SWEEPING CHANGES BIG LEYLAND MODEI

Page 74

Page 75

Page 76

Page 79

If you've noticed an error in this article please click here to report it so we can fix it.

New Leyland Maximumcapacity Four-, Sixand Eight-wheelers Announced: Completely New Designs Have Many Interesting Features .• Rear engined Single decker

COMPLETELY new four-, sixand eight-wheeled heavy-duty goods vehicles are announced today by Leyland Motors, Ltd., Leyland, Lanes, to supplant the models which have been in production since shortly after the end of the war. Additionally, a new passenger model known as the Lion has been introduced: this is a rear-engined high-frame chassis for single-deck operation.

The goods vehicles are new from stem to stern. Briefly. their features include modifications of existing power unit, which now give greater outputs and better economy; a new five-speed gearbox, with sixand seven-speed versions; new brakes; new double-reduction driving axles; new rearbogie suspension arrangements; power-assisted steering and hand brake; and a new forward-entrance cab, as used on Albion Clydesdale and Chieftain vehicles, but which is available in steelor plastics-panelled forms.

Sir Henry Spurrier, chairman and managing director of Leyland Motors, Ltd., is stated to have directed personally the research work on the new power units. When announcing the vehicles, he said that, despite five years' development work on disc brakes, and air and hydraulic suspension systems, his engineers believed that these innovations were not ready yet and they had not been incorporated in the new range. Sir Henry added, however, that they could well appear during its life or that even better ideas—such as a brake that would never wear out— might be evolved.

The New Goods Range

THERE are five Beaver four-wheelers (14 tons gross), I five Hippo six-wheelers (20 tons) and five Octopus eight-wheelers (24 tons). The Beaver tractive unit, however, has a gross train weight rating of 24 tons. The Beaver models have wheelbases of 17 ft. 6 in., 15 ft. and 13 ft. 6 in. in the case of the general-haulage models; 12 ft. for the tipper chassis and 8 ft. for the tractive unit. The general-haulage Hippo and Octopus models share the same wheclbases-17 ft. and 14 ft. 9 in. in the case of both fourand two-spring rear-bogie versions. The Hippo tipper has a wheelbase of 12 ft. 6 in., whilst the Octopus tipper is based on the 14-ft. 9-in.-wheelbase chassis.

Matching Scamrnell rubberor air-sprung semi-trailers have been developed for use with the Beaver tractor, similar to the units detailed in last week's issue. These can have wedgeor cam-actuated brake units, either of which give a braking performance which is matched to

that of the tractive unit. A matched single-axle semitrailer for Super Comets has also been developed.

For the time being, at least, no changes are to be made to existing Super Beaver and Super Hippo normal-control models, whilst present passenger chassis are not affected. A new power unit has been developed for the Super Comet 14-ton-gross four-wheeler, however, this being a 400-cu.-in. oil engine with a net power output of 125 b.h.p. at 2,000 r.p.m.

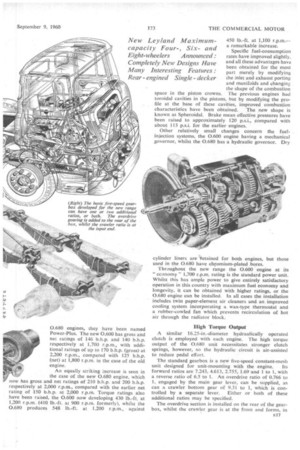

Perhaps the most import ant features of the new goods models are the engines. Because of the additional power obtained from both the 0.600 and

0.680 engines, they have been named Power-Plus. The new 0.600 has gross and net ratings of 146 b.h.p. and 140 b.h.p. respectively at 1,700 r.p.m., with additional ratings of up to 170 b.h.p. (gross) at 2,200 r.p.m., compared with 125 b.h.p. (net) at 1,800 r.p.m. in the case of the old engine.

