Compact bodies with lift

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

by Bryan Jarvis While Japan's automo tive engineering moguls wrestle with the problems of satisfying environmental needs, its bodybuilders have come up with a variety of ways of building more compact trucks.

Many operators require vehicles that are a little easier to load. Isuzu displayed its Forward Three-Way tail tilting or fully elevating body system, which is a clever method of loading plant: other loading systems elevate the entire vehicle, using hydraulic legs behind the cab to lift and lower the chassis about its rearmost axle.

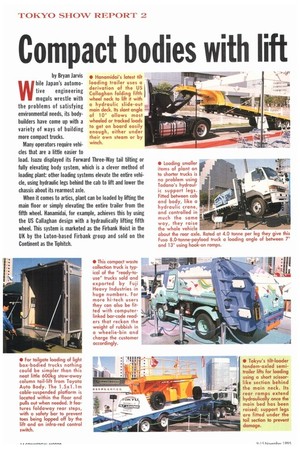

When it comes to artics, plant can be loaded by lifting the main floor or simply elevating the entire trailer from the fifth wheel. Hanamidai, for example, achieves this by using the US Callaghan design with a hydraulically lifting fifth wheel. This system is marketed as the Firbank Hoist in the UK by the Luton-based Firbank group and sold on the Continent as the Tiphitch. • Hanamidai's latest tilt loading trailer uses a derivation of the US Callaghan folding fifth wheel neck to lift it with a hydraulic slide-out main deck. Its slant angle of 10' allows most wheeled or tracked loads to get on board easily enough, either under their own steam or by winch. • Loading smaller items of plant on to shorter trucks is no problem using Tadano's hydraulic support legs. Fitted between cab and body, like a hydraulic crane, and controlled in much the same way, they raise the whole vehicle about the rear axle. Rated at 4.0 tonne per leg they give this Fuso 8.0-tonne-payload truck a loading angle of between 7' and 13° using hook-on ramps.

• This compact waste collection truck is typical of the "ready-touse" trucks sold and exported by Fuji Heavy Industries in huge numbers. For more hi-tech users they can also be fitted with computerlinked bar-code readers that reckon the weight of rubbish in a wheelie-bin and charge the customer accordingly.

• For tailgate loading of light box-bodied trucks nothing could be simpler than this neat little 600kg stow-away column tail-lift from Toyota Auto Body. The 1.5x1.1m cable-suspended platform is located within the floor and pulls out when needed. It features foldaway rear steps, with a safety bar to prevent toes being lopped off by the lift and an infra-red control switch. • Tokyu's tilt-loader tandem-axled semitrailer lifts for loading using a short scissorlike section behind the main neck. Its rear ramps extend hydraulically once the main bed has been raised; support legs are fitted under the tail section to prevent damage.