Taking the lid off buses in boxes

Page 60

Page 61

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

As home markets dwindle, manufacturers are boxing clever and setting their eyes on more distant horizons. Sending bus body kits overseas for self-assembly is a growing business, as Noel Millier reports

WORLD relies increasingly ransport and new skills in 'building are constantly bedeveloped to manufacture s to satisfy ever escalating ands.

established public transnetworks decline in Britain, of crucial importance that lanufacturers seek avenues seas.

Iny developing countries built up the domestic busing industries, and many of coachbuilders have benefrom co-operation with h manufacturers, new techniques have been loped and materials have me available, both compo; and expertise has been exd to various world markets. tat Sections famous buses}OX system has its direct mdant in Duple (Metsec) The original organisation -ted bus bodies in kit form arly 40 years.

ov within the Duple group, .c's wide experience in the n and building of bus bos linked with Duple (Coachars) successful fully built-ige of luxury coach bodies. )Ie (Metsec) bodies are ded to fit most chassis in the . Since 1951, Metsec has

over 5,500 single deck s and 3,000 double-deck. Lally part of the Tubes Investment (TI) group, Metsec is the only UK bodybuilder with continuous experience of overseas bus-body assembly.

Currently the company offers a steel single-deck body kit and mostly aluminium double-deck body. Both models normally come complete with fully finished interior trim.

Duple (Metsec) is at present supplying body kits for Kowloon Motor Bus Company in Hong Kong. The first kit in the current batch arrived in Hong Kong last March, and the first bus was completed on Dennis Jubilant bus chassis by April 1 and successfully passed its tilt test just five weeks later.

A production line is now being set up to enable 20 double-deck bodies a month to be produced.

Duple (Metsec) has recently supplied double-deck body kits to both KMB and China Motor Bus in Hong Kong, Singapore Bus Services, and PPD of Indonesia. Chassis include Leyland Atlantean and Dennis Jubilant.

Single-deck body kits have been supplied to JOS in Jamaica, PUTC in Pakistan, SBS and UBZ in Zambia. Chassis used include Leyland, Volvo, Mercedes-Benz and Nissan.

The company can also supply kits consisting of basic frameworks only to allow the use of increased local material while still ensuring strength and safety. Duple (Metsec) stresses it is committed to export markets and its experience ensures that local assembly can take place quickly without the use of jigs.

All components are shipped in batches together with an assembly plan. All parts are individually numbered and cut to shape to ensure that sections can be readily bolted and riveted together by unskilled labour.

But Duple (Metsec) now faces major competition from companies both at home and abroad. Its longest established British competitor is undoubtedly Walter Alexander at Falkirk in Scotland.

In 1975 when most British bus bodybuilders were recovering from a famine of chassis supplies, Alexander offered CMB a completely knocked down (ckd) kit version of its British body design.

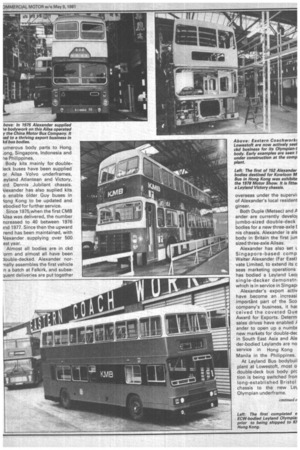

In 1975, Alexanders supplied the first Ailsa double decker body to Hong Kong and has been going strong ever since. Since this first export Alexander body, the company has supplied iumerous body parts to Hong ;ong, Singapore, Indonesia and he Philippines.

Body kits mainly for doubleleck buses have been supplied or Ailsa Volvo underframes, .eyland Atlantean and Victory, ind Dennis Jubilant chassis. klexander has also suplied kits o enable older Guy buses in -long Kong to be updated and .ebodied for further service.

Since 1975,when the first CMB Visa was delivered, the number ncreased to 40 between 1976 )nd 1977. Since then the upward rend has been maintained, with lexander supplying over 500 ast year.

Almost all bodies are in ckd 'orm and almost all have been Jouble-decked. Alexander normally assembles the first vehicle in a batch at Falkirk, and subsequent deliveries are put together

overseas under the supervi! of Alexander's local resident gineer.

Both Duple (Metsec) and A ander are currently develoi jumbo-sized double-deck bodies for a new three-axle [ nis chassis. Alexander is als body in Britain the first jun sized three-axle Ailsas.

Alexander has also set k.•

Singapore-based comp Walter Alexander (Far East) vate Limited, to extend its c seas marketing operations has bodied a Leyland Leo' single-decker demonstr; which is in service in Singapf Alexander's export activ have become an increasi importa'nt part of the Sco company's business, it ha ceived the coveted Que Award for Exports. Determ sales drives have enabled ander to open up a numb( new markets for double-clec in South East Asia and Ale der-bodied Leylands are no service in Hong Kong Manila in the Philippines.

