The British Berna Eighty-five-cwt. Chassis.

Page 6

Page 7

Page 8

If you've noticed an error in this article please click here to report it so we can fix it.

A New Model, Identical in the Main with its Swiss Predecessor, but Modified and Brought Up to Date.

Chassis bearing the name of Berna have for a decade been giving remarkably good service to commercial-vehicle users. Time and again, in discussing with users the reliability and service rendered by the vehicles in their possession, we have been assured by Berna users that their next machine would be

of the same make. Since the war began we have discovered, in the course of various interviews with users, that wherever the impressment officers have found a Berna available, their decision as to suitability has quickly been made. This make of machine stands high in the list of those which consistently give economic results, as well as continued running: without liability to frequent, or even occasional, breakdowns.

The First AB-British 3i-Tenser.

Until quite recently they were manufactured only in Switzerland. A year or two ago, however, the 5-termer began to be made in this country ; the 3i-tormer continued to be the Swiss Berna. Recently, however, we had the pleasure of being introduced to the all-British alj-ton Berna, and examined the first model at the British Berna Co.'s garage, Avonmore Road, West Kensington.

Existing Features Retained. The Special Type of Final Drive.

In view of what we have said above about the experiences of users, we deem it advisable to point out that the constructional features which have been the characteristic of this chassis for many years are to be retained. The final drive to the rear axle is of a type which was adopted by the earliest manufacturers of heavy vehicles. The Berne. Co. is one of the few who have con B24

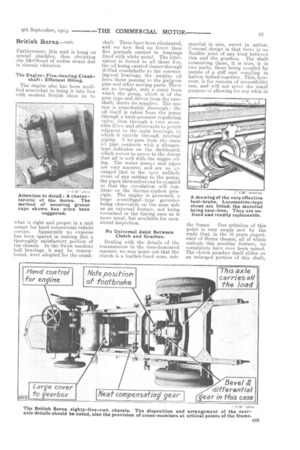

tinued to use it For those who are not acquainted with the details of this chassis, the following brief description of the final drive should be of particular interest. The rear wheels are fitted with drums containing internally-cut gears. With these mesh pinions carried by cross shafts, themselves driven from the normal type of differential, the whole being carried in a casing supported by what are termed perch bars. The drive from the propeller shaft is by means of a pair of bevels, through the differential to these cross shafts? and thence to the internal gears in the rear wheels. The actual loadbearing axle is an entirely separate one, as in the case of a chain-driven machine. In fact, in the opinion of many people this type of drive is the best compromise between the heavy double-reduction live axle with a huge casing carried on a load-bearing axle and the other form, wherein the final drive is by roller chains to sprockets bolted to the rear road wheels, which themselves run on a separate dead axle. The advantage of the internal gear as against the chain drive is, in the first place, the fact that no chains are needed, and that the mechanism can be suitably enclosed, and in a manner much simpler than that possible where chains are adopted for the final drive. Of one thing there is no doubt ; that is, that the Berna Co. has made a suc cess of this drive. The new allBritish machine, therefore, includes it amongst its specific constructional features.

Improvements in Detail : The Radiator.

The chassis, it must be agreed, is a very fine example of commercialmotor-vehicle design. Outstanding points of difference between the British and Swiss Bernas there are none. The improvements referred to are rather in the matter of detail, but none the less important on that account.

We might first of all mention the radiator. In the original machine this is, as our readers will probably know, of the honeycomb type, the cooler being enclosed in a casing of pressed metal. Nowadays that form of radiator is looked upon with a considerable amount of suspicion, and we are glad to note that it has been dropped, and that the more sensible form embodying cast top and bottom headers with vertical tubes has now been adopted Furthermore, this unit is hung on special shackles, thus obviating any likelihood of undue strain due to chassis vibration.

The Engine: Five-bearing Crankshaft : Efficient Oiling.

