SUSPENSION'S the Thing !

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

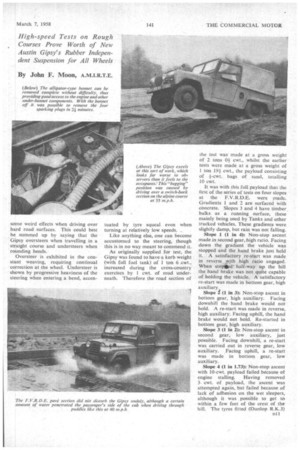

BEARING in mind the unusual feature of all-independent suspension, embodying rubber in torsion, my first thought when I accepted the offer of a new Austin Gipsy 4 x 4 general-purpose vehicle for test was to take it over the F.V.R.D.E. suspension course and Bagshot Heath rough track.

A full day was spent in doing so and the vehicle showed itself to have one of the finest suspension systems ever designed for this class of work, with the possible exception of some expensive and specialized layouts designed for a specific purpose.

The suspension is advantageous not only to the driver and pasSenger, who find themselves travelling over the roughest ground at surprisingly high speeds without noticeable ill effects, but also in respect of the general usefulness of the vehicle. It ensures that for the most part all four wheels stay on the ground and thus each is able to contribute towards propulsion.

In other respects the Gipsy is typical of other f-ton vehicles of this type. Its finish makes no pretence at providing car luxury; its appearance is purely functional, and its driving characteristics provide a constant reminder that this is essentially a robust crosscountry vehicle.

The model offered for test was powered by the B.M.C. 2.199-litre o.h.v. petrol engine, which has net torque and horse-power ratings of 110 lb.-ft. and 62 b.h.p. respectively. This engine gives a maximum road speed of 63 m.p.h., good acceleration and adequate hill-climbing performance.

Fully described and illustrated in The Commercial Motor last week, the Gipsy's most important feature is the

D10 use of Spencer Moulton Flexitor torsional rubber suspension units, each wheel being suspended independently on trailing arms. As was shown on test, this gives a smooth ride with no undue bouncing, partly because of the self-damping effect of the rubber bushes, helped by the use of telescopic dampers at the rear and lever-type dampers at the front.

A peculiar effect produced by the use of trailing arms at the front is the large changes in caster angle between full-bump and rebound positions of the wheels. For instance, when the wheels are deflected from full rebound to full bump, the caster angle changes • from 17° positive to 10' negative, the overall wheel deflection being 6 in.

Although this does not noticeably influence the steering characteristics when on rough ground, it produces some weird effects when driving over hard road surfaces. This could best be summed up by saying that the Gipsy oversteers when travelling in a straight course and understeers when rounding bends.

Oversteer is exhibited in the constant weaving, requiring continual correction at the wheel. Understeer is shown by progressive heaviness of the steering when entering a bend, accen

tuated by tyre squeal even when turning at relatively. low speeds. _

Like anything else, one can become accustomed to the steering, though this is in no way meant to commend it.

As originally supplied for test, the Gipsy was found to have .a kerb weight (with full fuel tank) of 1 ton 6 cwt., increased during the cross-country exercises by 1 cwt. of mud under neath. Therefore the road section of the test was made at a gross weight of 2 tons 0-1cwt., whilst the earlier tests were made at a gross weight of 1 ton 191 cwt., the payload consisting of 1-cwt. bags of sand, totalling 10 cwt.

It was with this full payload that the

• first of the series of tests on four slopes at the F.V.R.D.E. were made. Gradients 1 and 2 are surfaced with concrete. Slopes 3 and 4 have timber. balks as a running surface, these mainly being used by Tanks and other tracked vehicles. These gradients were slightly damp, but rain was not falling.

Slope 1 (1 in 4): Non-stop ascent made in second par, high ratio. Facing down the gradient the vehicle was stopped and the hand brake just held it. A satisfactory re-start was made in reverse with high ratio engaged. When stoPar.dhalf-way up the hill the hand brake was not quite capable of holding the vehicle. A satisfactory re-start was made in bottom gear, high auxiliary..

Slope 2 (1 hi 3): Non-stop ascent in bottom gear, high auxiliary. Facing downhill the hand brake would not hold. A re-start was made in reverse, high auxiliary. Facing uphill, the hand brake would not hold. Re-started in bottom gear, high auxiliary.

Slope 3 (1 in 2): Non-stop ascent in second gear, low auxiliary, just possible. Facing downhill, a re-start was carried out in reverse gear, low auxiliary. Facing uphill, a re-start was made in bottom gear, low auxiliary.

Slope 4 (1 in 1.73): Non-stop ascent with 10-cwt. payload failed because of engine stalling. Having removed 3 cwt. of payload, the ascent was attempted again, but failed because of lack of adhesion on the wet sleepers, although it was possible to get to within a few feet of the crest of the hill. The tyres fitted (Dunlop R.K.3)

had a semi-road tread: had full crosscountry tread tyres been fitted wheelspin would still have occurred, because of reduced tyre-ground contact area.

