BRITISH TROLLEYBUSES

Page 94

Page 95

Page 96

Page 97

If you've noticed an error in this article please click here to report it so we can fix it.

for modern

;ystems

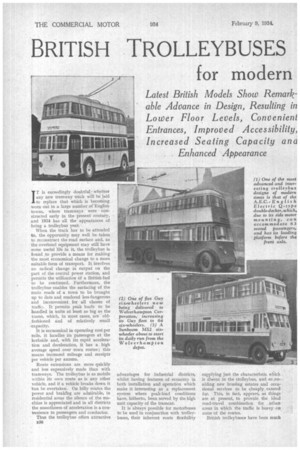

Latest British Models Show Remarkable Advance in Design, Resulting in Lower Floor Levels, Convenient Entrances, Improved Accessibility, Increased Seating Capacity and Enhanced Appearance IT is exceedingly doubtful whether any new tramway track will be laid to replace that which is becoming worn out in a large number of English towns, where tramways were constructed early in the present century, and 1934 has all the appearances of being a trolleybus year.

When the track has to be attended to, the opporunity may well be taken to reconstruct the road surface and, as the overhead equipment may still have some useful life in it; the trolleybus is found .to provide a means for making the most economical change to a more suitable form of transport. It involves no radical change in output on the part of the central power station, and permits the utilization Of a British fuel to be continued. Furthermore, the trolleybus enables the surfacing of the main roads of a town to be brought up to date and rendered less dangerous and inconvenient for all classes of traffic. It permits peak loads to be handled in units at least as big as the trams, which, in most cases, are oldfashioned and of relatively small

• capacity.

It is economical in operating cost per mile, it handles its passengers at the kerbside and, with its rapid acceleration and deceleration, it has a high average speed over town routes; this means increased mileage and receipts per vehicle per annum.

Route extensions are more quickly and less expensively made than with tramways. The trolleybus is as mobile within its own route as is any other vehicle, and if a vehicle breaks down it tan be overtaken. On hilly routes the power and braking are adniirable, in residential areas the silence of the machine is appreciated and in all districts the smoothness of acceleration is a convenience to passengers and conductor.

Thus the trolleybus offers attractive advantages for industrial districts, whilst having features of economy in both installation and operation which make it interesting as a replacement system where peak-load conditions have, hitherto, been served by the high unit capacity of the tramcar.

It is always possible for motorbuses to be used in conjunction with trolleybuses, their inherent route flexibility

supplying just the characteristic which is dbeent in the trolleybus, and so .en-. abling new housing estates and occasional services to be cheaply. catered for. This, in fact, appears i as things are at present, to provide the ideal road-travel combination for urban areas in which the traffic is heavy on some of the routes.

British trolley-buscs have been much

improved in the past year or two, particularly as to the disposition of the motor and in the arrangement of the loading platform and seating layout. In the following pages we review the latest types, drawing attention to some of their outstanding features:—

A.E.0

THE new A.E.C.-English Electric Q.1. type trolleybus, like the A.E.C. Q-type motorbus, has its power unit mounted outside the frame on the off side of the chassis, and is one of the most advanced forms of trolleybus that the world has yet seen. The chassis is, of course, the product of the Asoelated Equipment Co., Ltd., Southall, Middlesex.

The position of the motor makes it possible to provide for the entrancs: platform before the front axle, and adjacent to the driver, whb, as a resuit, can himself saperVise the unloading and loading of passengers, without having to rely upon a signalling system with the conductor, which never has proved altogether satisfactory.

This new feature results in increased speed and greater safety—the former because the driver can pull up immediately opposite intending passengers and can move off the moment they are aboard, the latter because he need never be in doubt whether all are safely on the vehicle before he moves off.

As an accompanying illustration shows, the design permits of wellstreamlined and attractive bodywork, allows for a waximup of seating space in proportion to the street area covered by the vehicle, and affords a lugn degiee of accessibility for the motor and other principatchassis components. The designer has almost a free band so far as the shape of the near-side frame longitudinal is concerned, and a low floor height is obtained.

GLOSTER.

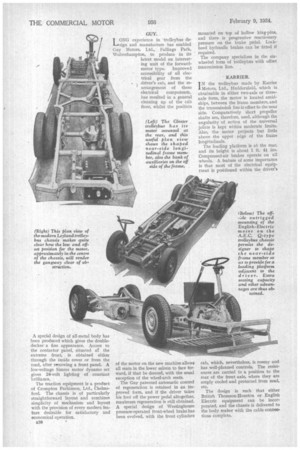

AA NEWCOMER to the 'market, yet of particular interest because of its low floor height and convenient central entrance, is the Gloster trolleybus made by the Gloucester Railway Carriage and Wagon Co., Ltd., Gloucester. Having been designed only last year, it embodies no old ideas whatever.

The motor is located behind the rear axle and offset from the longitudinal axis of the vehicle so that the .differential _case does not obstruct the gangway floor. The auxiliaries are conveniently located in a bank outside the main frame on the off side (between the axles), where they are completely insulated on Floatex mountings and are easily accessible. A special design of all-metal body has been produced which gives the doubledecker a fine appearance. Access to the contactor panel, situated al the extreme front, is obtained either through the inside cover or from the road, after removing a front panel. A low-voltage Simms motor dynamo set gives 24-volt lighting of constant brilliance.

The traction equipment is a product of Crompton Parkinson, Ltd., Chelmsford. The chassis is of particularly straightforward layout and combines simplicity of mechanism and layout with the provision of every modern feature desirable for satisfactory and economical operation.

ESS GUY.

