EFFICIENCY in MC )ERN ENGINE DESIGN

Page 106

Page 107

Page 108

If you've noticed an error in this article please click here to report it so we can fix it.

More Efficient and Reliable Powerunits Now Available, Although No Startling Changes in Design are Apparent

/T is always difficult when reviewing progress to avoid unduly stressing the latest developments, so that in a discourse on engine design, one is apt to turn immediately to the oil engine for inspiration. Yet, whilst there can he no doubt about the rapid strides made by the relatively high-speed compression-ignition unit suitable for road vehicles, its advancement to its present state of efficiency is not by any means the whole story.

Petrol engines still form the majority of the power units in use on passenger vehicles. Although the oil engine is steadily forcing its way, for economic and other reasons, into the fields of activity covered by 'buses and coaches, opinions as to the desirability of one type or the other are obviously divided. This statement is proved by the fact that practically all chassis manufacturers list alternative units.

Similarity of Oil and Petrol Power Units.

Although the principles upon which these two types of power-unit operate differ greatly, their general constructional features are similar. The oil engine is. neceesarily more robust, due to the higher maximum pressures during compression and burning, and whilst this factor alone calls for special treatment in the shape of larger bearing surfaces, more substantial bolts for the crankshaft-bearing caps, etc., the design of the components concerned is similar to that of the equivalent parts of the petrol engine.

One might even go so far as to suggest that, following the developE48 ment of the oil unit from the petrol engine, there has since been a development in the latter type, subsequent to the standardization of design of the heavier engine.

By this is meant that the gospel of rigidity preached by everybody connected with automobile-engine design has been relearnt with advantage to all concerned. Such components' as cylinder blocks, crankcases and crankshafts are tending to become stiffer, but the changes are being effected subtly.

This indicates that the petrol engine has gone a long way towards the ultimate goal of perfection, and it is only When one analyses the thermalefficiency figures attained by even modern engines that one realizes how

far off perfection really is Again, that is another story, as it concerns future possibilities of a radical nature.

Other points being equal, a stiffer crankshaft usually means less torsional vibration, and in long engines this is a most important factor in the search for smooth running, because the vibration is usually of apparent low frequency and causes, in bad cases, a heavy rumble. Torsional strength is not entirely dependent upon weight— t, small increase in diameter makes a

lot of difference. The cores of the main hearings and the crankpins are of little value so far as strength is concerned, so that a large-diameter hollow crankshaft is indicated.

This brings forward another point. The overall length of some power-units is governed not so much by the bore of the cylinders, as by the size of the crankshaft journals and webs. It follows, therefore, that by increasing the diameter, the length of the journals can be reduced, at the same time maintaining sufficiently large bearing surfaces to prevent undue wear from occurring, Against this, of course, must be placed the fact that rubbing speeds are slightly increased, but not to the point where they become dangerously high.

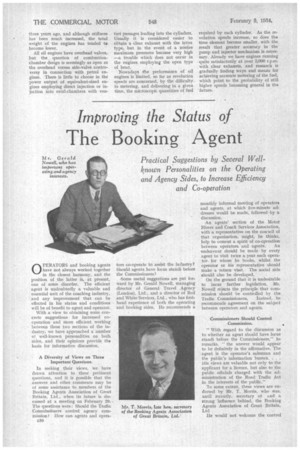

The advent, some years ago, of aluminium pistons coincided with an epidemic of rapid wear in cylinder bores and excessive oil consumption. Gradually this trouble has been overcome, fortunately, without having to resort to palliatives; improvement has been effected by employing better materials and by carefpl design of the parts concerned.

For example, centrifugally cast cylinder_liners giving a larger Brinell figure than ordinary iron have helped matters considerably, whilst composite pistons having aluminium-alloy heads (to give high.thermal conductivity) and steel or cast-iron skirts providing long-wearing qualities, have made a practical solution of the problem. Furtherniore, research with regard to piston-ring design has also led to all-round improvements in pres sure seal and in the reduction of oil consumption through the lubricant passing up through the rings in the combustion heads.

Whilst dealing with this matter, mention should be made of the general increase in efficiency of filtering arrangements. No lubricant, however good it may be, can work satisfactorily with even a modicum of abrasive suspended in the fluid. Dust and road grit are severe abrasives, and their exclusion from the internal parts of an engine is essential if long life be a consideration.

Air filters to the carburetters and special filtering arrangements for the oiling system have become almost standard fittings on both petrol and oil engines. 'In several designs, the temperature of the oil is Controlled by a cooler, in order to maintain the viscosity factor at a reasonably high figure.

One could deal with every component, small changes having been made here and there which, in themselves, are rather insignificant, but which, in the aggregate, become of vital importance.. It is no exaggeration to say that nowadays engines are far more reliable, whilst they will continue running satisfactorily for far longer periods than was possible a few years ago.

Controversy as to the relative merits of overhead or side-by-side valves has existed since the automobile industry came into being. Adherents to the overhead type claim that no other arrangement of valves is so highly efficient, whilst protagonists of the side-by-side type say that this argu..ment is fallacious. .

There is no indication, at the moment, of a general change-over from one type to the other, so we are left to assume that the simplicity of the side-valve design counterbalances any • greater efficiency of the overhead layout.

Some Features of Valve Developments.

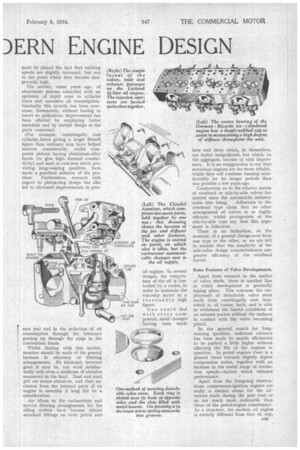

Apart from research in the matter of valve steels, there is another line in which development is gradually taking place. This concerns the employment of detachable valve seats made from centrifugally cast iron, which is, of course, hard, and is able to withstand the heated conditions of an exhaust pocket without the surfaces in contact with the valve becoming pitted.

In the general search for longwearing qualities, sufficient advance has been made to enable efficiencies to be pushed a little higher without affecting the life of the engines in question. In petrol engines there is a general trend towards slightly higher compression ratios, together with an increase in the useful range of revolution speeds—factors which enhance performance. Apart from the foregoing observations, compression-ignition engines are really a subject alone, for the ad. vances made during the past year or so are much more noticeable than those of the petrol-engine counterpart. As a structure, the modern oil engine is entirely different from that of, say, three years ago, and although stiffness has been much increased, the total weight of the engines has tended te become lower.

All oil engines have overhead valves,but the question of combustionchamber design is seemingly as open as the overhead versus side-valve controversy in connection with petrol engines. There is little to choose in the power output of equivalent-sized engines employing direct injection or injection into swirl-chambers with ven turi passages leading into the cylinders. Usually it is considered easier to obtain a clear exhaust with the latter type. but in the event of a misfire maximum pressures become very high —a trouble which does not occur in the engines employing the open type of head.

Nowadays the performance of oil engines is limited, so far as revolution speeds are concerned, by the difficulty in metering, and delivering in a given time, the microscopic quantities of fuel required by each cylinder. As the revolution speeds increase, so does the time element become smaller, with the result that greater accuracy in the pump and injector mechanism is. necessary. Already we have engines running quite satisfactorily at over 3,000 r.p.m. with clear exhausts, and research is gradually finding ways and means for achieving accurate metering of the fuel, which point to the probability of still higher speeds becoming general in the future.