After these climbs, which showed the Gipsy to have a reasonably adequate performance for its class, it was taken on to the suspension courses.

There are three of these, each being 500 yd. long. The first course tackled was the pavd section, the surface of which was much more severe than that at the Motor Industry Research Association's proving ground. Normally it is difficult to maintain a steady speed much higher than 20 m.p.h. over this course, but the Austin was taken down it several times at more than 40 m.p.h. without difficulty.

Even with the full 10-cwt. load the ride was not appreciably rougher than with the 7-cwt. load, and the only illeffects after a dozen or more trips down the pave were the loosening of the rubber plug in the floor which gives access to the gearbox dipstick, and the loss of a hub cap.

40 m.p.h., Hands Off

The Gipsy was then taken over the 1-in,-1---in-sett track, consisting of blocks of concrete transversely spaced at irregular intervals. I was able to keep to 40 m.p.h. with my hands clear of the steering wheel. Having tested various vehicles over this track I would never have believed that I could have done this with anything other than some of the specialized Army equipment. The ride over these setts was little rougher than over normal roads.

The third test was over the setts. The Gipsy was taken many times over this track at 30 m.p.h. both with full load and part-load, and remained perfectly stable. Although, naturally, travel could not be termed smooth, it was much more comfortable-than in any other vehicle I have taken4rer the same ... course.

Deep puddles in • the hollows of the pave course raised large fountains when traversed at speed, and, a good deal of water entered the floor boards on the passenger side and through tile gaps in the side screens and the scuttle ventilator flap.

For the tests over the Bagshot Heath alpine course, the payload was reduced to 5 cwt., but tyre pressures were not lowered from their normal 20 p.s.i. at the front and 34 psi. at the rear.

Admirable Behaviour

The Gipsy behaved admirably, no matter what obstacles it was asked to surmount, and although the ground was extremely sticky and deeply rutted because of the steadily falling rain, rarely was it necessary to make more than one assault on any of the gradients, some of which went up to 1 in 2 severity. Indeed, I found the use of four-wheel drive unnecessary for the most part, because of the good adhesion of the independently sprung rear wheels.

The steering behaved well over this sort of surface and it was possible to "aim " the Austin with reasonable accuracy even on mud and slime. Although some deep stretches of water were passed through at speed and the crew got thoroughly soaked (because the hood was rolled back), the extended front wing valance effectively protected the ignition from a drenching. At the end of the test the engine and other under-bonnet components were liberally caked with mud, but the engine performance did not falter. Adrriittedly, when stopping on steep gradients it did not idle particularly well and it was reluctant to start on several occasions.

Carrying out the " jump " test, during which I tried to get all four wheels off the ground, an unfortunate landing from a height of about 3 ft. on the off-side front wheel caused the right track-rod section and the right damper linkage to bend badly. This left the Gipsy with no left lock at all, but the defect was not difficult to rectify, the rod being taken off and bent back to its proper shape in the cold state.

Steering Rods Slender

All the steering rods look a little frail for this type of vehicle and the results of this test, although it was severe, might well be repeated under strenuous conditions overseas.

Apart from damage to the steering and front damper the total harm caused by the alpine test added up to a lost bolt from the exhaust system intermediate bracket, a bad leak from the air-cleaner filter bffl and a broken steering-wheel boss cap.

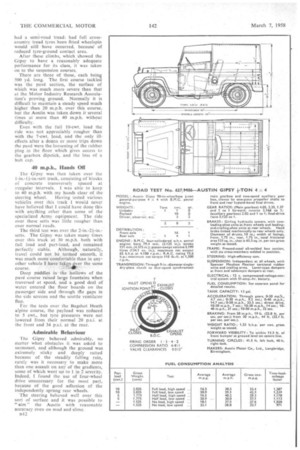

When the vehicle had been cleaned up it was put through the road section of he test, the results of which are detailed in the accompanying data panel. The fuel-consumption figures quoted were taken over a six-mile undulating course and a test tank was used to give maxi mum accuracy. Runs were made at 30-35 m.p.h. and 50-55 m.p.h. with varying payloads.

Acceferation, both through the gears and in direct drive, was excellent. The engine, having a long stroke, has good low-speed torque characteristics, which enable it to pull away smoothly in direct drive from 8 m.p.h.

Effective Cooling

A temperature-rise test made up the 1-mile 1-in-101 Bison Hill in an ambient temperature Of 46°F. increased the engine-coolant temperature by only 12°F., the final reading being 178°F. This climb occupied 2 minutes 10 seconds and the lowest gear used—second—was engaged for only 15 seconds.