An equally striking increase is seen in the case of the new 0.680 engine, which now has gross and net ratings of 210 b.h.p. and 200 b.h.p. respectively at 2,000 r.p.m., compared with the earlier net rating of 150 b.h.p. at 2,000 r.p.m. Torque ratings also have been raised, the 0.600 now developing 430 lb.-ft. at 1,200 r.p.m. (410 lb.-ft. at 900 r.p.m. formerly), whilst the 0.680 produces 548 lb.-ft. at 1,200 r.p.m., against 450 lb.-ft. at 1,100 r.p.m.— a remarkable increase.

Specific fuel-consumption rates have improved slightly. and all these advantages have been obtained for the most part merely by modifying the inlet and exhaust porting and manifolds and changing the shape of the combustion space in the piston crowns. The previous engines had toroidal cavities in the pistons, but by modifying the profile at the base of these cavities, improved combustion characteristics have been obtained. The new shape is known as Spheroidal. Brake mean effective pressures have been raised to approximately 120 p.s.i., compared with about 113 p.s.i. for the earlier engines.

Other relatively small changes concern the fuelinjection systems, the 0.600 engine having a mechanical governor, whilst the 0.680 has a hydraulic governor. Dry

New Leyland Maximumcapacity Four-, Sixand Eight-wheelers Announced: Completely New Designs Have Many Interesting Features .• Rear engined Single decker

cylinder liners are t etained for both engines, but those used in the 0.680 have chromium-plated bores.

Throughout the new range the 0.600 engine at its " economy " 1,700 r.p.m. rating is the standard power unit. Whilst this has ample power to give entirely satisfactory operation in this country with maximum fuel economy and longevity, it can be obtained with higher ratings, or the 0.680 engine can be installed. In all cases the installation includes twin paper-element air cleaners and an improved cooling system incorporating a wax-type thermostat and a rubber-cowIed fan which prevents recirculation of hot air through the radiator block.

High Torque Output

A similar 16.25-in.-diameter hydraulically operated clutch is employed with each engine. The high torque output of the 0.680 unit necessitates stronger clutch springs, however, so the hydraulic circuit is air-assisted to reduce pedal effort.

The standard gearbox is a new five-speed constant-mesh unit designed for unit-mounting with the engine. Its forward ratios are 7.243, 4.613, 2.755, 1.69 and 1 to 1, with a reverse ratio of 6.5 to 1. An overdrive ratio of 0.766 to 1, engaged by the main gear lever, can be supplied, as can a crawler bottom gear of 9.31 to 1, which is con trolled by a separate lever. Either or both of these additional ratios may be specified.

The overdrive section is installed on the rear of the gearbox, whilst the crawler gear is at the front and forms, in

effect, a second set of constantmesh gears. Thus, it could take effect on all the other ratios, although it is not recommended for use in this role. It can, however, be -employed to provide an extra-low reverse ratio of 8.36 to 1. A full torque and a 20-h.p. power take-off may be fitted and can be used while moving.

Hardy Spicer 1700-type propeller shafts drive into new douole-reduction axles which work on the same principle as the Albion axle used in the Super Comet but have higher load and torque capacities. The secondary epicyclic gear trains are in the hubs, and have five planet gears and a reduction ratio of 3.46 to 1. Overall axle ratios are changed at the spiral-bevel primary reduction gearing, and the standard overall ratios offered are 7.74, 6.06 and 4.82 to 1.

When a double-drive bogie is fitted the leading driving axle incorporates an air-operated lockable third differential, and the drive from this to the second axle passes through the casing of the leading axle.

Two types of rear-bogie suspension are available. One is a non-reactive four-spring layout, in which the rear ends of the springs on each side are linked by a system of bell-crank levers and tie rods so that the tendency for either axle to lift under braking or driving torque is counteracted by the similar tendency of the other axle to do so also. This arrangement not only gives better braking and tractive adhesion, but should help to improve tyre life.

The other suspension system employs two inverted semielliptic springs with free ends which rest on the axle spring brackets. The springs are centrally pivoted to the chassis frame on rubber trunnion bushes, and the axles are located by a system of parallel torque rods. This layout is similar to that originally introduced on the Leyland Buffalo heavy-duty six-wheeler and is fully proved.

