A NEW RANGE OF COMMER CHASSIS.

Page 98

Page 99

Page 100

If you've noticed an error in this article please click here to report it so we can fix it.

Forward and Normal-type Sixwheelers and Four-wheelers. A Simple 30-cwt. Chassis and a 2-ton Small-wheeled Low-loader.

FROM the very early days of cone mcrciaI motoring the name Coturner has been associated with vehicles remarkable for their reliability and long life, whilst they embodied certain unusual features which served to distinguish them from the general run. With such a reputation it behoves the maker to tread very warily in producing new models, but from what we have seen of the six chassis forming the entirely new range made by Commer Cars, Ltd:, of Luton, and the performance of certain of them on the road, we believe that the good reputation already achieved will not only be maintained but enhanced.

In producing these vehicles the designer has had six main objects in view, and we give them in the order in which they were quoted. First came ease in driving, and every endeavour has been made to afford the driver as much comfort as his confrere of the touring car ; secondly, adequate braking power, this being assisted by the provision of relatively large drums and wide shoes on front and rear wheels, these brakes being controlled through a Dewandre servo ; third on the list came easy steering, and, the gear employed to ensure this is the Merles; next was good suspension; fifth, interchangeability of frames and main units as between sixwheelers and four-wheelers; and, lastly, the prevention of frame racking by adequate bracing.

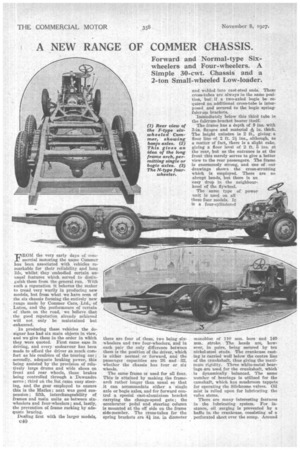

Dealing first with the larger models, 040

there are four of these, two being six-wheelers and two four-wheelers, and in each pair the only difference between them is the position of the driver, which is either normal or forward, and the passenger capacities are 26 and 32, whether the chassis has four or six wheels.

The same frame is used for all four. This is attained by making the framearch rather longer than usual so that it can accommodate either a single axle or bogie axles, and for forward control a special cast-aluminium bracket carrying the change-speed gate ; the accelerator pedal and steering column is mounted at the off side on the frame side-member. The cross-tubes for the spring brackets are 4i ins. in diameter

and N-veltled into cast-steel ends. These eross-tubes are always in the same position, but if a two-axled bogie be required an additional cross-tube is interposed and secured to the bogie springfulernm brackets.

Im:niediately below this third tube is the fulcrum-bracket bearer itself.

The frame has a depth of 9 ins, with

flanges and material et in. thick. The height unladen is 2 ft., giviug, a floor line of2 ft. 21 ins., although, as a matter of fact, there is a slight rake, giving a floor level of 2 ft. 5 ins, at the rear, but as the entrance is at the front this merely serves to give a better view to the rear passengers. The frame is enormously strong, and one of our drawings shows the cross-strutting which is employed. There are no abrupt bends, but there is an easy drop in the neighbourhood of the flywheel.

The same type of power unit is used on all these faur models. It is a four-eylindered monohloc of 110 rem. bore and 140 mm. stroke. The heads are, however, in pairs, being secured by ten nickel-steel !studs. The crankcase casting is carried well below the centre line of the crankshaft, thus giving the maximum rigidity. Three white-metal bearings are used for the crankshaft, which' is dynamically balanced. The same number of bearings is utilized for the camshaft, which has mushroom tappets for operating the Slichrome valves. Oil mist is relied upon for lubricating the valve stems.

