Latest Lacre Features.

Page 5

Page 6

Page 7

If you've noticed an error in this article please click here to report it so we can fix it.

Large Sales and Good Delivery.

Since cur last visit to the Lacre Co.'s new works, at Letchworth, remarkable progress towards production on a large scale has been imele, and we were pleased to nab numbers of chassis approaching completion, or under test upon the road. In all the different departments of the works, great activity was evident, and the operations of the machining, fitting arid assembling of the various detail; and units were proceeding apace. The equipment of this company's new works comprises many fine machine tools, and these come from the best of British and American builders. If we may judge by the excellence of the up-to-date machines installed, Mr. Claude Browne, the managing director of the Lacre Co., does not intend to place much reliance upon the labours of his bench hands, although skilled men are employed in this as well as in all other departments of the factory.

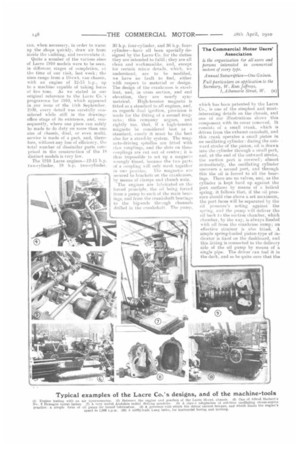

We were particularly satisfied to note so many British-built machines in the works, and, for stiffness of construction, they will take a lot of beating. In the old days, when the majority of machine details were made of east iron, and tool .steel was the hardest material then in use, the lightly-built American and German machine tools of that period were—so far as speed and efficiency were concerned—far ahead of the home pmducts; but, with the advent of motor vehicles, and the high-grade alloy eteels which followed in their wake, more-rigidly-built high-speed machines were demanded, and British tool makers have not lagged behind their foreign competitors in the production of suitable machines. Amongst the makers represented in the Lacre factory are: J. Arebdade and Co., Ltd., of Birmingham ; Alfred Herbert, Ltd., of Coventry; Messrs, John Lang and Sons, of Johnstone; and Geo. Richards and Co., Ltd., of Broadheath. Examples from the Providence works of the .Brown and Sharpe Manufacturing Co., of the U.S.A.., are also " on the belt," and are doing good work. We would especially direct our readers' attention to the accompanying illustrations of genie of the machines is hich the Lacre Co. has laid down. The light radial-drilling machine, by Archdale, for instance, is a tool that may be used for a large number of purposes, such es drilling, tapping, fac

ing, lighi; be etc., whilet, for heavy work, the horizontal turningand-boring lathe, by John Lang, will well sustain the reputation of that Scottish maker. The head of the latter machine is provided with an infinitelyvariable-speed gear, and is driven by a single belt from a constant-speed overhead colintershaft.

The " medium " standard of limit gauges, as recommended by the British Engineering Standards Committee, hoe been adopted in these works, and all the gauges are of the well-known Newell type, made by Peter Hooker, Ltd., of Black Horse Lane, Walthamstow. As in the matter of " fits," so also in respect of the

quality of materials, the Lacre Co. has taken the British Engineering Standards Committee's ruling as its guide, and all castings, rolled bars, channels, sheets, plates, rivets, 'bolts, etc., must not fall below the minimum set for railway rolling-stock. Such parts as crankshafts, gearbox shafts, and other stress-bearing parts are, however, ot much higher-grade material than that specified for rolling-stock, and nickelchrome, or chronie-vanadium steels are generously employed. Every third shaft or axle has turned en it a test piece, which is subsequently tested to destruction, and the results thus oh te are compared with the specification set down by the engineering department; occasional microscopic and chemical analyses of the materials are also made, and every precaution is taken to insure uniformly-high quality of the materials employed.

Every detail on the chassis bears en identification number, and, in the general stores, similarly-numbered wooden or steel bins are provided for the storing of such numbered parts— in readiness for issue either to the erectors, or to customers to replace parts worn out or damaged by accident or carelesenees.

Of the buildings themselves, we tneed write nothing in this article ; they were illustrated and described in -air issue of the 20th January. They are, however, most-effectively heated by clean fresh air, which is drawn from above the shop roof, through a vertical shaft, by means of a large centrifugal fan; the air is forced through a heating chamber, aad is thence distributed ee all parts of the buildings through overhead galvanized-iron pipes. The heating chamber is provided with a number of radiators, anti these are heated by low-pressure steam from a separate boiler. The heater was installed by Sutcliffe, of Manchester. It

can, when necessary, in order to warm up the shops quickly, draw air from inside the building, and re-circulate it. Quite a number of the various sizes of Lacre 1910 models were to be seen, in different stages of completion, at the time of our visit, last week; the sizes range from a 10-ewt. van chassis, with an engine of 12-15 h.p., up to a machine capable of taking loaus ot five tons. As we stated in our original reference to the Lacre Co.'s programme for 1910, which appeared in our issue of the Itith September, If.:09, every detail was carefully considered while still in the drawingoffice stage of its existence, and, eonsequently, where one piece can safely be made to do duty on snore than one size of chassis, dual, or even multi, service is made of a part, and, therefore, without any loss of efficiency, the total number of dissimilar parts comprised in the construction of the IS distinct models is very low.

