Public Service Garages.

Page 7

Page 8

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

Thomas Tilling, Limited, was the first omnibus company to adopt motor omnibuses in London. A MiInes-Daimler omnibus was purchased, and placed on the Peckham-Oxford Circus route thirteen months ago. This line originally belonged to Mr. Thomas Tilling exclusively, but in recent years it has become "associated," the service being worked jointly by Thomas Tilling, Limited, Patsy Hearn, and the Star Omhibus Company. The first motor bus proved so successful that an order was placed for further machines with the same builders, and arrangements were then made for a suitable permanent garage to accommodate them. A site was arranged close to Winchester House, the headquarters of the Company.

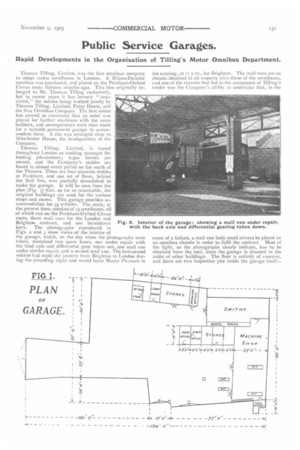

Thomas Tilling, Limited, is famed throughout London as ranking amongst the leading job-masters; 6,5oo horses are owned, and the Company's stables are found in almost every parish on the south of the Thames. There are four separate stables at Peckham, and one set of these, behind the Bull Inn, was partially demolished to make the garage. It will be seen from the plan (Fig. I) that, as far as practicable, the original buildings are used for the various shops and stores. This garage provides accommodation for 35 vehicles. The stock, at the present time, consists of is omnibuses, all of which run on the Peckham-Oxford Circus route, three mail vans for the London and Brighton contract, and one breakdown lorry. The photographs reproduced in Figs. 2 and 3 show views of the interior of the garage, which, on the day when the photographs were taken, contained two spare buses, one under repair with the hind axle and differential gear taken out, one mail van under similar repair, and a second mail van. The last-named vehicle had made the journey from Brighton to London during the preceding night and would leave Mount Pleasant in the evening, at mm p.m., for Brighton. The mail vans are on chassis identical in all respects with those of the omnibuses, and one of the reasons that led to the acceptance of Tilling's tender was the Company's ability to undertake that, in the

event of a failure, a mail van body could always be placed on an omnibus chassis in order to fulfil the contract Most of the light, as the photographs clearly indicate, has to be obtained from the roof, since the garage is situated in the midst of other buildings. The floor is entirely of concrete, and there are two inspection pits inside the garage itself

see Fig. 1. There are two more inspection pits in the large machine shop, at the end of the garage, so that, whtn a chassis is undergoing a complete overhaul, it can be run over one of them. All the omnibuses enter at the smaller gates (bottom of Fig. /), and stand so that they are ready to leave in their proper order each morning from the main gates shown to left of the plan. They alt come in during the middle of the day for replenishments, and for the men to have their dinner, and they can always come in at the end of any journey should their stock of petrol be running low, or for any other purpose, because the garage is so close to the terminus.

The repairing plant has been arranged with a view to dealing with a service of too omnibuses, and it is probably as complete as that of any workshop attached to an omnibus service in England. It is intended to make all the spare parts in the shops, and the stores already contain a duplicate of practically every part of a Milnes-Daimler omnibus. There is, consequently, less delay over replacements and repairs than would be

the case were the .organisation less effective. The workshop contains a join. Lang lathe, a 6in. Lang lathe, and an 81,in. Bradford lathe. Two of these lathes are visible at the left-hand side of the photograph reproduced in Fig. 4, but the largest lathe is still further to the left and beyond the limits of the picture. A Cincinnati universal cutter grinder is in the immediate foreground, and somewhat obscures the view of a No. 3 Cincinnati double universal milling machine. This milling machine is an extremely useful tool : it is kept busy with gear wheels, pinions, etc. A 26in. upright Barnes drill will be noticed to its right, and the shop also contains a Sigourney sensitive drill—one of the most valuable labour-saving appliances that any shop can contain. There is a Hills twist drill grinder and, in the foreground, a Star power hack-saw. A number of steel ingots for axle gudgeons are just in front of the hack-saw, and, at the time the photograph was taken, one of these was being cut to standard length. There is also a bench emerygrinder and a brazing forge in this shop where the whole of the plant, in addition to that in the smithy, is driven by a 6h.p., alternating current, single-phase, electric motor which will supply ample power even when further machine tools are laid down. A door will be noticed, at the end of the shop, leading into the smithy, and a powerful tyre press, which is more clearly shown in Fig. 5, is visible through it. This is a 6o-ton press by Tangye, of Birmingham, and is the first