There are many interesting features in the lubricating system. For instance, oil surging is prevented by a baffle in the crankcase, consisting of a perforated sheet over the sump. Around

tho gear-type oil pump, which is driven by spiral gears from the 'Camshaft, is

a large suction filter. There are no loose lubricating pipes, with the exception of•that to the pressure gauge. The main distribution pipe is cast. into the crankcase ; from this the oil passes to the main bearings through ducts drilled in the crankcase, whilst the big-ends are supplied through the crankshaft. rurther ducts from the main oil pipe convey oil to the camshaft, magneto and dynamo-drive bearings. Serewe•d plugs are provided at the end of each duct, so that these can be cleaned with out taking down the engine.

A feature of the oil pump IS that it is easily removable for inspection or repair ; access to it is obtained by removing the external filter easing situated at the near side of the engine and unscrewing one nut only.

The dynamo and, magneto drives are mounted in eccentric bushings, which can be adjusted to secure the eqrreet meShing of the timing gears, these being of the straight-toothed type, with a Fibrax intermediate pinion.

The water primp is driven by an extension of the fan spindle, and there is a shroud around the propeller to direct water to the valve Beatings. A sliding flange of the V-pulley provides

simple means for adjusting the belt. An oil filler is accessibly situated at the near side of the timing case, whilst a dip-stick is provided behind the external filter. A square-type inlet manifold is employed, and the system embodies a hot-spot consisting of a casting bolted between the cast-aluminium

inlet conneotion and the exhaust manifold. Under a large brass cap on the timing case is the adjustable relief valve for the oil.

, To facilitate inspection of the bigends, etc., there are, two large doors at the off side of the crankcase.

Lightness of the reciprocating parts is assisted by the employment of iSpecialloid pistons.

At the base of the dip-stick is a nut, and on this being released the oil in the sump can be run into a suitable receptacle such as a bucket.

The power developed by the engine is 42 b.p.h. at 1,000 r.p.m., 60 b.h.p. at 1,500 r.p.m. and 13 b.h.p. at 2,000 r.p.m., the maximum b.h.p. obtained 5iag 84. It is interesting to mention that a Most remarkable test was recently carried out with an engine of this type. After being in a vehicle and runfling on the road for a• week, the unit was taken out and given a nonstop test of 110 hrs. ; of these, 5 hrs. were at onethird power, 5 hrs.

at three-quarter power and 90 has at full power, and this without the slightest sign of failure. •

A new and handsome radiator radiator of the header-and-bottomtank type is employed. It is carried on rubber buffers on the front cross-member of the frame, and is thus free from racking; the nuts by which it is secured are spherically seatect An open flywheel with an invertedcone clutch faced with Raybestos is

utilized. This clutch can be removed without disturbing the gearbox. Lubrication of the -clutch spigot is effected automatically by a small spring-held Poppet valve with a hard felt washer to damp down the pressure, a small amount of oil being passed to the spigot bush every time the clutch pedal is dePressed. The clutch stop Consists of a large steel disc, which is pressed forward against a plate faced with Raybestos and mounted on the cross-member carrying the operating gear. Two Hermetic joints are used on the clutch shaft.

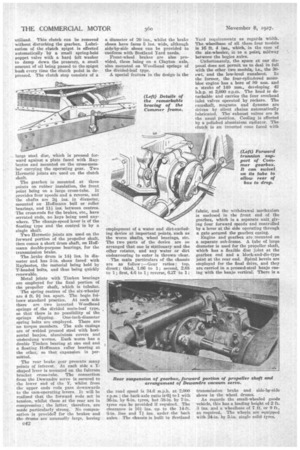

The gearbox is mounted at three points on rubber insulation, the front point being on a large cross-tube. It provides four speeds and a reverse, and the shafts are 24 ins. in diameter, mounted on Hoffmann ball or roller bearings, and 114 ins, between centres. The cross-rods for the brakes, etc., have serrated ends, no keys being used anywhere. The change-speed lever is of the floating type and the control is by a single shaft.

Two Hermetic joints are used on the forward portion of the propeller shaft, then comes a short drum shaft, on Hoffmann double-purpose bearings, for the transmission brake.

The brake drum is 141 ins, in diameter and has 3-in, shoes faced with Raybestos, the material being held by T-headed bolts, and thus being quickly renewable.