Power-assisted steering is standard on all models, for which purpose both engines have a hydraulic pump driven from the timing-gear train. Marles camand double-roller steering gear carried in a Leyland box and incorporating the control valves for the power ram, is used, and the standard ratio throughout the range is 28.5 to 1, giving 4+ turns of the steering wheel from lock to 1

OCk

Semi-elliptic springs, 54-in, long, support the front axles of Beaver and Hippo models, whilst the Octopus chassis have similar springs on their leading axles and 48-in.-long springs on the second axles. In all cases telescopic' dampers are standard equipment on the front axles.

Air-pressure braking is employed throughout the range, and an innovation is the use of single-pull, air-assisted hand -brakes. The brake units are similar to those on Super Comet and Leyland underfioor-engined_ passenger chassis, and a drum diameter of 15.5 in. is common to all models. All front brakes have 4.5-in.-wide linings, whilst rear-brake linings are 7 in. wide.

Beaver models have a total frictional area of 632.3 sq. in., whilst Hippo and Octopus models have a total area of 1,002 sq. in. A single-circuit system controlled by a Dl valve has been used, and the S-cam brakes are actuated by diaphragm units working through Bendix Westinghouse slack adjusters.

Recognizing the poor handbrake performances of some current heavy goods vehicles, Leyland engineers were determined to develop a satisfactory hand-brake mechanism which

would be light to operate-, but would still comply fully with legal requirements. As a result, all the new models have a single-pull lever which gives a mechanical advantage of 280 to 1, so that in the event of failure of the single diaphragm-type air servo, an effective brake is still available. With the servo in action a 20-1b. pull on the lever is equivalent to 150 lb. without assistance. The servo is controlled by a valve interposed in the rod linkage between the hand-brake lever and the relay crossshaft, the left end of which shaft is acted.on by the servo. The chassis frames of Beaver models have /5-g--in.-thick side members with a maximum depth of 9+ in. except in the case of the 17-ft. 6-in-wheelbase chassis, which has a frame, 11* in. deep. The frames of Hippo 201-1. 12R and 20H.13R and Octopus 240.9R and 240.10R models (those with four-spring rear bogies) are in. thick, with a maximum depth of llf in., whilst the heavier Hippo and Octopus chassis, all of which have two-spring rear

bogies, have frames with a maximum depth of 12 in. Bolting is used throughout the assembly of all frames. Flitch plates are employed on certain models and, a change from previous practice, a greater number of tubular cross-members is employed.

1. ENGINE.

H S. II

RPM

Ten-stud wheels are used on all models, and the standard tyres on home-market Beavers and Hippos are 10.00-20-in, (14-ply), with 11.00-20-in. (12-ply) equipment on export vehicles. All Octopus chassis have 9.00-20-in. (12-ply) tyres as standard. Beavers and Hippos have B7.5 wheels whilst Octopus chassis have B7.

A new design of two-piece 0 pressed fuel tank, similar to that employed on Comet and Super Comet chassis, has been adopted for the new range. The standard

20 capacity on haulage models is 48 gal., whilst tippers and tractive

450

so

60 40

units have 36-gal. tanks. The electrical equipment is 24v. The standard cab for the new range is almost identical with that employed on Albion Clydesdale and Chieftain models, having also a number of components common to the Cornet and Super Comet cab. It is all-steel, with entrance steps ahead of the front wheels.

A plastics-panelled version of this cab, identical in appearance but weighing 2 cwt. less, is offered for the first time. The moulded reinforced plastics panels, which include the roof, front and rear assemblies, doors and wings, are resin-bonded to the main frame members used in the all-steel version. These members include the deepdrawn, one-piece door frames, giving maximum rigidity.

Each cab can be equipped with a fresh-air heating and demisting system, whilst provision is Made also for the installation of radio, sun visor and flashing indicators. The underside of the cab and front wings and the interior of the door panels are given weather-sealing treatment during manufacture, and a front bumper bar is standard equipment.

