification imperative. A valve of that type not only required considerable power to drive it, but the intensity of pressure between valve and face involved difficulties of lubrication which soon began to be serious; how serious may be better understood, perhaps, if an appreciation of the actual pressure on the valve face be gained.

Fig. 2 is a drawing of an actual slide valve of the type we are discussing, as fitted to an obsolete model of a steam wagon of well-known make. Its overall length is 93 ins., its width I must assume to be about 6 ins. There is a gap of 31 ins in its length, making the effective length 6 ins. That is to say, there is a total area-of 36 sq. ins, exposed to the steam pressure, which, if that were 230 lb., would mean that the valve would be carrying a total load of 8,280 lb., nearly 34 tons! If we allow for a pressure of 5 lb. per sq. in. on the underside, that only reduces the total by the negligible amount of 180 lb. It must ,take quite an appreciable amount of power to move this valve, all of which effortis lost.

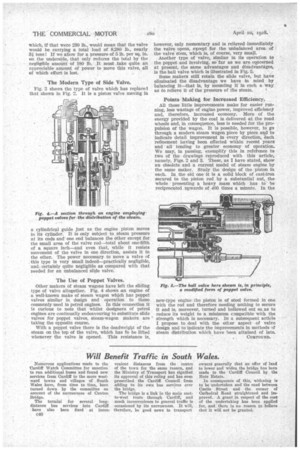

The Modern Type of Side Valve.

Fig. 3 shows the type of valve which has replaced that shown in Fig. 2. It is a piston valve moving In

a cylindrical guide just as the engine piston moves in its cylinder. It is only subject to steam pressure at its ends and one end balances the other except for the small area of the valve rod—total about one-fifth of a square inch—and even that, while it resists movement of the valve in one direction, assists it in the other. The power necessary to move a valve of this type is very small indeed—practically negligible, and. certainly quite negligible as compared with that needed for an unbalanced slide valve.

The Use of Poppet Valves.

Other makers of steam wagons have left the sliding type of valve altogether. Fig. 4 shows an engine of a well-known make of steam wagon which has poppet valves similar in design and operation to those commonly used in petrol engines. In this connection it is curious to note that whilst designers of petrol engines are continually endeavouring to substitute slide valves for poppet valves, steam-wagon makers are taking the opposite course.

With a poppet valve there is the deadweight of the steam on the top of the valve, which has to be lifted whenever the valve is opened. This resistance is, however, only momentary and is relieved immediately the valve opens, except for the unbalanced area• of the valve stem, which is, of course, very small.

Another type of valve, similar in its operation to the poppet and involving, so'far as we are cqncerned at present, the same advantages and disadvantages, is the ball valve which is illustrated in Fig. 5.

Some makers still retain the slide valve, but have eliminated the disadvantage we have in mind by balancing it—that is, by mounting it in such a 'way as to relieve it of the pressure of the steam.

Points Making for Increased Efficiency.

All these little improvements make for easier running, less wastage of engine power, improved efficiency and, therefore, increased economy. More of the energy provided by the coal is delivered at the road wheels and, in consequence, less is needed for the propulsion of the wagon. It is possible, however, to go through a modern steam wagon piece by piece and to indicate detail improvement in every direction, each refinement having been effected within recent years and all tending to greater economy of operation. We may, in passing, exemplify this in refekence to two of the drawings reproduced with this article, namely, Figs. 2 and 3. These, as I have stated, show an obsolete and a current model of steam engine by the same maker. Study the design of the piston in each. In the old one it is a solid block of cast-iron secured to the piston rod by a substantial nut, the whole presenting a heavy mass which has to be reciprocated upwards of 400 times a minute. In the

new-type engine the piston is of steel formed in one with the rod and therefore needing nothing to secure It and is, moreover, turned and hollowed out so.. as to reduce its weight to a minimum compatible with the strength which is necessary. In a subsequent article I propose to deal with the other aspect of valve -design and to-indicate the improvements in methods of steam distribution which have been attained of late.

COMPOUND.