The right lightweight

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

Cummins 14-litre engine was often criticised for its weight but it looks as though the firm has put matters right with its new 10-litre six-cylinder turbo. Graham Montgomerie reports

AT THE NEC, in two weeks time, operators will have their first chance to see the new 10-litre six-cylinder turbocharged engine from Cummins.

Designated the "right weight lightweight" the new engine is claimed to offer light weight combined with a compact design, good fuel economy and up to 800,000km (500,000 miles) reliability and durability.

Cummins has announced that the engine will be available in Bedford, ERF, Foden, Leyland and Seddon Atkinson lorries in addition to passenger vehicles from Bombardier, MCW and Sisu.

The 10-litre develops 186kW (250bhp) at 2,100rpm to BS AU 141a gross, with a maximum torque to the same standard of 1017Nm (750Ibft) at 1,300rpm.

As a guide to installed power, a figure of 180kW (241bhp) is claimed for the Seddon Atkinson 301.

In this 250 horsepower form, the Cummins will be known as the LT10-250, with L being the engine series number and T meaning turbocharged.

The 250 horsepower version is aimed at tractive units and eight

wheelers although Cummins will also offer a de-rated version at 164kW (220bhp) for six-wheelers.

Moving into the city bus market, effectively for the first time, Cummins will be making a 134kW (180bhp) version with a maximum engine speed of 1,850rpm. (These figures may already be familiar to bus operators!) The maximum torque of the bus version is 813Nm (600Ibft) at 1,000rpm.

A criticism that can be made of the highly successful 14-litre Cummins engine — and one which is accepted by its manufacturer — is of its weight and bulk. In NTE 290 form, the 14litre has proved very popular but in its lower-powered versions has not been very competitive with the "lightweight 32-tonners" typified by the F7. Cummins has answered this criticism with the 10-litre.

The net dry weight of the engine is 850kg (1,8751b) which compares with the 1,160kg (2560Ib) of the 14-litre. Perhaps a more logical comparison would be with the Gardner 6LXCT at 858kg (1,8881b).

One of the Cummins design priorities was to keep the overall package as small as possible (and I'll deal with how this was achieved a little later). The overall length of the 10-litre is 1248mm (49.1in) and its width is 805mm (3.7in). One of the most important engine dimensions is overall height, which Cummins has managed to get down to 997mm (39.23 in).

The specific fuel consumption for the engine in 250 horsepower form is 206g/kWh (0.341Ib/bhph) at its rated speed of 2,100rpm which improves to 199g/kWh (0-328Ib/bhph) at maximum torque. Cummins claims that this latter figure is equivalent to a thermal efficiency of over 43 per cent. Externally the engine looks extremely clean because of its comparative lack of external pipework, with the inlet manifold, for example, being incorporated as part of the rocker cover. Thus, as far as the outside of the engine is concerned, there is no inlet manifold.

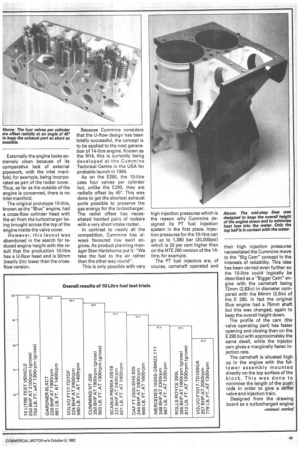

The original prototype 10-litre, known as the "Blue" engine, had a cross-flow cylinder head with the air from the turbocharger being brought across the top of the engine inside the valve cover.

However, this layout was abandoned in the search for reduced engine height with the result that the production 10-litre has a U-flow head and is 50mm (nearly 2in) lower than the crossflow version. Because Cummins considers that the U-flow design has been totally successful, the concept is to be applied to the next generation of 14-litre engine. Known as the N14, this is currently being developed at the Cummins Technical Centre in the USA for probable launch in 1984.

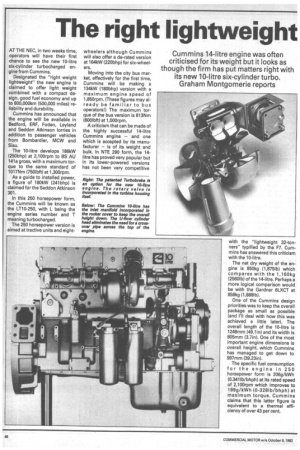

As on the E290, the 10-litre uses four valves per cylinder but, unlike the E290, they are radially offset by 450. This was done to get the shortest exhaust ports possible to preserve the gas energy for the turbocharger. The radial offset has necessitated handed pairs of rockers with a very short intake rocker.

In contrast to nearly all the competition, Cummins has always favoured low swirl engines. As product planning manager Stan Hartshorne put it: "We take the fuel to the air rather than the other way round".

