A REMARKABLE CHASSIS FROM SWITZE LAND.

Page 106

Page 107

Page 108

If you've noticed an error in this article please click here to report it so we can fix it.

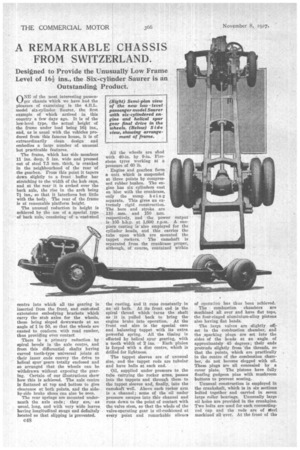

Designed to Provide the Unusually Low Frame Level of 161ins., the Six-cyliOer Saurer is an Outstanding Product.

O■ of the most interesting passenger chassis which we have had the pleasure of examining is the 4.B.L. model six-cylinder. Saurer, the first example of which arrived in this country a few days ago. It is of the low-level type, the actual height of the frame under load being 16i. ins., and, as is usual with the vehicles produced from this famous house, it is of extraordinarily clean design and embodies a large number of unusual but practicable features.

The frame, which has side members 11 ins. deep, 5 ins, wide and pressed out of steel 7.5 mm. thick, is cranked in the neighbourhood of the rear of the gearbox. From this point it tapers down slightly to a front buffer bar stretching to the width of the hub caps, and at the rear it is arched over the back axle, the rise in the arch being 7i ins., so that it interferes but little with the body. The rear of the frame is at reasonable platform height.

The unusual reduction in height is achieved by the use of a special type of back axle, consisting of a cast-steel centre into which all tne gearing is inserted from the front, and cast-steel extensions embodying brackets which carry the stub axles for the wheels, these being sloped downwards at an angle of 1 in 50, so that the wheels are canted to conform with road camber, thus providing even contact There is a primary reduction by spiral bevels in the axle centre, and from this differential shafts having curved tooth-type universal joints at their inner ends convey the drive to helical spur gears totally enclosed and so arranged that the wheels can be withdrawn without exposing the gearing. Certain of our illustrations show how this is achieved. The axle centre Is flattened at top and bottom to give clearance at both points, and the sideby-side brake shoes can also be seen.

The rear springs are mounted underneath the axle ends; they are, as usual, long, and with very wide leaves having longitudinal snugs and definitely located so that slipping is prevented. II the wheels are shod with 40-in. by 9-in. Firestone tyres working at a preisure of 60 lb.

ngine and gearbox form a Init which is suspended at three points by compresrubber bushes. The en

has six cylinders cast bloc with the crankcase, the sump being rate. This gives an exely rigid construction.

bore and stroke are sed gin en on sep tre Th mm. and 150 ram. respectively, and the power output is 105 b.h.p. at 1,600 r.p.rn. A onepiece casting is also employed for the cylinder heads, and this carries the tu upon which are mounted the et rockers. The camshaft is rated from the crankcase proper, ough, of course, contained within

the casting, and it runs constantly in an oil bath. At its front end is the spi al thread which turns the shaft as it is. pulled back to bring the en ne brake into operation. At the fro it end also is the special cam and balancing tappet with its extra po erful spring. All the timing is off ted by helical spur gearing, with a toth width of 2 ins. Each pinion is gorged with a disc centre, which is dr" led for lightness.

e tappet sleeves are of unusual siz , and the tappet rods are tubular an have balls at each end.

il, supplied under pressure to the tube carrying the rocker arms, passes into the tappets and through them to the tappet sleeves and, finally, into the canlishaft well. Above each rocker arm is a channel; some of the oil tinder pressure escapes into this channel and runs down to the point of contact with the valve stem, so that the whole of the valve-operating gear is oil-cushioned at ev ry point and remarkable silence

of operation has thus been achieved.

The combustion chambers are machined all over and have flat tops, the four-ringed aluminium-alloy pistons also having flat beads.

The large valves are slightly offset in the combustion chamber, and the _sparking plugs are set into the sides of the heads at an angle of approximately 45 degrees; their ends protrude slightly from 'the threads, so that the points, which are practically in the centre of the combustion chamber, do not become clogged with oil. These plugs are all concealed by a cover plate. The pistons have fully floating gudgeon pins with mushroom buttons to prevent scoring.

