THE LATEST PRODUCTS OF THE HALLEY WORKS.

Page 117

Page 118

If you've noticed an error in this article please click here to report it so we can fix it.

Details of the New Rigid Six-wheeler for Passenger Service, and a Two-ton Model Developed from the Subsidy Pattern.

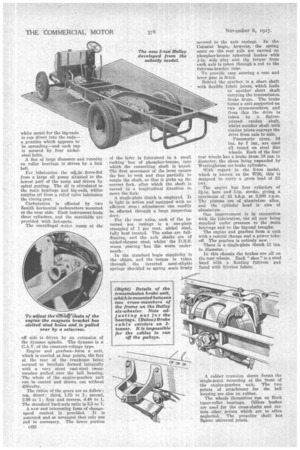

ABOUT a year ago we were able to publish the first illuatration of the Halley rigid-frame six-wheeled chassis. Unfortunately at that time the company was not able to continue with its construction, but now Halley Motors, Ltd., has actually built some new six-wheelers embodying improvements -upon the original pattern. In addition, the company has built another four-wheeled model to carry 2 tons and to come within the a6 tax category. This latter machine is a development of the subsidy model with an extended wheelbase, pointed radiator, roller bearings for the wheels and a divided propeller shaft, but for the moment we will proceed with a brief description of the six-wheeled ,chassis, this being constructed in two types, one for 30-passenger bodies with the driver acCommodated beside the engine, and the other a normal-contro chassis for bodies seating 30 passengers. Except RS regards the forward control in one model the chassis are Similar.

The engine has six cylinders of 95 mm. bore and 110 mm. stroke, cast en bloc and with a detachable head in one piece.. It is rated at 316 li.p., but develops 40 b.h.p. at 1,000 r.p.m. and 72 b.p.h. at 2,000 r.p.m.The crankshaft

is Carried in four bearings, carried in the upper half of the crankcase, and the camshaft is driven by a silent chain. Stainless steel is used for the exhaust valves aial 3 per cent, nickel steel for the inlet, whilst the pistons are of castiron having large-diameter hollow gudgeon pins, it is notable that the white metal for the big-ends is run direct into the rods— a practice which appears to be spreading—and each cap is secured by four nickelsteel bolts.

A fan of large diameter and running on roller bearings in driven by a link belt.

For lubrication the oi4is force-fed from a large oil pump situated in the lowest part of the sump and driven by spiral gearing. The oil is circulated to the main bearings and big-ends, whilst surplus oil from a relief valve lubricates the timing gear.

Carburation is effected by two Zenith horizontal carburetters mounted at the near side. Each instrument feeds three cylinders, and the manifolds are provided. with hot-spots.

The centrifugal water nutnp at the off side is • driven by an extension of the dynamo spindle. The dynamo is a C.A.V. of the constant-voltage type.

Engine and gearbox– form a unit, which is carried at four points, the feet at the rear of the crankcase being secured to brackets formed integrally with a very stout cast-steel CPOSSmember arched over the bell housing. The whole of the engine-gearbox unit can he canted and drawn out without difficulty.

The ratios of the gears are as follow : top, direct ; third, 1.75 to 1; second, 2.98 to 1; first and reverse, 4.48 to 1. The standard back-axle ratio is 5.5 to 1.

A new and interesting form of changespeed control is provided. It is patented and so arranged that only one rod is necessary. The lower portion C60

of the lever is fulertimed in a small rocking box of phosphor-bronze, into which the connecting shaft is keyed. The first movement of the lever causes the box to rock and thus partially to rotate the shaft, so that it picks up the correct fork, after which the shaft is moved in a longitudinal direction to move the fork.

A single-plate clutch is employed. It is light in action and equipped with an efficient stop ; adjustment can readily be effected through a large inspection door.

For the rear axles, each of the inverted pot casings is a one-piece stamping of 1 per cent, nickel steel, fully heat treated. The axles are fullfloating, and the axle shafts are of nickel-chrome steel, whilst the D.B.S.

worm gearing ' has worm underneath.

In the standard bogie simplicity Is the object, and the torque is taken threngh the inverted semi-elliptic springs shackled to spring seats firmly secured to the axle casings. In the Colonial bogie, however, the spring seats on the rear axle are carried on phosphor-bronze spherical bashes with /-in. side play and the torque from each axle is taken through a rod to the fulcrum-bracket tube.

To provide easy steering a cam and lever gear is fitted.

Behind the gearbox is a short shaft with flexible fabric joints, which leads to another short shaft carrying the transmission brake drum. The brake forms a unit supported on two cross-members, and from this the drive is taken by a Spicerjointed cardan shaft, whilst another shaft with similar joints conveys the drive from axle to axle.

Pneumatic tyres, 34 ins. by 7 ins., are used all round on steel disc wheels. Each of the four rear wheels has a brake drum 18 ins, in diameter, the shoes being expanded by Westinghouse air-brake cylinders.

With regard to the 2-ton model, which is known as the W20, this is designed to carry a gross load of 52 cwt.

The engine has four cylinders of 31-in. bore and 5-in, stroke, giving a maximum of 41 b.h.p. at 2,200 r.p.m. The pistons are of aluminium alloy, and the cylinder head is also of aluminium.

One improvement is in connection with the lubrication, the oil now being supplied under pressure to the main bearings and to the big-end troughs.

The engine and gearbox form a unit with a central change and a power takeoff. The gearbox is entirely new.

There is •a single-plate dutch 11 ins. in diameter.

In this chassis the brakes are all on the rear wheels. Each "shoe" is a steel band with a floating fulcrum and faced with friction fabric.

A rubber trunnion sleeve forms the single-point mounting at the front of the engine-gearbox unit. The two points of attachment for the bell housing are also on rubber.

The wheels themselves run on Bock taper-roller bearings. Oilless bushes are use.T for the cross-shafts and certain other points which are so often neglected. The propeller shaft has Spicer universal joints.