LIGHTER WITH

Page 100

Page 101

If you've noticed an error in this article please click here to report it so we can fix it.

Despite its relative complexity air suspension is growing in popularity. We look at some of the latest developments.

• There can be few operators who doubt the operational advantages of air suspension and it is specified on more than half of all new semi-trailers in the UK. Well designed air suspension gives very good load transfer between axles and a ride quality that is not only kinder to the cargo but to the vehicle itself.

Increased sales volumes have helped to bring down costs and a growing familiarity has reduced any resistance to what is inevitably more complex than the standard leaf spring it replaces. Its biggest deterrent, the weight penalty, is being attacked from all sides.

Following the changes in legislation which now allow combination lengths of up to 16.5m, Crane Fruehauf claims to have eliminated the weight penalty of adding air suspension to its longer length platform trailers without any reduction in strength that might lead to increased fatigue.

LIGHTER DESIGN

Because the company produces its own air suspension, it has been abie to make adequate allowance for it in its design. Using the latest CAD facilities and finite element analysis techniques Crane Fruehauf has produced a much lighter overall design, only previously achieved using much higher cost aluminium components.

While all trailer components came in for scrutiny, specific changes relating to the 'T' air suspension include relocation, which is said to improve operation and allow the introduction of a lighter plastic composite piston and the elimination of corrosion. Weight savings here, together with changes made to the main frame (with its new radiused neck profile) floor, side guards and mudwings, add up to about 400kg.

BPW, now residing in its new UK HQ on the Blaby Industrial Park in Leicestershire, is currently looking at ways to save weight in suspension design while improving axle damping still further without sacrificing reliability. As market leader throughout Europe in air suspended axles BPW takes a wider view of what is required in the modern operation which is reflected in its product range. This not only includes its latest fixed blade design but steered axles as well. Its Speedline alloy wheel, produced in Italy, is one of the more obvious ways to save about 22kg per wheel station. Other advantages include cooler running and improved road holding.

SELF-STEER

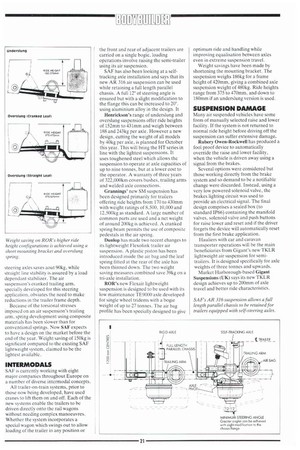

Self steering axles not only improve manoeuvrability but do so with reduced tyre wear. The oblique angle of the non steered wheels of a BPW tandem and triaxle design is less than for a rigid suspension, which also provides some benefit in tyre life. BPW's new lightweight and low maintenance self steering axles saves aout 90kg, while straight line stability is assured by a load dependant stabilizer. The air suspension's cranked trailing arm, specially developed for this steering application, obviates the need to make reductions in the trailer frame depth.

Because of the torsional stresses imposed on an air suspension's trailing arm, spring development using composite materials has been slower than for conventional springs. Now SAF expects to have a design on the market before the end of the year. Weight saving of 150kg is significant compared to the existing SAF lightweight system, claimed to be the lightest available.

INTERMODALS

SAF is currently working with eight major companies throughout Europe on a number of diverse intermodal concepts.

All trailer-on-train systems, prior to those now being developed, have used cranes to lift them on and off. Each of the new systems enable the trailers to be driven directly onto the rail wagons without needing complex manoeuvres. Whether the system incorporates a special wagon which swings out to allow loading of the trailer in any position or

the front and rear of adjacent trailers are carried on a single bogie, loading operations involve raising the semi-trailer using its air suspension.

SAF has also been looking at a selftracking axle installation and says that its new AR 316 air suspension can be used while retaining a full length parallel chassis. A full 12° of steering angle is ensured but with a slight modification to the flange this can be increased to 20°. using aluminium alloy in the design. It Henrickson's range of underslung and overslung suspensions offer ride heights of 152mm to 431mm and weigh between 188 and 243kg per axle. However a new design, cutting the weight of all models by 40kg per axle, is planned for October this year. This will bring the HT series in line with the lightest suspensions. It uses toughened steel which allows the suspension to operate at axle capacities of up to nine tonnes, but at a lower cost to the operator. A warranty of three years of 322,000km covers bushes, trailing arms and welded axle connections.

Grannings' new SM suspension has been designed primarily for trailers offering ride heights from 170 to 430mm with weight ratings of 8,500, 10,000 and 12.500kg as standard. A large number of common parts are used and a net weight of around 200kg is achieved. A cranked spring beam permits the use of composite pedestals in the air spring.

Dunlop has made two recent changes to its lightweight Flexolink trailer air suspension. A plastic piston has been introduced inside the air bag and the leaf spring fitted at the rear of the axle has been thinned down. The two weight saving measures combined save 39kg on a tri-axle installation.

ROR's new Flexair lightweight suspension is designed to be used with its low maintenance TE9000 axle developed for single wheel tridems with a bogie weight of up to 27 tonnes. The air bag profile has been specially designed to give optimum ride and handling while improving equalisation between axles even in extreme suspension travel.

Weight savings have been made by shortening the mounting bracket. The suspension weighs 186kg for a frame height of 420mm, giving a combined axle suspension weight of 480kg. Ride heights range from 375 to 470mm, and down to 180mm if an underslung version is used.

SUSPENSION DAMAGE

Many air suspended vehicles have some form of manually selected raise and lower facility. If the system is not returned to normal ride height before driving off the suspension can suffer extensive damage.

Rubery Owen-Rockwell has produced a fool proof device to automatically override the raise and lower facility, when the vehicle is driven away using a signal from the brakes.

Several options were considered but those working directly from the brake system and so demand to be a notifiable change were discarded. Instead, using a very low powered solenoid valve, the brakes lighting circuit was used to provide an electrical signal. The final design comprises a sealed box (to standard 1P66) containing the manifold valves, solenoid valve and push buttons for raise lower and reset and if the driver forgets the device will automatically reset from the first brake application.

Hauliers with car and caravan transporter operations will be the main beneficiaries from Gigant's new TKLR lightweight air suspension for semitrailers. It is designed specifically for axle weights of three tonnes and upwards.

Market Harborough-based Gigant Suspensions (UK) says its new TKLR design achieves up to 200mm of axle travel and better ride characteristics.