Unusual construction is employed in the crankshaft, which is in six sections bolted together and carried in seven large roller bearings. Unusually large. oil holes aro provided in the crankpins. Two bolts are used for each connectingrod cap and the rods are of steel machined aLl over. At the front of the

crankshaft is a. vibration damper, consisting of two discs pressed apart by coil springs and bearing against two rings of friction fabric, one secured to the main plate on the crankshaft and the other to a ring bolted to this plate. 'Reverting to the valve gear, coil:. springs on the rocker shaft perform the

two functions of silencing the rockers and ensuring their constant contact with the tappets.

Circulation of the lubricating oil is effected by a gear-type pump which is not immersed. At points where the oil supply is not under pressure, lubrication is effected by providing channels in the crankcase to catch the oil and convey it wherevet required.

The cooling is particularly efficient. The water jackets, which are of unusual capacity, are carried down the full length of the piston stroke. Circulation of the water is effected by centrifugal pump mounted at the front of the timing case and bolted direct to it, there being no eXternal Pipes, as water

passages are cored into the cover. There is a single accessible gland.

Behind the timing case at the off side is a Scintilla dynamo and magneto unit, which is •carried in a curved bracket east in One with the crankcase. The unit provides automatic advance of the ignition. There is also a Scintilla electric starter at the off side. The fan is driven direct from the timing gears through the medium of a friction clutch.

-Despite its power, the engine is most compact ; this compactness applies, as a matter of fact, to the whole enginegearbox unit.

The clutch is a multiple dry-plate type with fabric friction material.

The gearbox provides four speeds forward and a reverse. It has central control, the whole of the selector mechanism being carried on the top cover. On the rear cover is mounted a neat tyre pump, the control handle of

which is arranged to pass .through the floorboards, close to the driver. The first cardan joint of the propeller shaftk is enclosed in the back of the gearbox. This Mad the other two joints are of the fork-and-pinion type, completely enclosed and arranged with sunken f-lt washers pressing against spherical faces on. the star pieces, thus preventing all loss of lubricant. •

In a central eross-member of the frame is a casing containing the selialigning ball bearing for the shaft, and the rear portion of the shaft takes the form of a stout tube.

Front-wheel brakes are provided as standard. The drums are hidden withiu the wheels and the shoes are operated in a very simple manner by curved levers passing up through holes in the axle forks. All the brakes are totally. enclosed. The front brakes and one set of rear brakes arc operated by pedal, and the second set of rear brakes by hand lever. The two brake cross-shafts are mounted. at each end in a single bracket which forms an oil reservoir filled by a single Tecalemit lubricator. The brakes are not compensated, but each cross-shaft is divided, one-11W being splined into a sleeve, and this sleeve allows a certain amount of flexion under torsional stresses.

An important point in connection with the springs is that coMpressedrubber bushes are 'employed for the —Shackles, this rubber being protected from grease and water. Rubber blocks are also employed at each side of the balls in the steering joints, whilst rubber rings prevent the entry of water and dirt.

This is a good example of the fact that rubber is more and more being used in chassis assembly as a means of cushioning parts that otherwise might set up chatter and Other objectionable _noises.

Every attention has been given to providing easy and efficient weans for adjusting the brakes, pedals, etc. Each

brake rod is formed in 071e, with a balance weight which prevents it turning under vibration and serves as ft handle by which it can be rotated for adjustment. The clutch pedal also has a screw stop to prevent excessive movement

Provision is made for the driving of a speedometer from the gearbox.

The following are the main dimen sions and particulars :—Wheelbase, 19 ft.; body space (from dash to end of frame), 24 ft. 7 ins.; overall length, 29 ft. 13 ins.; track (front), 5 ft. 101 ins.; (rear), 5 ft. 7i ins.; diameter of turning circle, 54 ft.; road clearance (front), 81 ins.; (rear), 91 ins.; maximum width (front), 7 ft. 21 ins.; (rear), 7 ft. 5 ins.; chassis weight, 3 tons 14 cwt.