This is only possible with very high injection pressures which is the reason why Cummins designed its PT fuel injection system in the first place. Injection pressures for the 10-litre can go up to 1,380 bar (20,000psi) which is 33 per cent higher than on the NTE 290 version of the 14litre, for example.

The PT fuel injectors are, of course, camshaft operated and their high injection pressures necessitated the Cummins move to the "Big Cam" concept in the interests of reliability. This idea has been carried even further so the 10-litre could logically be described as a "Bigger Cam" engine with the camshaft being 72mm (2.83in) in diameter compared with the 64mm (2.5in) of the E 290. In fact the original Blue engine had a 75mm shaft but this was changed, again to keep the overall height down.

The profile of the cam (the valve operating part) has faster opening and closing than on the E 290 but with approximately the same dwell, while the injector cam gives a marginally faster injection rate.

The camshaft is situated high up in the engine with the follower assembly mounted directly on the top surface of the block. This was done to minimise the length of the push rods in order to give a stiffer valve and injection train.

Designed from the drawing board as a turbocharged engine — Cummins has no intention of producing a naturally aspirated version — the 10-litre has its top gas ring far closer to the top of the piston than is usual. This was done for better utilisation of the air space in the combustion area and, while Cummins would have preferred to have the ring even higher from a combustion point-of-view, mechanical considerations dictated the final .position.

The cylinder liner is another interesting design feature of the new Cummins. It is officially described as a "mid-stop" liner with the upper part only being of the wet type. The lower part is not in contact with the cooling water but nor is it fitted directly into the parent bore of the block so it cannot really be called a wet/dry liner hence Cummins' use of the term mid-stop.

The liner is located rigidly at the bottom of the short water jacket by means of a machined seat, and a straightforward press fit is used at the top. Holes cast into the water jacket provide a direct jet of coolant on to the upper part of the liner.

The mid-stop liner was designed partly to keep the water jacket short and thus reduce the overall height of the engine but mainly to minimise heat loss into the water. The mid-stop liner is designed for easy replacement in-frame if required with only one seal to replace.

The integral fan is driven from the camshaft gear train, with its engagement controlled by water temperature. The physical engagement is by means of a multiplate clutch actuated by the

engine lubricating oil. No maintenance is required for the fan drive which is mounted under the front gear cover.

Conscious of the poor reputation of most exhaust brakes in service, Cummins has installed its patented Turbo-brake in the 10-litre. This consists of a rotary valve in the exhaust turbine housing itself thus being integral with the whole turbocharger assembly. When actuated, the valve rotates thus closing off the exhaust flow.

As far as maintenance is concerned, injector and valve adjustments are required once a year or every 96,600km (60,000 miles). The Cummins engineers claim that the gear drives for the fan, water and oil pumps and the compressor eliminate the potential unreliability and the maintenance requirements of belt drive systems.

Gear drives are inherently noisier in operation than belt drives but Cummins maintains that the overall noise level is within its programmed target thanks to the use of a non-metallic rocker cover and scalloping of the main block casting.

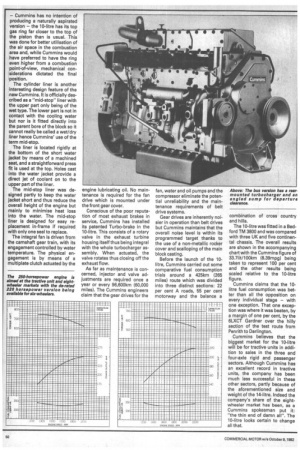

Before the launch of the 10litre, Cummins carried out some comparative fuel consumption trials around a 425km (265 miles) route which was divided into three distinct sections: 22 per cent A roads, 55 per cent motorway and the balance a combination of cross country and hills.

The 10-litre was fitted in a Bedford TM 3800 and was compared with three UK and five continental chassis. The overall results are shown in the accompanying chart with the Cummins figure of 33.71it/100km (8.39mpg) being taken to represent 100 per cent and the other results being scaled relative to the 10-litre figure.

Cummins claims that the 10litre fuel consumption was better than all the opposition on every individual stage — with one exception. That one exception was where it was beaten, by a margin of one per cent, by the 6LXCT Gardner over the hilly section of the test route from Penrith to Darlington.

Cummins believes that the biggest market for the 10-litre will be for tractive units in addition to sales in the three and four-axle rigid and passenger sectors. Although Cummins has an excellent record in tractive units, the company has been much less successful in these other sectors, partly because of the aforementioned size and weight of the 14-litre. Indeed the company's share of the eightwheeler market has been, as a Cummins spokesman put it: "the thin end of damn all". The 10-litre looks certain to change all that.