MAKE DO AND MEND

Page 96

Page 98

If you've noticed an error in this article please click here to report it so we can fix it.

When money is tight refurbishing will often provide a bodybuilder with welcome income. We ask manufacturers how much the present recession has prompted their customers to make do and mend.

• Refurbishing has always been a welcome standby for bodybuilders. At times when operators are unwilling to buy new, the idea of updating existing equipment can seem attractive.

The refurbishing of semi-trailers has been given a boost by the shift away from open platforms and towards enclosed bodies — usually curtain-siders. Through the 1980s, a constant stream of flat trailers was being sent to bodybuilders for conversion, bringing useful fill-in business to a volatile market.

STRAW POLL

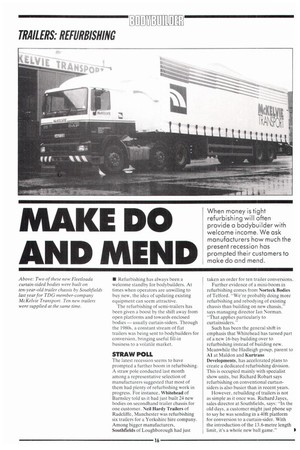

The latest recession seems to have prompted a further boom in refurbishing. A straw pole conducted last month among a representative selection of manufacturers suggested that most of them had plenty of refurbishing work in progress. For instance, Whitehead of Barnsley told us it had just built 24 new bodies on secondhand trailer chassis for one customer. Neil Hardy Trailers of Radcliffe, Manchester was refurbishing six trailers for a Yorkshire hire company. Among bigger manufacturers, Southfields of Loughborough had just

taken an order for ten trailer conversions.

Further evidence of a mini-boom in refurbishing comes from Norteck Bodies of Telford. "We're probably doing more refurbishing and rebodying of existing chassis than building on new chassis,says managing director Ian Norman. "That applies particularly to curtainsiders."

Such has been the general shift in emphasis that Whitehead has turned part of a new 16-bay building over to refurbishing instead of building new. Meanwhile the Hadleigh group, parent to Al at Maldon and Kurtrans Developments, has accelerated plans to create a dedicated refurbishing division. This is occupied mainly with specialist show units, but Richard Robart says refurbishing on conventional curtainsiders is also busier than in recent years.

However, rebuilding of trailers is not as simple as it once was. Richard Jayes, sales director at Southfields, says: "In the old days, a customer might just phone up to say he was sending in a 40ft platform for conversion to a curtain-sider. With the introduction of the 13.6-metre length limit, it's a whole new ball game."

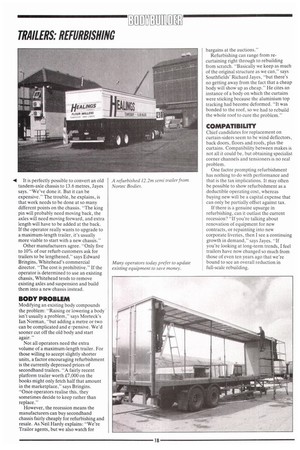

It is perfectly possible to convert an old tandem-axle chassis to 13.6 metres, Jayes says. -We've done it. But it can be expensive." The trouble, he explains, is that work needs to be done at so many different points on the chassis. "The king pin will probably need moving back, the axles will need moving forward, and extra length will have to be added at the back. If the operator really wants to upgrade to a maximum-length trailer, it's usually more viable to start with a new chassis."

Other manufacturers agree. "Only five to 10% of our refurb customers ask for trailers to be lengthened," says Edward Bringins, Whitehead's commercial director. "The cost is prohibitive." If the operator is determined to use an existing chassis, Whitehead tends to remove existing axles and suspension and build them into a new chassis instead.

BODY PROBLEM

Modifying an existing body compounds the problem: "Raising or lowering a body • isn't usually a problem," says Morteck's Ian Norman, "but adding a metre or two can be complicated and e•,:pensive. We'd sooner cut off the old body and start again."

Not all operators need the extra volume of a maximum-length trailer. For those willing to accept slightly shorter units, a factor encouraging refurbishment is the currently depressed prices of secondhand trailers. "A fairly recent platform trailer worth £7,000 on the books might only fetch half that amount in the marketplace," says Bringins. "Once operators realise this, they sometimes decide to keep rather than replace."

However, the recession means the manufacturers can buy secondhand chassis fairly cheaply for refurbishing and resale. As Neil Hardy explains: "We're Trailor agents, but we also watch for bargains at the auctions."

Refurbishing can range from recurtaining right through to rebuilding from scratch. "Basically we keep as much of the original structure as we can," says Southfields' Richard Jayes, "but there's no getting away from the fact that a cheap body will show up as cheap." He cites an instance of a body on which the curtains were sticking because the aluminium top tracking had become deformed. "It was bonded to the roof, so we had to rebuild the whole roof to cure the problem."

COMPATIBILITY

Chief candidates for replacement on curtain-siders seem to be wind deflectors, back doors, floors and roofs, plus the curtains. Compatibility between makes is not all it could be, but obtaining specialist corner channels and tensioners is no real problem.

One factor prompting refurbishment has nothing to do with performance and that is the tax implications. It may often be possible to show refurbishment as a deductible operating cost, whereas buying new will be a capital expense that can only be partially offset against tax.

If there is a genuine upsurge in refurbishing, can it outlast the current recession? "If you're talking about renovation of equipment for new contracts, or repainting into new corporate liveries, then I see a continuing growth in demand," says Jayes. "If you're looking at long-term trends, I feel trailers have now changed so much from those of even ten years ago that we're bound to see an overall reduction in full-scale rebuilding.