At Leyland Bus bodybuil plant at Lowestoft, most double-deck bus body prc non is being switched fron long-established Bristol chassis to the new Le Olympian underframe. Eastern Coachworks believe it the new all alloy body for :Olympian is ideally suited for her complete and particularly i kit supply to overseas mars.

ECW plant director John iore told CM that he is actively king ckd business, and emasised that ECW, while being nis manufacturer/Leyland )up company is still finanIly autonomous it will not n unfair advantage over its npetitors in overseas markets le shape of BL subsidies.

.CW's new Olympian-type iy will be suitable for fitting to ssis from other manufacturas well as Leyland, said John ore.

e gave the assurance that V's ckd business would be : of a planned plant expanprogramme and overseas .omers would not suffer if e was a sudden upturn in the market. ECW's jig construcs will enable the company to 3Iy the pre-drilled body cornants in various stages with nany sub-assemblies corn?.d as required.

;W is currently supplying built-up buses on Leyland ipian chassis for operation Dng Kong and is looking for In business in the newly

established South-east Asia bus markets.

Although not usually associated with bus exports, ECWbodied Bristol FCF buses have been sold second-hand to countries in Africa, North America and South-east Asia.

Metro-Cammell-Weymann in Birmingham has a capacity of over 1,000 complete buses per year. MCW's New Generation Metrobus is widely accepted by operators in both Britain and Hong Kong, where a fleet of long-wheelbase jumbo deckers are among the 52 in operation.

MCW has recently delivered the first two of the current quota of three-axle jumbo buses ordered by Hong Kong operators. The 12m buses feature a new rationalised integrally designed body which is lighter, simpler and stronger than the present Metrobus.

Modular in concept the stressed aluminium structure uses three kinds of aluminium extrusion and just two designs of connecting brackets which, together with full use of the fibreglass mouldings, make it both strong and suitable for vehicles of varying wheelbase and body lengths.

The new MCW has both interior and exterior roof panels produced to a common length, and the whole structure has been designed to be suitable for easy ckd assembly should this be needed.

As well as the big boys, Britain has a number of smaller, basically single-deck, bus body manufacturers who can supply vehicles in either ckd or practically knocked-down kit form.

British bus operators are now familiar with the Wadham Stringer Vanguard bus body produced at Waterlooville in Hampshire, and from this design the company has evolved its Valiant export body concept.

Wadham Stringer is setting up a new production plant at Stanton in Suffolk from where it can supply Valiant single-deck bodies either fully built up, partially knocked down or ckd. The company has designed low-cost jigs to enable up to ten bodies per month to be built. If a higher output is needed the company can supply jigs (or design the formation to build jigs on site) to enable the body to be assembled as one unit and actually mounted onto the chassis in the jig.

Each jig system of this type is designed to assemble up to 20 bodies per month.

A detailed manual is supplied with each kit. It includes part lists, component and assembly layouts, as well as build sequence instructions.

The Valiant structure comprises a combination of standard modules welded together to form a reinforced multiple-ring ;emi-monocoque construction iesigned to carry up to 7 tonnes pf roof luggage and passenger lensities of up to ten people per square metre.

Wadham Stringer's high output jig for the main body com prises two "goal posts" on rithich are mounted hydraulic rams, valves and mounting frames for the roof jig and side jigs. The jigs can be used in manufacturing bodies on any chassis of any length. Chassis model changes are made by fit ting the relevant front and rear sections to the centre section of the body side.

The body structure is similar above the solebar on all chassis types except for numbers of standard-sized bays and entrance positions. Below the sole bar the bodywork is easily repai rable and added after main body construction. Wadham String er's Valiant is skimmed in aluminium or sheet steel except for the front and rear domes, which are grp, and the bonnet cover and headlamp surrounds.

The first prototype Valiant is being assembled at Stanton on a Leyland Viking chassis before being shipped to Ghana as a Leyland demonstration vehicle_ In Northern Ireland, Wright Brothers of Ballymena offers its Wright TT bus body system in knocked-down form for overseas assembly.

Wright uses the Alu-Suisse body construction system which allows simple assembly and a particularly strong structure without the need to employ any skilled staff or expensive jigs.

Lex Vehicle Engineering of Totton, near Southampton, manufactures a full range of single-deck bus and coach bodies, including an articulated vehicle, in its Maxeta vehicle range. Lex can supply most of its range in ckd or partially built kit form.

The company can supply bodies in various stages of construction to suit customer requirements.

Plaxton of Scarborough has been supplying luxury ckd coach bodies since 1975, and a number of Supreme vehicles have recently been exported to Australasia.

The British world of ckd bus body kits is expanding as coachbuilders widen their horizons to counter declining demands at home. Yet bus body manufacture is not a British perogative. Most countries, both developed and developing, have domestic bus bodying capabilities. Which British exporters to compete, must provide that extra something — quality, safety, strength and reliability.

But exporting should not be regarded merely as a stopgap solution to the current recession. It is the lifeblood of the British bus industry.