Contributions from Drivers and Mechanics.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY for the Best Communication Received, and One Penny a Line of ten words for any thing else published.

Drivers of commercial-motor vehicles and Ira tors, and mechanics and foremen of garages or shops, are invited to send short contrioutions on any subject ivhich is likely to prove of interest to our readers. Workshop tips and smart repairs ; long and successful nuns; interesting photographs : all ore suitable subjects. Send a post-card, or a letter, Of a sketch to us—no matter h w short, or how written, or how worded. We will "knock it into shape" and prepare sketches, where necessary, before pu'dication. The absence of a sketch d ■es nbt disqualify for a prise. When writing use one side of the paper only and men ion your employer's mime as a guarantee of bona fides. Neither your own nor your employer's name will be disclosed. Payment will be made immediately after publication. Address your letters to The Editor, T COMMERCIAL MOTOR, 7-15. Roseherv Avenue, London, E.C.

We require the full names and postal addresses of two correspondents who sign letters, which have reached this office, " Fuzzy " (Birmingham) and " K.K.K." (Acton) respectively.

A Repair to a Feed Pipe.

[728] " E.S." (Victoria l'ark) writes :—" In response to your invitation on the 'D. and M.' pages, I am sending you an account of a temporary repair which I effected some time ago to an injector feed-pipe. At the time of which I am writing my injector was the only reliable means I had of keeping the boiler supplied with water, so that, u-hen one day, whilst on a journey, the injector refused to pick up, although the tank was nearly three-parts full of water, I had to take the first opportunity of remedying the cause of the trouble. I completed my journey by the use of the pump, and then started to explore the inside

of the water-Lank. I found that the feed-pipe had broken off short at the flange inside the tank, and, as I

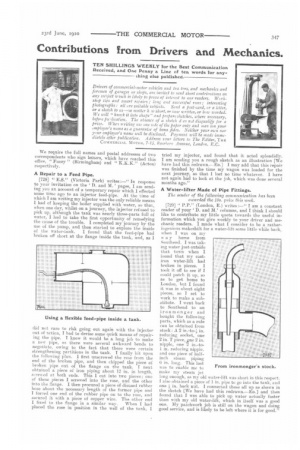

did not care to risk going out again with the injector out of action, 1 had to devise some quick means of repairing the pipe. I knew it would be a long job to make a new pipe, as there were several awkward bends to negotiate, owing to the fact, that there were certain strengthening partitions in the tank. I finally hit upon the following plan. I first unscrewed the rose from the end of the broken pipe, and then chipped the piece of broken pipe out of the flange on the tank. I next obtained a piece of iron piping about 12 in. in length, screwed at both ends. This I cut into two pieces ; one of these pieces I screwed into the rose, and the other into the flange. I then procured a piece of disused rubber hose about the necessary length of the former pipe and I forced one end of the rubber pipe on to the rose, and secured it with a piece of copper wire. The other end I fixed to the flange in a similar way. When I had placed the rose in position in the well of the tank, I tried my injector, and found that it acted splendidly. I am sending you a rough sketch as an illustration [We have had this redrawn.—En.] I may add that this repair was finished by the time my wagon was loaded for the next journey, so that I lost no time whatever. I have not again had to look at the job, which was done several months ago."

A Water-lifter Made of Pipe Fittings.

The sender of the following communication has been awarded the 10s. prize this week.

[729] " P.P." (Landon, E.) writes :—" I am a constant reader of your D. and M.' columns, and I think I should like to contribute my little quota towards the useful information which you give weekly to your driver and mechanic readers. I made what I consider to be a ratheringenious makeshift for a water-lift. some little while back, Irlien I was on my w a y home from Southend. I was taking water just outside that town when I found that my eastiron water-lift had broken in pieces. I took it off to see if I could patch it up, so as to get home to London, but I found it was in about eight pieces, so I set to work to make a substitute. I went back to Southend to an ironmonger and bought the following parts, which as a rule can be obtained from stock : A 2 in.-to-,!, in. reducing socket, one 2 in. T piece,sne 2 in. nipple, one .2 in.-to1 in. reducing nipple. and one piece of halfinch steam piping 6 in. long. This last was to enable me to make my steam jet long enough, as my old water-lift was short. in this respect. I also obtained a piece of 1 in. pipe to go into the tank, and one .1. in. back nut. I connected these all up as shown in the sketch [We have had this redrawn.—En.] and then found that I was able to pick up water actually faster than with my old water-lift, which in itself was a good one. My patchwork job is still on the wagon and doing good service, and is likely to be left where it is for good." From ironmonger's stock.