to be installed for the purposes in view. Most of the other omnibus companies in London have ordered similar presses since it has been laid down. The bed plate is sunk well into the floor, and the pumps for operating it can be seen to the right. A cast-steel Milnes-Daimler back wheel, which somewhat interferes with the outline of the controlling cocks, is against the wall, behind the press. The foreman had just pressed off a pair of Polak tyres, from the wheel which has been referred to, during the time of our representative's visit. These had been in use for over 7,000 miles, and were worn down toa thickness of 'in. The pressure required to force them off the wheel, as shown on the pump gauge, was 47 tons. There would be a considerable danger that these tyres would work off on the road unless they were pressed on very tightly. This hydraulic press is proving one of the most valuable tools which can be specified as part of the equipment for an omnibus garage, as parts of many systems are put together by pressing the collars and wheels on to the shafts. A gas oven for annealing and case-hardening purposes will be seen in the left corner. A large floor—at present almost vacant—is over the machine shop; only the tinsmith who repairs the radiators, lamps, etc., and does other light sheet-metal work, and the body repairer, work there, but it can be used for fitters' benches as soon as necessity arises. There is a special tool store on the right of the machine shop for the lodging of twist drills, reamers, milling cutters, jigs, etc. All tools are issued on the check system, each man being provided with a limited number of brass checks, and when a tool is issued the check is put in its place until the tool is returned to stores. This is the simplest and most reliable system of checking tools. There is a tyre store on the upper floor, above the workshop, capable of holding ion sets of omnibus tyres.

The plan (Fig. 1) shows that the stores are divided into three separate compartments : this is because they were originally stables. The dividing walls have proved extremely useful for shelving, the stores being rendered unusually accessible; one partition is devoted to tools, the second to ball bearings, brasses, and small parts, and the third to gear wheels, machine castings, springs, and the larger spare parts. The shape of the stores does not, unfortunately, lend itself to the production of a satisfactory photograph, and we are, as a consequence, unable to show the extreme neatness and precision with which everything is accommodated and arranged so as to render it an extremely easy

matter to find any particular part without loss of time. The engineer's and clerks' offices are next to the stores, but it is the intention of the Company to construct larger and more commodious premises by the side of the garage. These two rooms will then become additional store space.

The petrol store is at present licensed to contain 1,000 gallons, stored in two-gallon tins, but four large tanks are to be installed in this store at an early date, so that 2,000 gallons can be delivered and kept in bulk. Vig. 6 shows the plan and elevation of this store, with its pipe connections. The delivery hose from the wagon pump couples on A, and the petrol can be directed by cocks to any one of the four tanks. The hand-pump shown can be made to suck, similarly, from any one of the four tanks, and to deliver to any vessel for the purpose of conveyance to an omnibus. The whole of the motor premises are lighted by electricity : smoking or naked lights are strictly prohibited. The omnibuses are lighted by acetylene gas, which is supplied compressed into cylinders. These cylinders are changed. every three days, the operation being clean and occupying little time. Illuminated destination signs are provided, the lighting being done in the same way, and each omnibus carries a New Era fire extinguisher.

Another large garage is in construction in the south of London to provide for future extensions, and we shall hope to illustrate and describe this at a later date.

The motor department is under the charge of Mr. Percy Frost Smith, who has been identified with motor omnibuses from their first inception. He was a pupil of Mr. Alfred Dickenson, of Birmingham. In 1899 he was managing the service of double-deck motor omnibuses between Kennington and Oxford Circus, but this was a somewhat premature effort. His management of the motor department at Peckham has developed that branch of Tilling's business to its present encouraging stage, and it is due to his careful supervision that no omnibuses run more regularly than those on the Peckham-Oxford Circus route. Mr. Smith, as engineer, has the following staff under him :—A yard foreman, four fitters, four fitters' mates, three turners, two machine hands, two labourers, two clerks, one store-keeper, and, one draughtsman, on day work ; a foreman, three fitters, three litters' mates, three greasers and cleaners, and three washers, on night duty.

When the Soc. M.O. Eng., of whose council Mr. Frost Smith is a most active member, takes up its summer programme of visits, we feel sure that the members of that body will not spend a more interesting afternoon than at the Peckham establishment of Thomas Tilling, Limited, in the event of an invitation being extended by the directors.