Another test made down this hill in neutral at 20 m.p.h. showed negligible brake fade and there was no appreciable increase in pedaltravel. Moulded facings are fitted as standard. Satisfactory braking figures were obtained with cold drums and, principally because of the suspension characteristics, there was no undue wheel locking, as normally occurs with vehicles of this weight. • Hand-brake performance was somewhat disappointing, the best figure obtainable on the Tapley meter when applying it hard from 20 m_p.h. being 14 per cent. Immediately before this test I had adjusted the rear brakes, these being quick to wear and requiring frequent attention.

Other than the curious steering characteristics the Gipsy handles reasonably well on the road. The clutch and brake pedals require rather more pressure than one would expect on a vehicle of this size and the efficient synchromesh mechanism in the gearbox demands a fair amount of pressure to change gear. Gear-lever travel is short and direct.

'The hand-brake lever is awkwardly placed beneath the driver's left leg and does not come readily to hand. There are two driving mirrors mounted welh forward on the front wings, but need longer stalks, as it is difficult to see them through a clear windscreen and almost impossible to see even the off-side one when it is raining.

The full-width three-piece bench, seat is comfortable, but tall drivers found the driving Position somewhat cramped. The centre passenger sits astride the large transmission cowl, but his presence does not hamper gear changing.

A certain amount of heat penetrates into the cab from the floorboards and front bulkhead, which are not insulated. The loose-fitting side screens and the signalling flaps in them, which cannot be secured, cause a strong draught above waist level. For use in hot weather there is a small ventilating flap beneath the windscreen, although I doubt whether it is sufficiently large to have much effect other than to let. inthe rain.

Cables for Door Locks The cab door locks are controlled by Bowden cables on the inside, the doors being opened from outside by reaching through the signalling flaps. These cables do not look particularly robust and care must be taken to ensure that the outer cover does not jam in the lock housing: if this happens the lock does not work.

Other criticisms concern the method of attaching the side screens, which are held to the doors by studs with hexagon nuts. Barrel-type wing nuts could be used to simplify removal of the screens.

The transmission is commendably quiet for a vehicle of this type and the engine also works quietly at normal speeds, although the exhaust note is raucous. The hood fits well, is simple t6 remove and detach., and the side and rear portions can be rolled up and secured in place. Amber flashing direction indicators are fitted at front and rear. The 13-gal.. fuel tank has a widenecked filler on the left of the vehicle, which facilitates filling from cans or fastflowing pumps.

Maintenance tests conducted on the Gipsy show it to be generally good in this respect. Although there are six propeller shafts, each with three grease nipples, other greasing has been reduced to only four points on the steering swivels, the other steering joints having nylon bushes which do not require lubrication.

Raising and propping open the bonnet takes 13 seconds and removal of the bonnet complete, 26 seconds. With the bonnet off I checked the water level in 6 .seconds and the engine-oil level in 14 seconds.

To detach the air-cleaner filter bowl to inspect the level I had to turn the front wheels on to right lock because the drop-arm obstructed movement of the bowl when the wheels were straight ahead. Otherwise there is nothing difficult about checking the air-cleaner oil level and I completed the task in 1 minutes.

The clutch and brake master cylinders have integral reservoirs and the cylinders are mounted side by side on the front bulkhead, checking the level in both taking only 14 seconds. • I then removed the four sparking plugs in 2:1. minutes and after cleaning them replaced them in 1 minute 35 seconds. Next I checked the make-and-break gap in 11 minutes, using the starting handle to turn over the engine. This concluded the under-bonnet jobs and I was then able to replace the bonnet single-handed in just over 1 minutes.

Oil Level Checks

Further oil level checks included that of the main gearbox, for which a dipstick is provided. This can be reached hy removing the rubber plug in the cabfloor transmission housing. A dipstick is also provided in the transfer gearbox, which has a separate oil system from the main gearbox. The stick is reached by removing the centre cushions and opening a hinged trap in the seat box.

spent 1 minute 5 seconds checking this level, a certain amount of time being wasted in locating the clips which secure the seat cushions to the rail at the back of the seat box.

Square-socketed combined filler and level plugs are provided in the front and rear differential housings and it takes a minute to check the oil levels in each of these, I then spent 13 minutes adjusting the four brakes, each wheel being jacked up individually by the screw jack in the tool kit. There .are two hexagonal external adjusters to each front brake, and one square-headed external adjuster for each rear brake.

The battery is reached by removing the driver's seat cushion and the seat-box lid, the latter being secured by four Darts fasteners. Checking these levels took 2 minutes.

Fuse Change Easy A fuse change proved to • be simple, because the fuses are housed in a hinged .panel in the instrument cluster. Opening this panel.also gives access to the lighting wiring. A fuse change, therefore, took only 11 seconds, and, of course, can be done without leaving the cab.

As a final task I was able to remove the spare wheel in ,25 seconds and stow it again in 32 secomk. A spare wheel is provided as standard equipment and is carried in the boot, clamped to the front boards immediately behind the centre seat: there is no alternative stowage position.

All these tasks were carried out with the standard tool kit, which is particularly comprehensive, including, amongst other things, two screwdrivers—one for slotted screws and one for Phillips-headed screws.