Metal joints with Timken bearings are employed for the final portion of the propeller shaft, which is tubular.

The spring centres of the six-wheeler are 4 ft. 91 ins. apart. The bogie follows standard practice. At each side there are two inverted Woodhead springs of the divided main-leaf type, so that there is no possibility of the springs slipping. One-inch-diameter spring bolts are employed. There are no torque members. The axle casings are of welded pressed steel with horizontal banjos, aluminium covers and underslung worms. Each worm has a double Timken bearing at one end and a floating Hoffmann roller bearing at the other, so that expansion is permitted.

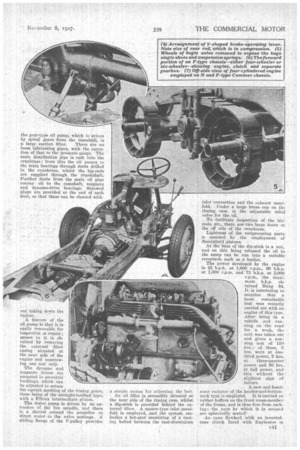

The rear brake gear presents many points of interest. At each side a shaped lever lever is mounted on the fulcrum bracket cross-tube. The connection from the Dewandre servo is secured to the lower end of the Y, whilst from the upper ends rods pass downwards to the cam-operating levers. It will be realized that the forward rods act in tension, whilst those at the rear are in compression ; the latter, therefore. are made particularly strong. No compensation is provided' for the brakes and the drums are unusually large, having C42 a diameter of 20 ins., whilst the brake shoes have faces 5 ins, wide, although side:by-side shoes can be provided to conform with Scotland Yard needs.

Front-wheel brakes are also provided, these being on a Clayton axle, also mounted on Woodhead springs of the divided-leaf type.

A special feature in the design is the employment of a water and dirt-excluding device at important points, such as the worm shafts, wheel bearings, etc. The two parts of the device are so arranged that one is stationary and the other rotates, and any water or dirt endeavortring to enter is thrown clear.

The main particulars of the chassis are as follow :—Gear ratios: top, direct ; third, 1.66 to 1; second, 2.88 to 1 ; first, 4.6 to 1; reverse, 6.27 to 1; the road speed is 34.6 m.p.h. at 2,000 r.p.m. ; the back-axle ratio is 61 to 1 with 36-in. by 6-in. tyres, but 38-in. by tyres can be provided if required.. The clearance is 10i ins, up to the 14-ft. 6-in, line and 7+ ins, under the back axles. The chassis is built te Scotland Yard requirements as regards width. The wheelbase of all these four models is 16 ft. 4 ins., which, in the ease of the six-wheeler, is to a point, midway between the bogies axles.

Unfortunately, the space at our disposal does not permit us to deal in full with the other two models, i.e.' the 30cwt. and the low-level runabout.

the former, the four-cylindered monobloc engine has a bore of 80 nun, and a stroke of 140 mm., developing 42 b.h.p. at 2,000 r.p.m. The head is detachable and carries the four overhead inlet valves operated by rockers. The camshaft, magneto and dynamo are driven by silent chains automatically lubricated. The exhaust valves are in the usual position. Cooling is effected by a polished aluminium radiator. The clutch is an inverted cone faced with fabric, and the withdrawal mechanism is enclosed in the front end of the gearbox, which is a separate unit giving four forward speeds and controlled by a lever at thil side operating through a gate secured the gearbox casing.

Engine and gearbox are mounted on a separate sub-frame. A tube of large diameter is used for the propeller shaft, which has a flexible disc joint at the gearbox end and a block-and-die-type joint at the rear end. Spiral bevels are employed for the final drive, and they are carried in a pressed-steel banjo easing with the banjo vertical. There is a transmission brake and side-be-side shoes in the wheel drums.

As regards the small-wheeled goods vehicle, this has a loading height of 2 ft. 3 ins, and a wheelbase of 7 ft. Or 9 ft., as required, The wheels are equipped with 24-in. by 57in, single solid tyres.