LONG experience in trolleybus de1--tsign and manufacture has enabled Guy Motors, Ltd., Fallings Park, Wolverhampton, to produce in its latest model an interesting unit of the forwardmotor type. Improved accessibility of all electrical gear from the driver's cab, and the rearrangement of these

electrical components, has resulted in a general cleaning up of the cab floor, whilst the position of the motor on the new machine allows all seats in the lower saloon to face forward, if that be desired, with the usual exception of the wheel-arch scats.

The Guy patented automatic control of regeneration is retained in an improved form, and if the driver takes his foot off the power pedal altogether, maximum regeneration is still obtained. A special design of Westinghouse pressure-operated front-wheel brake has been evolved, with the front cylinders mounted on top of hollow king-pins, and there is progressive reactionary pressure on the brake pedal. Lockheed hydraulic brakes can be fitted if required. The company specializes in the sixwheeled form of trolleyhus with offset transmission line.

KARRIER.

IN the trolleybus made by Karrier Motors, Ltd., Huddersfield, which is obtainable in either two-axle or threeaxle form, the motor is located amidships, between the frame members, and the transmission line is offset to the near side. Comparatively short propeller shafts are, therefore, used, although the angularity of action of the universal joints is kept within moderate limits. Also, the motor projects but little above the upper edge of the frame longitudinals.

The loading platform is at the rear, and its height is about 1 ft. 4i ins. Compressed-air brakes operate on all wheels. A feature of some importance is that most of the electrical equipraent is positioned within the driver's cab, which, nevertheless, is roomy and has well-planned controls. The resistances are carried in a position to the rear, of the front axle, where they are amply cooled and protected from mud. etc.

The design is such that either British Thomson-Houston or English Electric equipment can be incorporated, and the chassis is delivered to the body maker with the cable connections complete. LEYLAND.

THE Leyland-G.E.C. trolleybus, produced by Leyland Motors, Ltd., Leyland, Lancs. and having equipment by the General Electric Co., Ltd., is a new model and differs from its prototype in that, instead of the motor being mounted fairly high up in the front end of the chassis, it is now positioned between the frame members amidships.

In the six-wheeler the motor is well offset to the near side, the transmission line being similarly offset. Thus, the motor is clear of the gangway, whilst the propeller shaft is as short as it can be without introducing excessive working angles for the universal joints. The resistances are carried below the frame, in front of and behind the front axle, where they are well protected from rain, mud, stones, etc.

The bogie of the six-wheeler has been . completely redesigned to include two semi-elliptic springs on each side, and to do away with the torque-reaction blade previously employed. Torque is thus transferred to the frame instead of being absorbed in the bogie, and even with severe braking there is no tendency whatever for the bogie to tip forward.

A feature of the new model is the use of 8-in, centres for the worm and worm wheel of the final drive. The standard range is designed for bodies seating from 30 to 66 passengers.

The motors fitted as standard in the Leyland trolleybuses are the 65 b.h.p. type in the two-axled single-decker and the 80 b.h.p. type in the other models. The fact that the motors are interchangeable, however, means that service condition can be met which call for comparatively high or low power.

Compressed-air braking is standardized throughout the Leyland range, although electric-assisted, vacuumassisted, electric-regenerative • or rheostatic systems are offered as optional equipment. The compressed-air cylinders act directly on the ends of the camshaft levers, ensuring complete compensation without the need for complicated multiplying levers, and without any call for frequent adjustment. One set of wide shoes is fitted to each rear-wheel drum, as well as to each front-wheel drum.

RANSOMES.

T HE latest trolleybus produced by

Ransomes, Sims and jefferies, Ltd., Ipswich, is of the two-axle, singlemotored type, the motor being planed in the middle of the chassis, centrally between the frame members. A sixwheeler with the motor similarly placed also is available. The loading platform is, in each case, arranged at the rear.

On the latest vehicles are employed the saturated field system of control and the regenerative system. The latter, incorporating Ransornes' patents, is so combined with the air-operated foot brake that regenerative braking automatically takes place whenever the mechanical brakes are applied. By this means maximum regeneration is obtained, thus reducing current consump

tion and increasing the life of the wearing parts of the mechanical brakes.

Whichever system of control be employed, the contactor type of controller always is adopted. The total number of speeds provided is 12, of which eight represent economic speeds that can be used without waste of energy in resistances.

The motor is of Ransornes design and make, and features the use of light alloys and a special attention to ventilation. The resistances are carried in the front of the vehicle above the axle and beneath the floor of the driver's cab, where adequate ventilation is obtained without exposure to rain, mud or dust.

In the six-wheeler a third differential is incorporated to equalize the drive between the rear axles, irrespective of the pressure and consequent effective diameter of the tyres.

SUNBEAM.

AA RANGE of four-wheelers and sixwheelers is at present offered by the Sunbeam Motor Car Co., Ltd., Wolverhampton, the four-wheelers including the MF1 and MF2 types for

single and double-decker bodies respectively, both of which have the motor mounted centrally, and the MF2A double-decker model, which is similar except that the motor is mounted immediately behind the front axle, under the driver's .cab ; the object of this is to provide for a low overall height, rendering the vehicle suitable for roads where low bridges have to be passed.

The six-wheelers comprise. the MS2, which has the motor mounted centrally amidships, and the MS3, which has the motor amidships but offset, so as to bring it beneath the seats and to provide a floor free from obstruction.

The MS2 six-wheeler, with the central motor, is intended particularly for double-deckers of large seating capecity, accommodating up to 64 passengers and having ample standing room for dealing with heavy peak-load traffic.

The design of the frame for the MS3 six-wheeler is of interest because of the cruciform members which are employed to give extreme rigidity and strength to the frame, and to provide a suitable mounting for the offset motor. The silent contactors are a feature of the British Thomson-Houston electrical equipment.