The engine also has been modified somewhat to bring it into line with modern British ideas as to what is right and proper in a unit meant for hard commercial-vehicle service. Apparently no expense has been spared in making this a thoroughly satisfactory portion of the chassis. In the Swiss machine ball bearings, it may be remembered, were adopted for the crank-

shaft. These have been eliminated, andwe now find no. fewer than five journals carried in bearings lined with white metal. The lubrication is forced to all these five, the oil being carried thence through drilled crankshafts to the connecting-rod bearings, the surplus oil frorti these passing to the gudgeon pins and other moving parts. There are no troughs, only a sump from which the pump, which is of the gear type and driven from the camshaft, draws its supplies. The system is remarkably thorough ; the Oil itself is taken from the pump through a back-pressure regulating valve, then through a very accessible filter, and afterwards to points adjacent to the main bearings, to which it travels through internal piping. A by-pass from the main oil pipe connects with a Plungertype indicator on the dashboard, which serves to prove to the driver that all is well with the engine oiling. The water pumps and pipes are very massive, and are so arranged that in the vsry unlikely event of any mishap to the pump, the pipes themselves can be coupled so that the circulation will continue on the thermo-syphon principle. The engine is governed, a large centrifugaltype governor being observable on the near side as an external feature, not being contained in the timing case as. is more usual, but available for occasional inspection.

No Universal Joint Between Clutch and Gearbox.

Dealing with the details of the transmission in the time-honoured manner, we may point out that the clutch is a leather-lined cone, sub

stantial in size, sweet in action.. Unusual design is that there is no flexible joint of any kind between this and the gearbox. The shaft connecting these, it is true, is in two parts, these being coupled by means of a stiff cast coupling in halves, bolted together. This, how-. ever, is for reasons of accessibility one and will not serve the usual purpose of allowing for any whip in the frame. Our .criticism of this point is very amply met by the reply that, in the 10 years experience of 13erna chassis, all of which embody this peculiar feature, no complaints have ever been raised. The clutch member itself slides on an enlarged portion of this shaft, being guided thereon by splines. These are very deep, evidently with the idea of providing ample wearing surface. The clutch spring is an external one, very accessible in case of need for adjustment.

Four.-speed Box. Accessible Internals.

The gearbox is provided with four speeds and reverse. With the exception of the top-speed gear, these are all engaged by sliding longitudinally one into another. As one of our illustrations shows, the box itself is provided with an unusually large cover. We were informed, and we are quite willing to believe, from conclusions drawn from our own observations, that it is possible to remove the whole of the mechanism from this box without taking it from its position in the chassis. From gearbox to rear axle the transmission is by the usual type of propeller shaft with block and trunnion-type joints at both ends. The final drive we have already described.

Enormous Brakes.

The brake gear on the chassis is an exceptional feature. The foot brake takes effect through the locomotive-type shoes on a drum carried in front of the bevel gear. Any braking strains, therefore, are taken by the propeller shaft and jnints: This brake is exceptionally effective in operation, the leverage provided is rather more than the usual, and the drum itself is of a good size. As can be seen from one of our drawings, the adjustment is very accessible arid should be very effective. The brake shoes themselves are of cast-iron, and

when worn can be very quickly renewed. The rear brakes almost justify the adjective enormous. Previously it has been the company's practice to utilize the external portion of the drums carrying the internal gears for the purpose of applying band brakes. On the British model this practice has been discarded, and instead advantage is taken of the inside of the rims of the road wheels, these providing a brake drum of something like 30 ins. diameter. Here again no renewable linings are provided with the shoes. It is expected, and we think with some justification, that these brake shoes will probably outlast the chassis. Friends of the Barna Co. will be interested to note that deliveries of this machine are to be made in the early part of October, the demands of the War Office being satisfied by the Swiss company, which is pro viding large number regularly, so that harassed users may look forward to additional relief from present troubles if immediate advantage be taken of this opening.

Results of W.D. Tests.

The following extracts from a report which is the result of an official test by the War Office may be interesting :—

" The total weight of chassis, body and load amounted to 7 tons 18 cwt., of which :31 tons were metal bars, six persons being carried in addition.

" Twenty-three-and-a-half miles were covered in 87 minutes, the average speed being 16i miles per hour.

The petrol consumed amounted to 2.6'25 gallons, equivalent to nine miles per gallon ; the ton-mileage per gallon reached the most creditable figure of 70.