The 1910 Lacre engines-12-15 h.p. two-cylinder, 18 11.1). two-cylinder. 30 h.p. four-cylinder, and 36 h.p. fourcylinder—have all been specially designed by the Lane Co. for the duties they are intended to fulfil; they are all clean and workmanlike, and, except for certain minor details, which, we understand, are to be modified, we have no fault to find, either with respect to material or design. The design of the crankcases is excellent, and, in cross section, and end elevation, they are nearly symmetrical. High-tension ningneto is fitted as a standard to all engines, and, as regards dual ignition, provision is made for the fitting of a second magneto; this company argues, and rightly too, that, if a high-tension magneto be considered best as a standard, surely it nmst be the best also for a stand-by system. The magneto-driving spindles are fitted with claw couplings, and the slots on these couplings are cut out of centre ; it is thus impossible to set up a magneto wrongly timed, because the two parts of a coupling will only mesh together in one position. The magnetos are secured to brackets on the crankcases, by means of clamps and thumb nuts. The engines are lubricated on the • forced principle, the oil being forced front a pump to earl of the main bearings, and from the crankshaft bearings to the big-ends through channels drilled in the crankshaft. The pump,

which has been patented by the Lacre Co., is one of the simplest and mostinteresting details on the chassis, and one of our illustrations shows this component with its cover removed. It consists of a small crank, which is driven from the exhaust camshaft, and this crank operates a small piston in an oscillating cylinder : during the ont• ward stroke of the piston, oil is drawn into the cylinder through a small port, 'and, at the end of the outward stroke, the suction port is covered ; almost immediately, the oscillating cylinder uncovers a second port, and through this the oil is forced to all the bearings. There are no valves, and, as the cylinder is kept hard up against the port surfaces by means of a helical spring, it follows that, if the oil pressure should rise above a set maximum, the port faces will be separated by the oil pressure's acting against the spring, and the pump will deliver the oil back te the suctiou chamber, which chamber, by the way, is always flooded with oil from the crankcase sump; an effective strainer is also fitted. A simple spring-loaded piston-type of indicator is fixed on the dashboard, and this fitting is connected to the delivery side of the oil pump by means of a single pipe. The driver can feel it in the dark, and so be quite sure that the

oil is circulating ; in the daytime, lie can see it quite easily.

Each engine is provided with a simple, yet sturdy governor, which is located in the lower part of the crankcase and only comes into operation when the speed of the engine reaches 1,000 r.p.m., above which speed it is not possible to drive the engine. The governor is inaccessible to the driver, who cannot, therefore, tamper with it in any way ; too often, unfortunately, drivers are tempted to " adjust" an expesed, or accessible goveruor, so that it is really thrown out 01 action and the engine may be raced. Each engine is tested, with its own petrol tank and radiator, on one of the benches in the testing department, and the power is absorbed, during such test, by means of an air-dynamometer.

A leather-faced cone clutch of ample bearing surface, and a compact form of spring-drive coupling, connect the engine to the gearbox. The arrangement is clearly shown in one of our illustrations, whilst another view gives the details of the spring-drive coupling. The gearboxes on all Lacre models are simple in design, and robust in construction ; with the exception of the first and reverse speeds, the gears are of the always-in-mesh type, actuated by dog clutches. Three forward speeds are provided, for all models up to and including the twoton chassis, and, for all larger machines, four-speed boxes are fitted. All the gear wheels are made of heattreated nickel-chrome steel. The differential gear is mounted on the tail end of the gearbox mainshaft, and each chain-sprocket shaft is driven by a pair of bevel gears. Practically the same arrangement of transmission is adopted throughout the complete range of this maker's models, but, of course, the sizes and gear ratios of all the gears are modified to suit the imposed loads. All the brakes are provided with easy and positive forms of adjustment by hand, without the need for tools; all wearing parts, such as shoes, are easily renewable. All spring-shackle pins, etc., are fitted with suitable means ot lubrication. Rolled-steel channel frames are employed, and these are stiffly braced and gusseted. The back-axle radius rods, and the wheel-brake anchor rods, are provided with vulcanized fibre bushes and washers, and we are informed by the Lam Co. that long experience with machines having radius rods so fitted has shown that fibre wears much better than bronze under the prevailing conditions of mud and dust ; it also helps to eliminate noise and rattle. The Lacre Co.'s unique experience has enabled it fully to appreciate the arduous conditions which commercial motors have to fulfil, and its vehicles have been designed accordingly, having regard, also, to simplicity of construction, accessibility of parts, and the durability of each machine.

Letchworth, as a manufacturing centre, is daily attracting more attention from the heads of engineering concerns, and particularly from those interested in the motor industry. It enjoys the benefits of an excellent train service, with cheap fares to London every day of the week, and the surrounding country is admirably suited for the making of road tests. Suitable accommodation, in the way of workmen's residences, with large gardens, is now available, and Mr. W. H. Gaunt, the manager of the estate, assures us that more will be erected as is found necessary.