NEW ROLLER BEARINGS FOR HEAVY DUTY.

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

Introduction of a New Set of Bearings for Road Wheels Carrying Heavy Loads. Bearings Renewable_ by Unskilled Labour.

UNTIL recently the use of anti-friction bearings for the hubs of the heavier class of commercial motors has not been considered an unqualified success. It is true that many vehicles are fitted with this class. of bearing, but the large proportion of heavy motors still being made with plain bearings to the hubs may be taken as a proof that the anti-friction bearing has not entirely made its ease good. The advantages of antifriction bearings over plain bearings can hardly be denied so far as the saving in fuel is concerned, yet in spite of this saving we see plain bearings still used in so many instances. The use of plain bearings is known to produce wear on both axle and hub, and the fitting of a new floating sleeve to mating surfaces, which are scored, is by no means a satisfactory job, whilst difficulties are also experienced when fitting new plain sleeves, because the wear on hub and axle is not even all along the length of the bearing. When the hole in the hub is gauged, it is often found to be tapered—that is, larger at one end than the other, according to the position of the central line of the wheel in relation to the bush.

It has been claimed as an advantage that anti-friction

eFFECT Or WEAQ N 40lt !

e lry,4471,ralair NON 12G-1OLVING I 1 teVD

NEW 1:4151-1

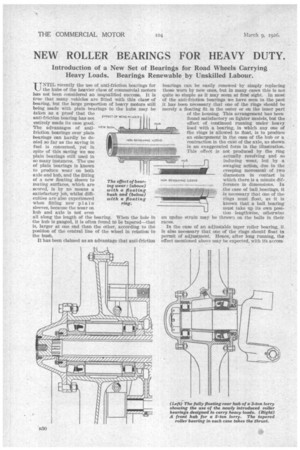

The effect of bearing wear: (above) with a floating bush and (below) with a floating

ring.

bearings can be easily renewed by simply replacing those worn by new ones, but in many cases this is not quite so simple as it may seem at first sight, in most of the anti-friction bearings we have seen in the past it has been necessary that one of the rings should be merely a floating fit in the outer or on the inner part

of the housing. This arrangement has been found satisfactory on lighter models, but the effect of continued running under heavy load with a bearing, in which any one of the rings is allowed to float, is to produce , an enlargement in the case of the hub or a contraction in the case of the axle, as shown in an exaggerated form in the illustration.

This effect is not produced by the ring actually revolving and so inducing wear, but by a swaging action, due to the creeping movement of two diameters in contact ia which there is a minute difference in dimensions. In the case of ball bearings, it is necessary that one of the rings must float, as it is known that a ball bearing must take up its own position lengthwise, otherwise an undue strain may be thrown on the balls in their races.

In the case of an adjustable taper roller bearing, if is also necessary that one of the rings should float to permit of adjustment. Hence, after long running, the effect mentioned above may be expected, with ifs accom.

HUB

211fjfaillfffftgllr___ NON izEvo1..vm4G LtEV

panying difficulty when renewing a ring, as it is apparent that no new bearing can work satisfactorily in a housing or on an axle unless it be a close fit.

Adjustable bearings have proved themselves of great use on the lighter fortes of motors, but on the heavier types there is difficulty in accurately. adjusting them so as to be sure that they carry the load properly and at the same time are not screwed up too tightly, as in any such case the bearing is called upon to bear a very great stress for which it is not designed. The difficulty of adjustment arises from the fact that heavy lorry wheels are of such great weight that the mechanic cannot feel properly to what degree of pressure he is adjusting the bearing.

The S.K.F. heavy-duty roller bearing appears to have been designed with a view to avoiding certain defects that have been found to exist in some designs of anti-friction bearing intended for use on the heavier types of motors for their hubs.

The sectional views show the application of the prin ciple to front and rear hubs. In the case of a rear hub, the double-row roller bearing is towards the outside, whilst in the front hub it is near the inside. The object is to place the double-row hearing in the-position where it carries the greater portion of the load. It will be seen that in this arrangement, unlike most anti-friction bearings, none of the rings is allowed to float. Alt are firmly gripped, consequently no wear should take place either in the housing or on the .axle ; the floating action necessary to all such bearings is taken by the parallel-type bearing, which has no restraining influence laterally its outer ring having no flanges to locate the rollers. All ead thrusts and its share of load are borne by the double-row roller bearing. The design of the double-row, bearing has had special attention paid to it, and it will be seen that the outer ring is spherical in its inner surface, the curve being struck from the centre of the bearing, as shown in the diagrammatical view. The curve of the rollers does not permit of contact with the outer member along their whole length, a slight clearance being allowed towards the ends of the rollers and the outer ring by means of the former being shaped to a curve struck from a centre 3 per cent, short of that of the outer ring. The inner ring is formed so that the rollers contact for their full length. The object of this, is to relieve the outer ring front complete contact for greater freedom, as the outer ring offers a concave surface to the rollers, and to ensure greater wearing qualities in the inner ring, which offers a convex 'surface to the rollers, and is, consequently, more liable to abrasion.

The rollers are formed so. that they follow a true path, not in a straight line, but following a cone, as shown in the diagrammatical view. The outer ends of the rollers are concave, whilst the inner ends are convex. Owing to this feature, the rollers are enabled to roll without undue rubbing action on the bottom or sides of the groove. It has been found that, in certain circumstances, the rolling speeds of two sets of rollers mounted together may not be equal; so, to prevent any binding of the cages, it has been found beneficial to form the cages in two separate pieces, as shown. in the sections of the hubs on the previous page.

It may be said that there is not much possibility of bearings mounted so close to each other as those in hubs being misaligned, or of flexure in the shafts, but with roller bearings of such large diameter as those suitable for heavy work, the slightest error will throw an undue strain on both rollers and ring surfaces.

To obviate an undue strain, the spherical principle is maintained in the double-row bearing, whilst In the single-row the outer' ring is slightly convex in its bore, so that any slight error of alignment would not affect its running, fly the introduction of these two provisions for misalignment, which may be due to poor machining, flexure, or bending through accident, a bearing is provided which will run perfectly, even under unfavourable conditions,

The Effect of Wear on Housing and Axle.

As will be seen from the sectional views,both inner and both outer rings are firmly gripped by means of nut and distance sleeve in the case of the inner and by flanges in the case of the outer. The effect of this is to prevent the slightest wear from taking place between the rings and the non-renewable parts, so that such parts should be practically everlasting.

Unlike many anti-friction bearing arrangements, this type can have either of its bearings renewed by any person Without skill, as no fine adjustment or spacing of the bearings is needed. In case of a renewal, all that one has to do is to place the bearing in position and screw up as tightly as possible, as the bearing is selfsetting for lateral position and alignment.

To be able to renew a bearing with unskilled labour is sometimes of great service to a lorry owner, as in many places skill or the judgment necessary for adjustment cannot be relied upon.

Another advantage in being able to screw an axle nut up tightly is that the nut at the end of an axle or axle sleeve is less likely to strip its thread than when it lies loosely on an axle and is only prevented from revolving by its engagement with a detent.