Power-Plus 0.400 Engine

THE new 0.400 Power-Plus engine for use in the Super I Comet models has a capacity of 6.54 litres, the bore being 107.19 mm. and stroke 120.65 mm. Gross and net power outputs of 131 b.h.p. and 125 b.h.p. at 2,400 r.p.rn. are quoted, whilst the net torque output is 300 lb.ft. at 1,600 r.p.m.

The engine differs in several respects from the 0.375 unit which it replaces in the Super Comet. Not least of the differences is the use of Spheroidal combustion chambers in the piston crowns, Laystall Chromard thin-wall cylinder liners, and inlet and exhaust manifolds located on opposite sides of the cylinder head.

Another small but significant change is that parallelfaced piston rings are employed, as opposed to the wedgesection rings used in other Leyland engines. The wedge form was originally intended to prevent the rings sticking in their grooves, but modern detergent oils avoid this trouble, so dispensing with the need for rings of special section.

The fuel-injection pump is a Simms Mini in-line unit, and Leyland four-hole injectors are employed. The injec tion pump has a mechanical governor. Possible distortion of the cylinder head and gasket has been overcome by the use of five studs and a bolt equally spaced around each bore.

Workintaster+Atlantean=Lion

A WORLDMASTER chassis with an Atlantean rear end r-L forms the basis of the new Lion passenger vehicle. Its layout is similar to that of foreign vehicles which have proved popular with coach operators, in that the underfloor space between the axles can be used for luggage accommodation.

The Lion has a wheelbase of 20 ft., making it suitable for 34-ft.-long bodywork, and is available with leftor right-hand drive. The standard chassis has the 0.600 Power-Plus engine rated at 140 b.h.p., but the 0.680 210-b.h.p. unit can be fitted, and this will ix: seen in the Show exhibit, which is afterwards to be shipped to Highway Products, Ltd., Ohio, U.S.A.

As with the Atlantean, the power unit is mounted transversely in unit with a Pneumo-Cyclic four-speed semiautomatic gearbox and angle-drive box. The power pack is mounted in a detachable sub-frame which bolts to the rear frame extensions and to additional cranked channel members. The frame side members are reinforced with channel sections between the axles, whilst there are nine ' cross-members, eight of which have adjacent outriggers.

On standard 11.00-20-in. (12-ply) tyres the frame height is 34 in. Semi-elliptic-springs are standard equipment at both axles, with telescopic dampers at the 'front, but a leaf-air suspension system may be specified for the front axle. The S-cam air-operated brakes have a total lining area of 702 sq. in., and Leyland worm-and-nut steering gear is employed.

A new form of air filtration has been developed as optional equipment for this vehicle to combat the heavy dust pollution which prevails on unsurfaced roads overseas. Air is drawn in at the front of the vehicle at roof level and is ducted through the roof and out at the rear above the engine compartment. The air is then drawn into a multielement cyclone filter with more than 300 individual filter units, and this precipitates the finer dust particles into an underslung hopper. Thus only clean air is drawn into the engine compartment, for both cooling and breathing.

Like the Atlantean, the Lion can have an external engine compartment or one incorporated in the body rear styling to give a smooth line. For the former layout there is a plastics cowl incorporating faired fins with prominent rear lights and direction indicators. The Lion chassis has an unladen weight of 5 tons 19 cwt., and its gross weight rating is 133 tons.

THE new Leyland 0.400 oil engine described on this page has been adopted as the standard power unit in a new series of Albion Reiver 6 x 4 and 6 x 2 chassis. A form of the non-reactive bogie has also been developed. The 0.400 is to be used in the Clydesdale range.

A change has also been made with regard to the specification of Albion Nimbus and Claymore underfloorengined passenger and goods chassis. These models are in future to be equipped with the standard Albion five-speed constant-mesh gearbox as used in Chieftain, Clydesdale and Reiver chassis. This replaces the four-speed unit previously employed.

An exclusive road-test report of one of the new Reiver chassis will be published in next week's issue of The commercial Motor.